Electroplated carbon fiber lead mesh grid and its manufacturing method

A production method and carbon fiber technology, applied in circuits, electrical components, battery electrodes, etc., can solve the problems of low production efficiency, complex process, large lead consumption, etc., and achieve the effects of increased strength, simple preparation process, and reduced lead consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

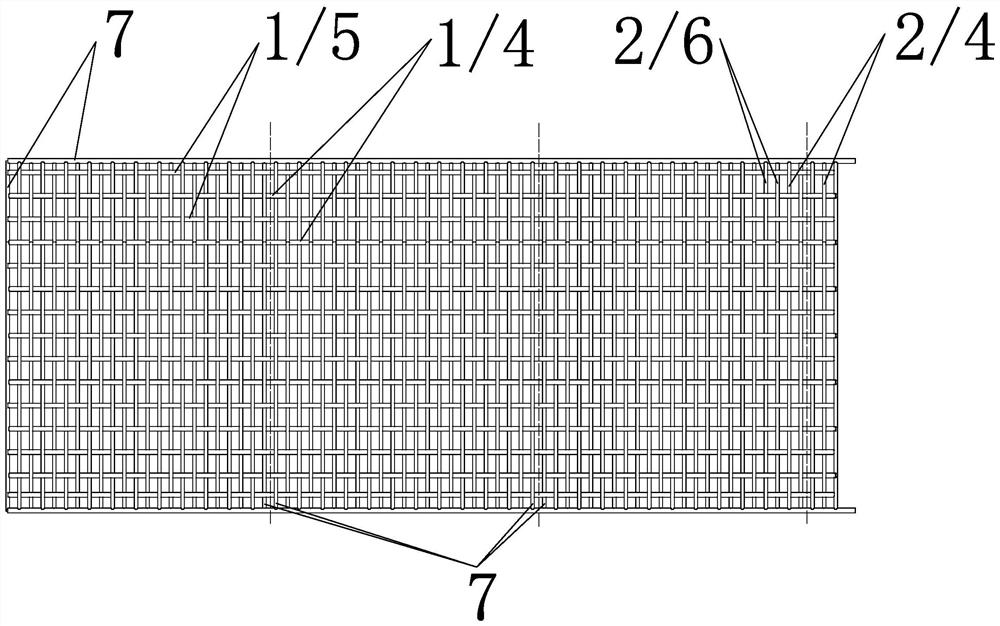

[0026] like figure 1 As shown, an electroplated carbon fiber lead mesh grid of the present invention includes a square grid 3 woven from several evenly distributed warp threads 1 and uniformly distributed weft threads 2, and several pieces of the grid 3 are connected end to end. connected to form an integrally connected belt-shaped structure, wherein the warp 1 is formed by carbon fiber filaments 4 and warp plastic filaments 5 at intervals, and a warp plastic filament 5 is sandwiched between two adjacent carbon fiber filaments 4 corresponding to the warp 1. The weft 2 is composed of carbon fiber filaments 4 and weft plastic filaments 6 at intervals. Two adjacent carbon fiber filaments 4 corresponding to the weft 2 are juxtaposed with two weft plastic filaments 6. The adjacent warp 1 and the adjacent There are gaps between the wefts 2, and the corresponding warps 1 and wefts 2 around the edges of each grid 3 are enclosed to form a carbon fiber wire frame 7, and the carbon fiber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com