High-speed railway ballastless track shifting connection structure

A technology of ballastless track and high-speed railway, which is applied in the field of rail transportation, can solve problems such as the inability to guarantee the quality of convenient track, and achieve the effects of shortening track connection time, ensuring transportation capacity, and saving direct engineering investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

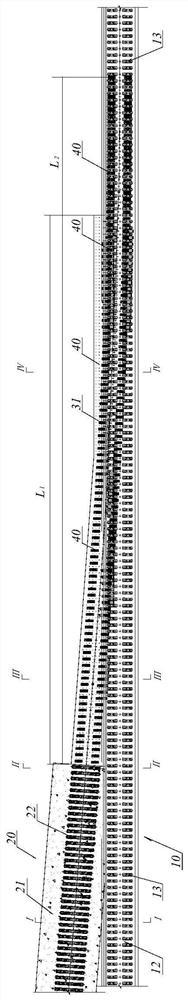

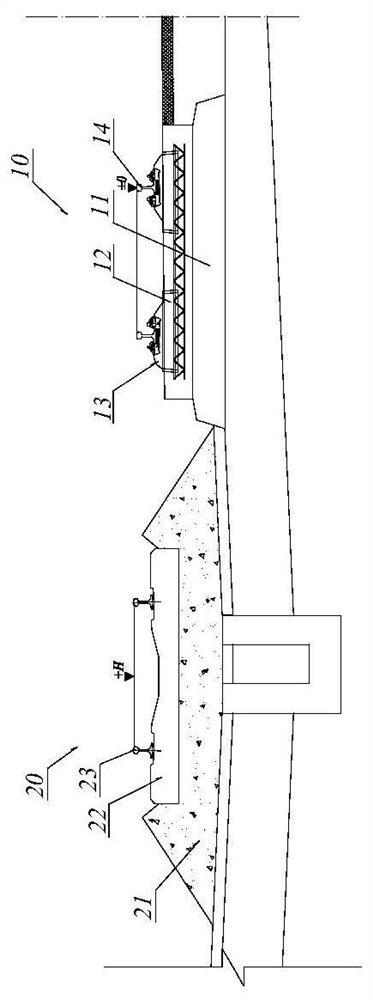

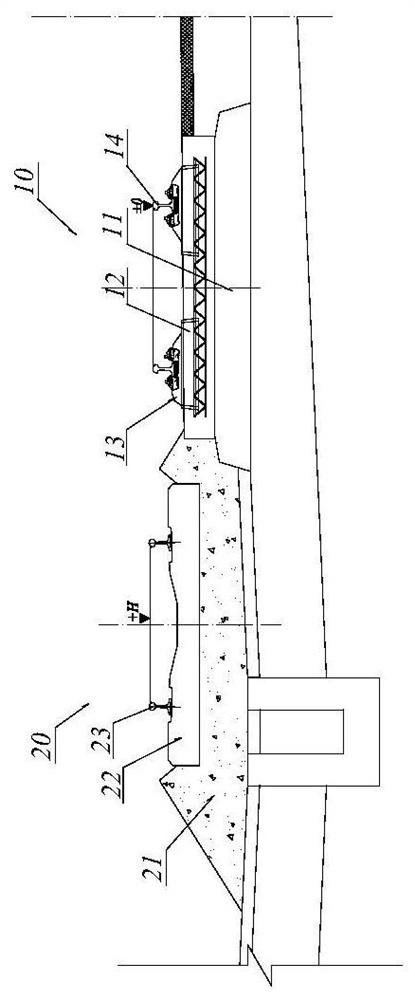

[0021] refer to Figure 1 to Figure 5 , a high-speed railway ballastless track dial connection structure of the present invention, comprising a main line ballastless track 10 and a ballasted track line 20 located on one side thereof. The main line ballastless track 10 includes an existing ballastless track bed 12 located on a supporting layer 11, and an existing double-block sleeper 13 is fixedly arranged on its upper part. The ballasted track toilet line 20 is composed of a ballasted track bed 21 and a sleeper 22, and a transition section L is set between the main line ballastless track 10 and the ballasted track toilet line 20 1 As the basis for transitional dialing of the convenience line, the transition section L 1 The main body is the reinforced concrete widened track bed 30 poured on the outside of the existing ballastless track bed 12 . The tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com