A large cabinet circulation heat dissipation structure that melts and solidifies

A technology of circulating heat dissipation and cabinets, which is applied in the construction of electrical equipment components, cooling/ventilation/heating transformation, electrical components, etc., can solve the problems of reduced service life of electrical components, reduced server operating speed, hidden safety hazards, etc., to accelerate heat dissipation The effect of distributing, avoiding potential safety hazards, and accelerating dissemination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

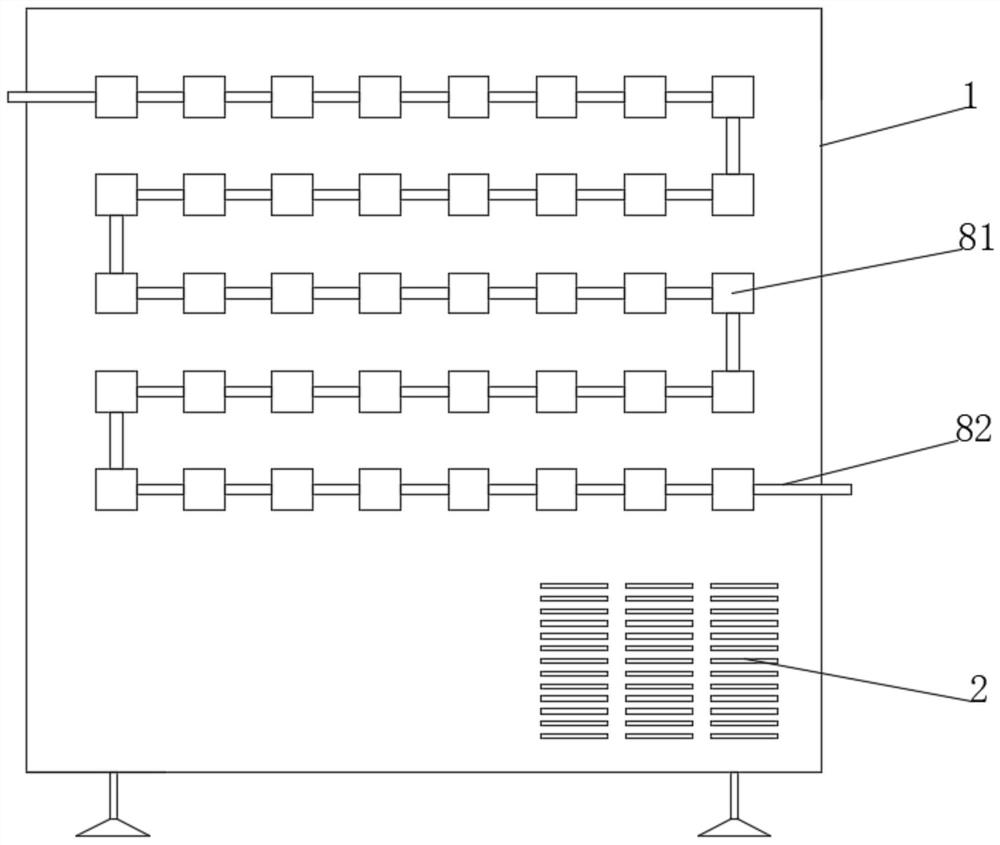

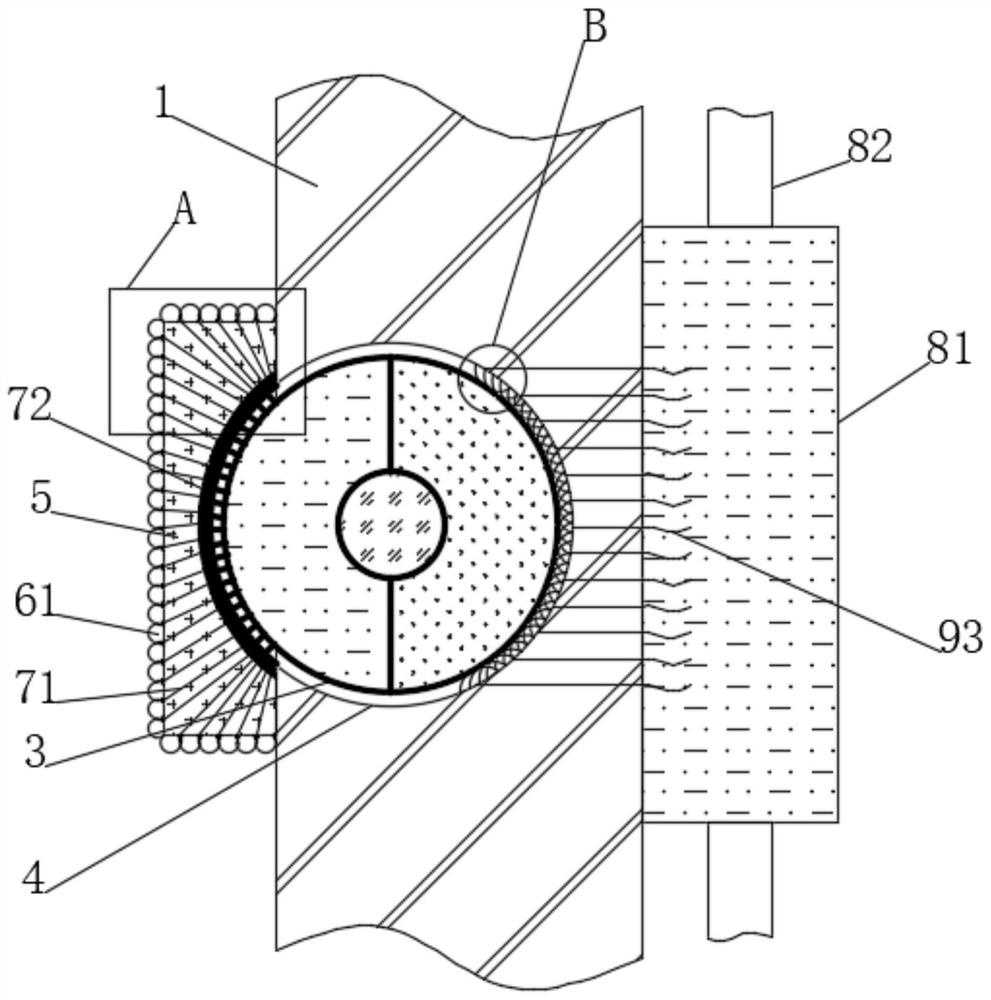

[0039] see figure 1 , a melting and self-solidifying large-scale cabinet circulation heat dissipation structure, including a heat dissipation hole 2 excavated at the lower right end of the cabinet 1 