Simulation bench equipment for automobile engine camshaft test

A technology of automobile engine and simulation bench, applied in the direction of engine testing, mechanical equipment, engine components, etc., can solve the problems of high cost, loss, precious bench resources, etc., to achieve low cost, accurate wear resistance and reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

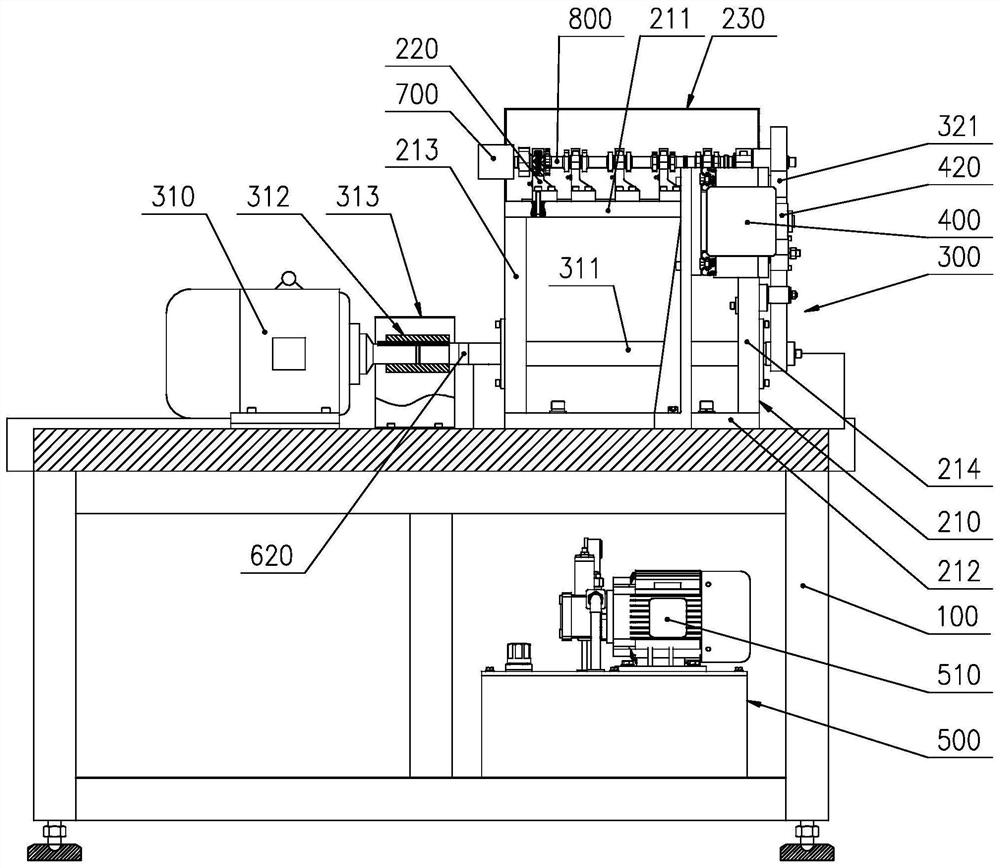

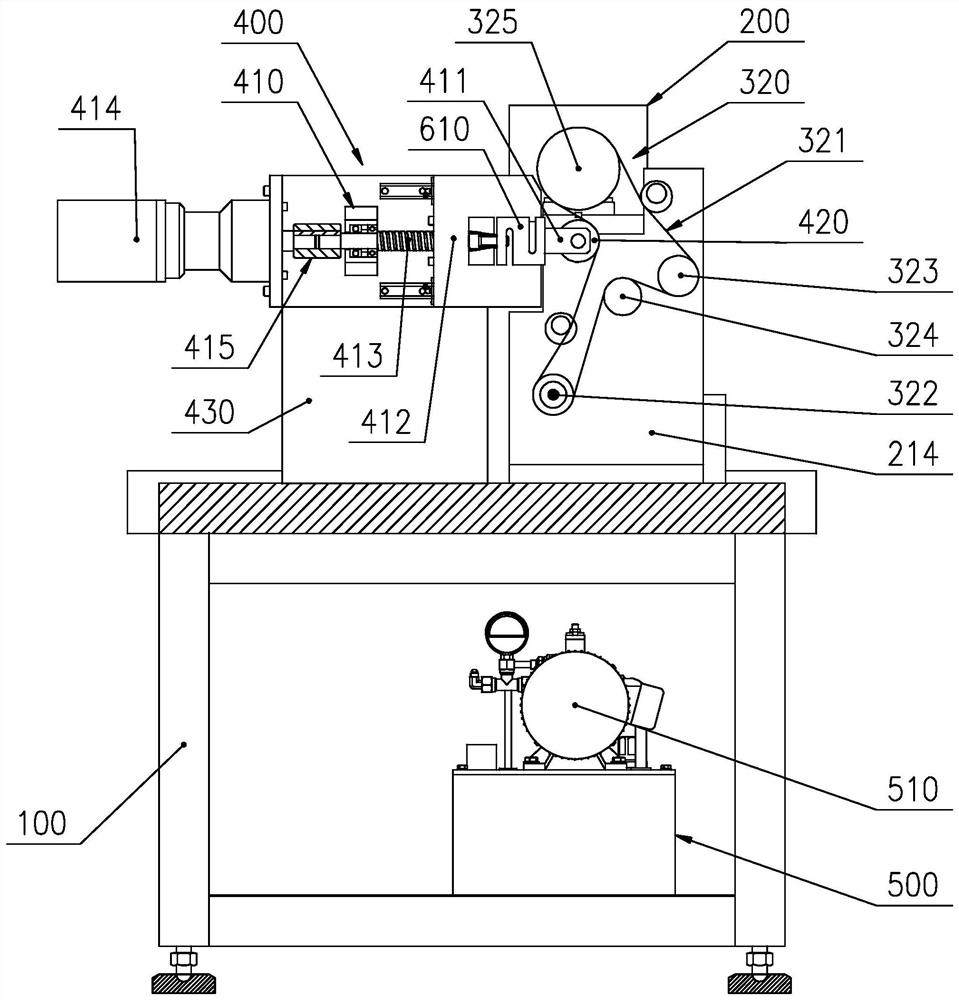

[0024] combine figure 1 with figure 2 As shown, the simulated bench equipment for automobile engine camshaft test includes equipment frame 100, camshaft mounting assembly 200, driving device 300, load system, oil supply system 500 and monitoring system;

[0025] The camshaft mounting assembly 200 includes a machine frame 210 arranged on the equipment frame 100 , a camshaft mounting seat 220 arranged on the frame top plate 211 of the machine frame 210 and a frame top plate 211 covered on the frame frame 210 A camshaft cover 230 that covers the camshaft mounting seat 220, the camshaft mounting seat 220 is provided with a pulley 325 for transmission connection with the automobile engine camshaft 800;

[0026] The driving device 300 includes a driving motor 310 and a belt transmission mechanism 320; the driving motor 310 is in transmission connection with the pulley 325...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com