Full-automatic cable insulation thermal shrinkage sample preparation device

A technology of cable insulation and heat shrinkage, which is applied in the field of fully automatic cable insulation heat shrinkage sample preparation device, can solve the problems that the skill level of the sample quality test personnel is greatly affected, the sample preparation method is time-consuming and laborious, and it is difficult to achieve standardization, so as to avoid Safety risks, safe and reliable sample preparation process, and convenient sample clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

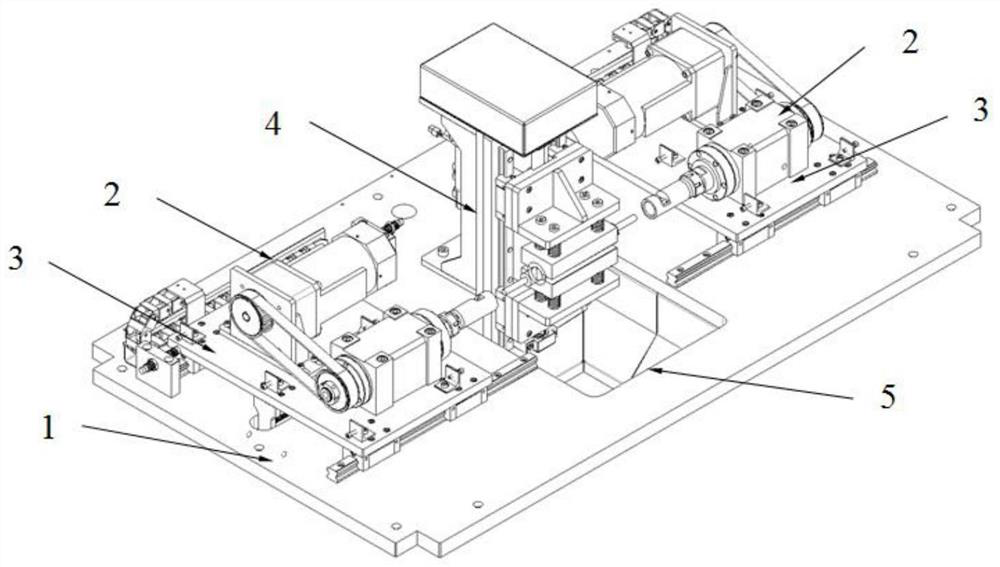

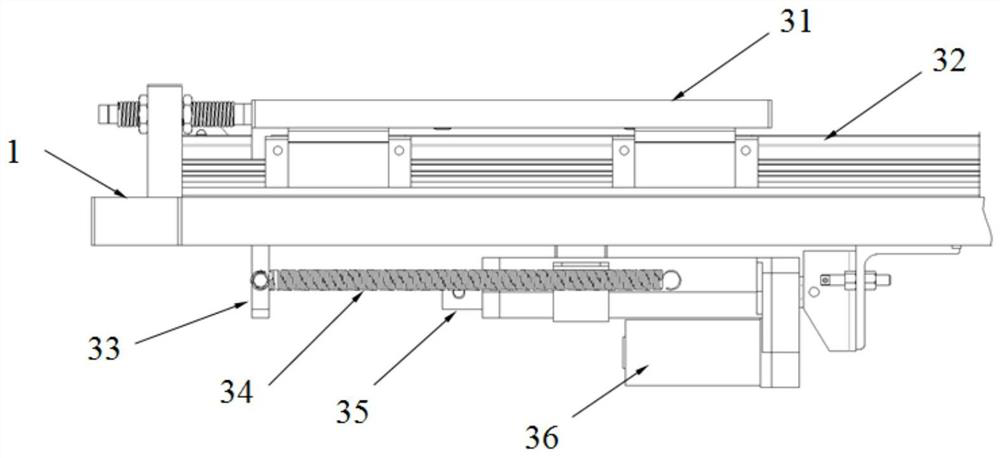

[0024] like figure 1 As shown, the present invention comprises a working platform 1, the left and right sides of the working platform 1 are all slidably connected with a horizontal motion mechanism 3, and a cutting mechanism 2 is installed on the horizontal movement mechanism 3, and the cutting mechanisms 2 on both sides are mirror images, and the cutting mechanism 2 A sample clamping mechanism 4 and a waste collection frame 5 are provided at the midpoint of the horizontal centripetal movement. The cutting mechanism 2, the horizontal movement mechanism 3 and the sample clamping mechanism 4 are all controlled by the electrical system, and the electrical system performs program setting and one-key operation through the human-computer interaction interface.

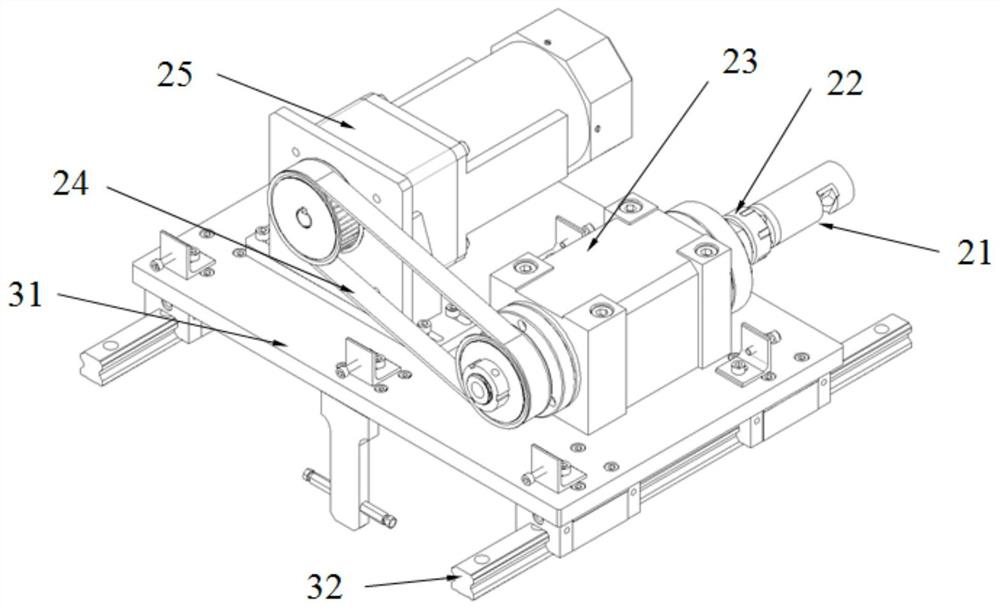

[0025] like figure 2 As shown, the cutting mechanism 2 includes a cutter 21, which is installed on the rotary power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com