and a plurality of embedded ball holes 4 excavated in the inner wall of the cabinet 1, the outer surface of the cabinet 1 is fixedly connected with a plurality of uniformly distributed The heat removal block 81, two adjacent heat removal blocks 81 are fixedly connected to each other with a heat removal rod 82, the heat removal block 81 and the heat removal rod 82 are connected to each other, and a plurality of heat removal blocks 81 and heat removal rods 82 are composed of The circulating condensation channel can continuously circulate the condensed water to accelerate the heat dissipation.

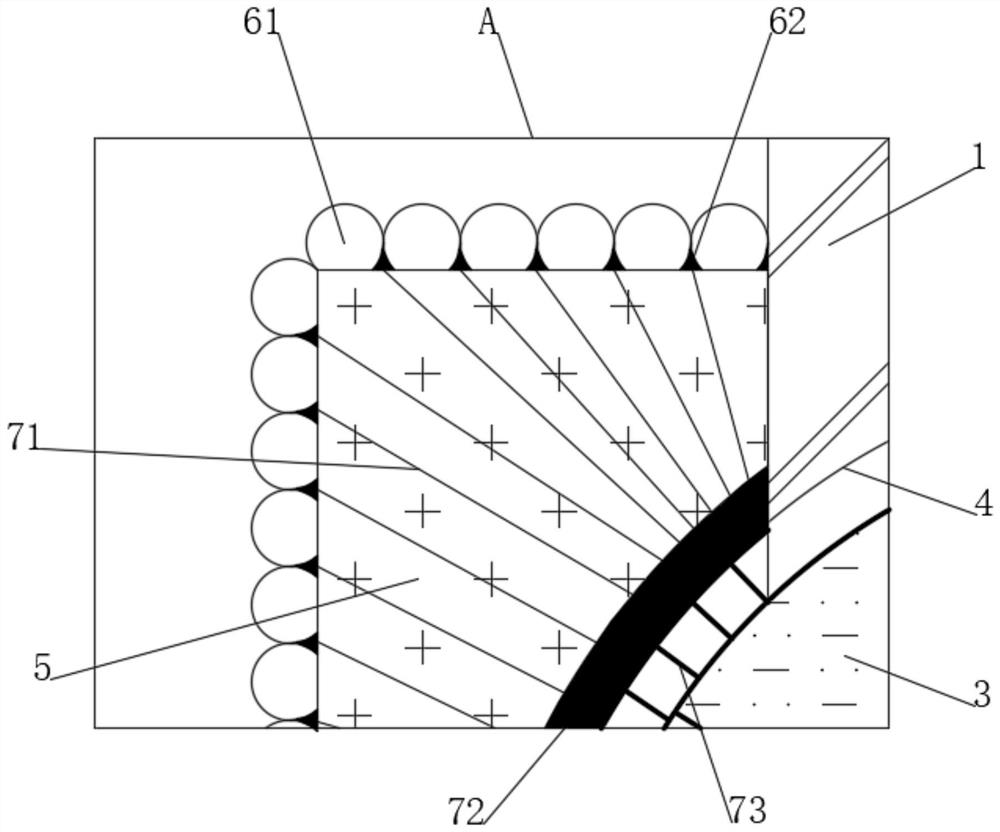

[0040] see figure 2 , the mouths of the plurality of embedded ball holes 4 are all facing the inside of the cabinet 1, the interior of the embedded ball holes 4 is connected with a dual-stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com