Water leakage detection device and water leakage searching method for heat exchanger in annealing furnace

A detection device and heat exchanger technology, which is applied in the direction of detecting the appearance of fluid at the leakage point, the water content of materials, and the use of liquid/vacuum for liquid tightness measurement, etc., which can solve the problems of inaccurate detection values, short detection time, Long detection time and other problems, to achieve the effect of short detection time, save detection time and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

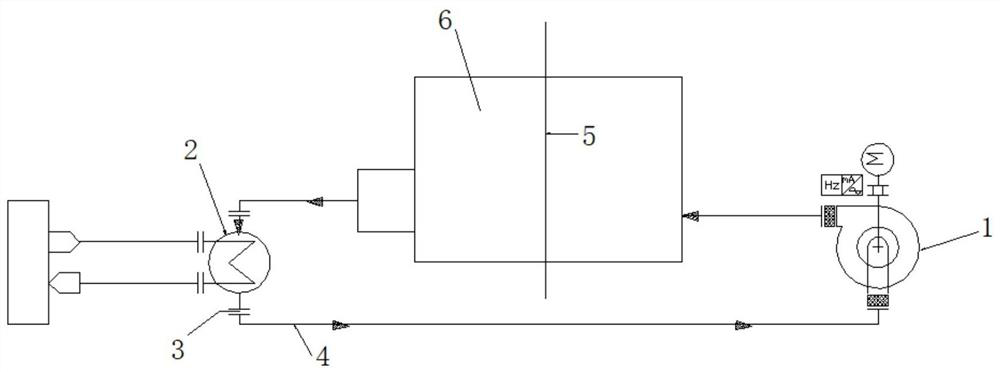

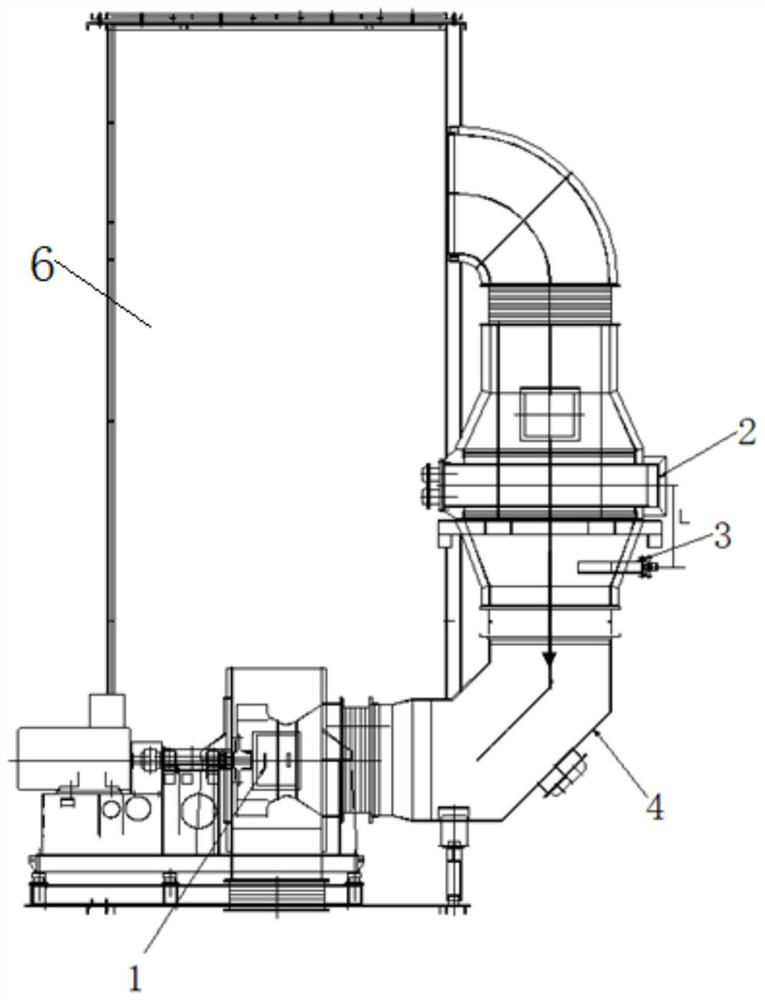

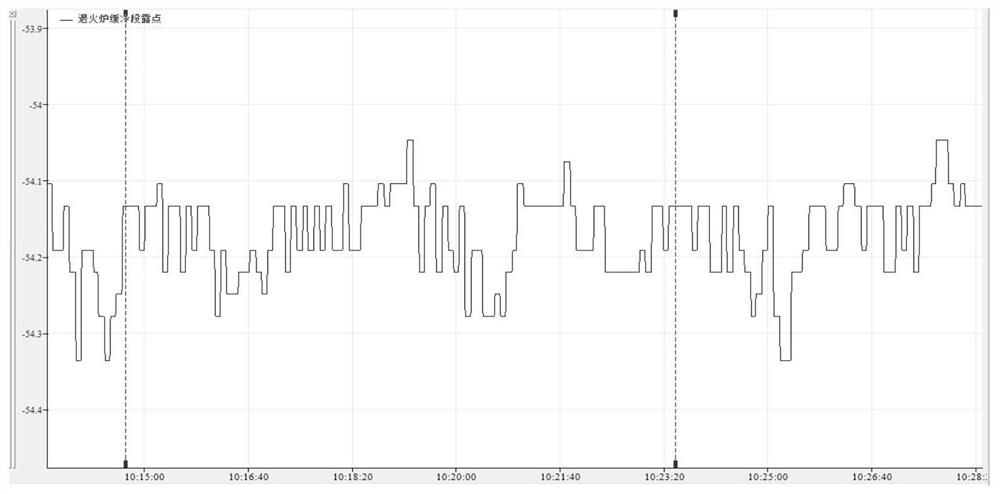

[0029] The heat exchanger in the cooling section of the cold-rolled vertical continuous annealing furnace is a water-cooled heat exchanger 2. A water leakage detection device and a water leakage search method for a heat exchanger in an annealing furnace in this embodiment are as follows: figure 1 and figure 2 As shown, it includes a water-cooled heat exchanger 2 and a dew point detector 3. The water-cooled heat exchanger 2 is installed on the air outlet of the furnace 6, and the air inlet of the furnace 6 is equipped with a cooling fan 1. The water-cooled heat exchanger 2 and the The cooling fan 1 is communicated through the cooling pipe 4; the dew point detector 3 is installed at the outlet of the water-cooled heat exchanger 2, and the atmosphere in the cold rolling vertical continuous annealing furnace is a nitrogen-hydrogen protective gas, and the nitrogen-hydrogen in the furnace 6 The protective gas is controlled by the cooling fan 1, cooled by the water-cooled heat excha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com