Forecasting method for transmission intermediate shaft limit bearing capacity

A bearing capacity and intermediate shaft technology, applied in the direction of instruments, special data processing applications, electrical digital data processing, etc., can solve problems such as product development lag, inability to fully meet product development needs, difficulties, etc., to reduce the large deviation of calculation results problems, reducing human judgment time, and reducing product development costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0071] A method for predicting the ultimate bearing capacity of an intermediate shaft of a transmission, the method comprising the following steps:

[0072] Step 1, establishing a finite element model of the transmission intermediate shaft assembly;

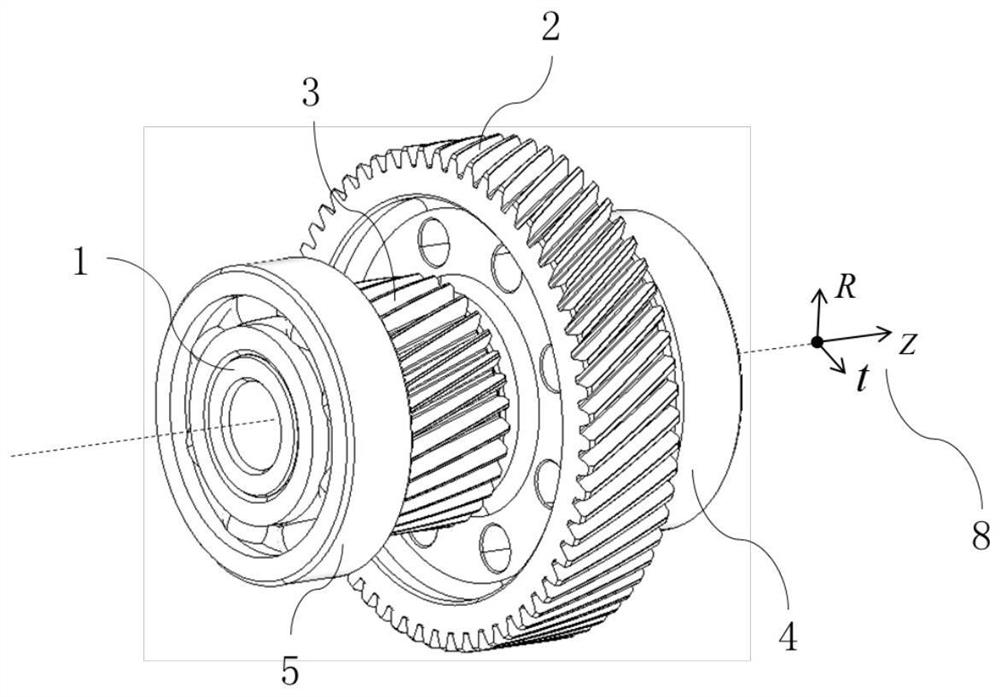

