Fully-fabricated standardized temporary support structure and construction method

A temporary support and full assembly technology, which is applied in the direction of pillars, building structures, and building materials, can solve the problems of damage to the standard section of the tower crane, large erection area, troublesome installation process, etc., so as to improve the bearing capacity and stability. Satisfy support requirements and improve stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further elaborated and illustrated below in conjunction with the accompanying drawings and specific embodiments. The technical features of the various implementations in the present invention can be combined accordingly on the premise that there is no conflict with each other.

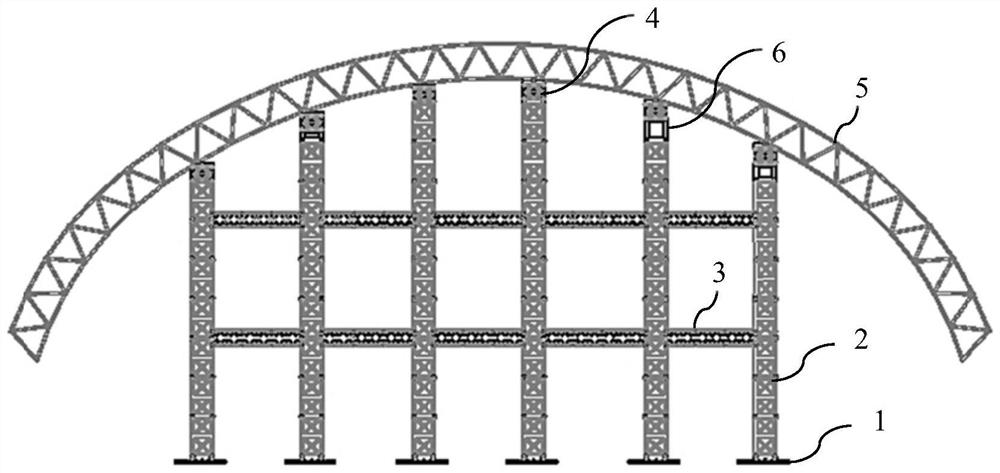

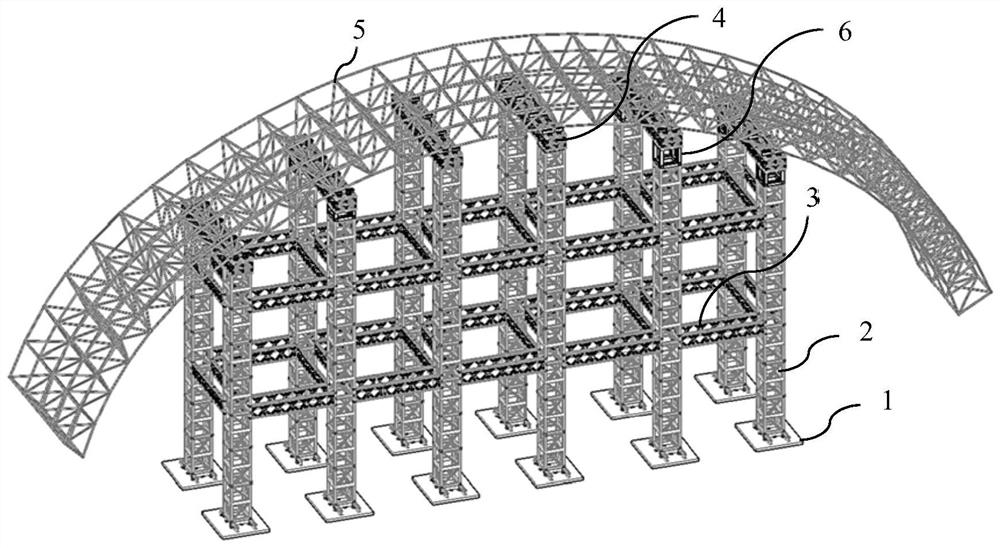

[0053] Such as figure 1 with 2 As shown, in a preferred embodiment of the present invention, a fully assembled standardized temporary support structure is provided for temporarily supporting the space structure 5 .

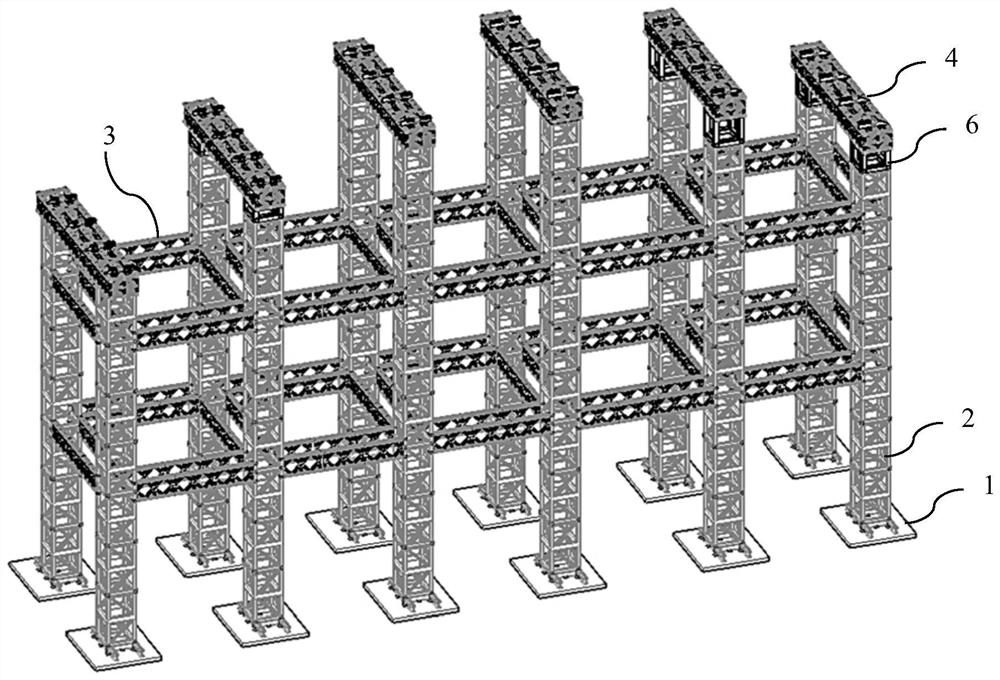

[0054] Such as image 3 As shown, the main structure of the standardized temporary support structure includes a bottom connection structure 1 , a tower crane standard section 2 , a connecting Bailey frame 3 and a top support frame 4 . There are multiple bottom connecting structures 1, which are evenly distributed in the installation site of the temporary support structure. A support column is formed by installing a plurality of vertically assembled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com