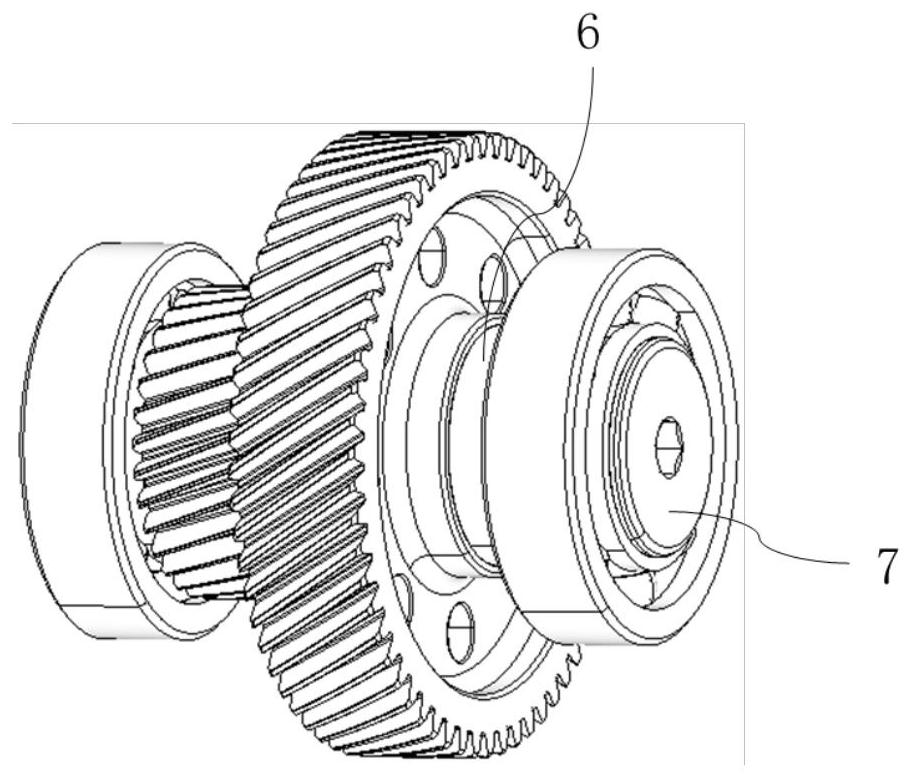

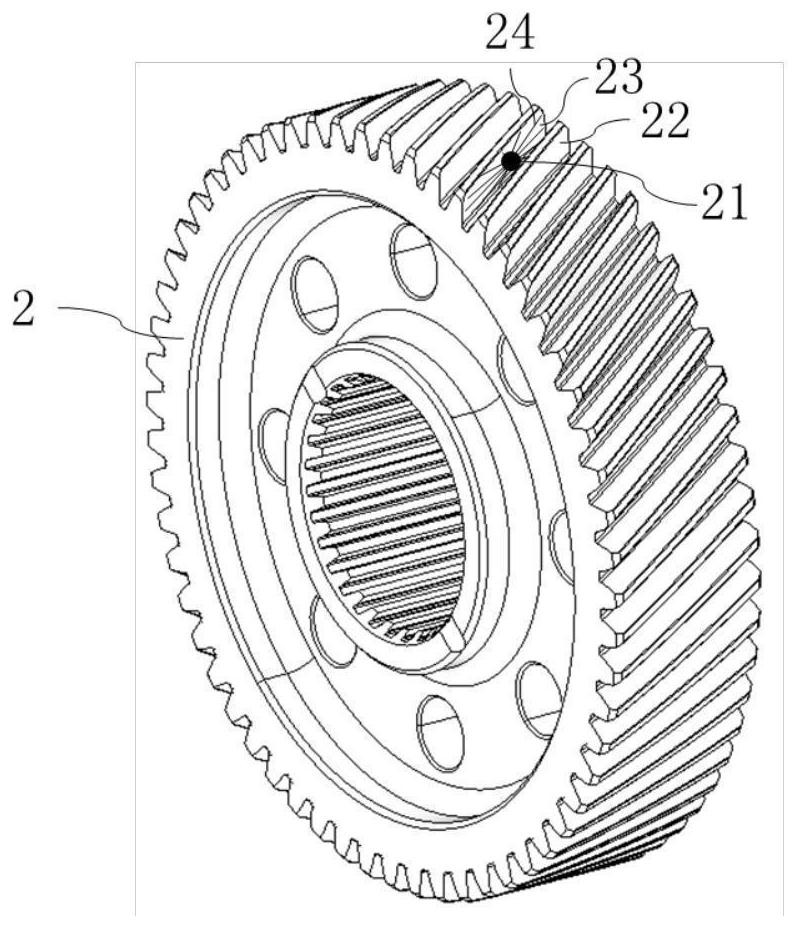

[0073] refer to figure 1 , figure 2 , mesh all the components of the transmission intermediate shaft assembly, including the intermediate shaft 1, the primary driven gear 2, the secondary driving gear 3, the front bearing 4, the rear bearing 5, the positioning sleeve 6, and the bolt 7, and then pass Define the contact relationship between the contacting parts to assemble them together.

[0074] Step 2. Define the material properties of the finite element model;

[0075] Define the elastic modulus E=210000MPa and Poisson’s ratio μ=0.3 of each finite element model of intermediate shaft 1, primary driven gear 2, secondary driving gear 3, front bearing 4, rear bearing 5, positioning sleeve 6, and bolt 7 , the front bearing 4, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com