Angle iron steel seal visual identification system and method assisted by linear lasers

A visual recognition and line laser technology, applied in the field of angle iron steel stamp visual recognition system, can solve the problems of different depths of dents, poor contrast, strong reflection, etc., and achieve the effect of improving the image quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

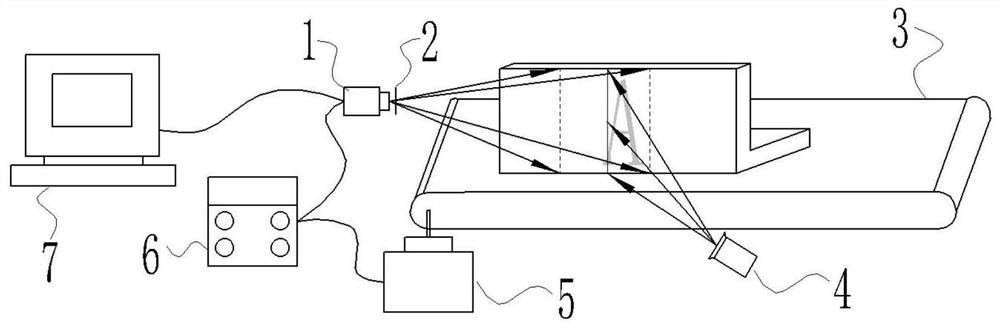

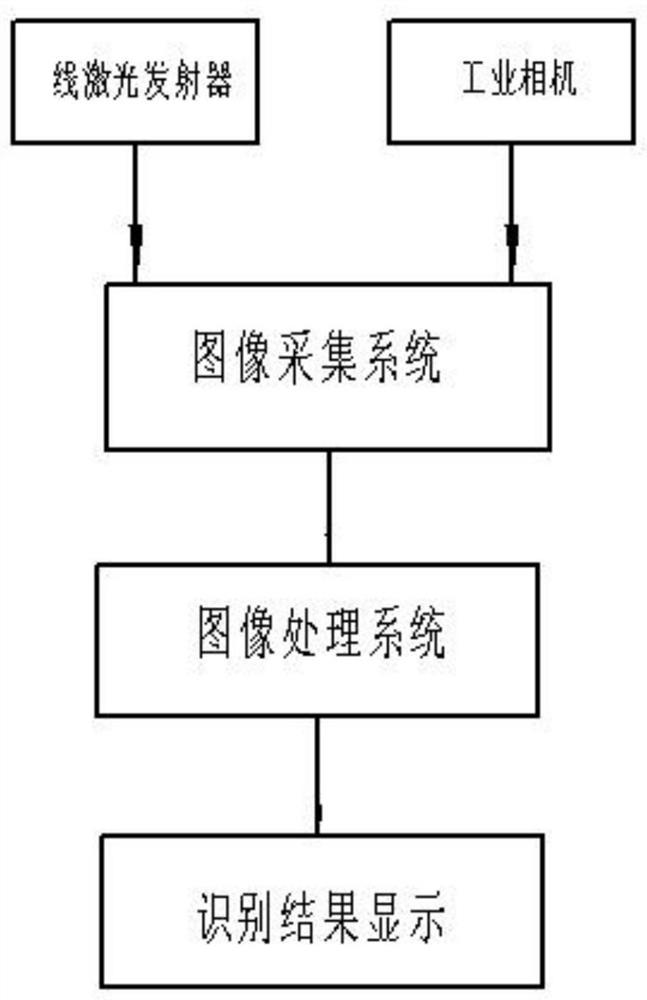

[0042] In this example, see figure 1 , a visual recognition system for angle steel seals that uses line lasers as an auxiliary, including an industrial camera 1, an optical filter 2, a conveyor belt 3, a line laser emitter 4, a motor 5, a controller 6 and an image processing system 7; the industrial The camera 1 is connected to the image processing system 7 through a data transmission interface; at the same time, the industrial camera 1, the motor 5 and the controller 6 are connected to each other to form a closed-loop system. N images are processed, and the line laser stripes in each image are extracted and recombined to form a new image, and then image processing is performed.

Embodiment 2

[0044] In this example, see figure 1 and figure 2 , a method for visual recognition of angle iron stencils assisted by a line laser, using the angle iron stencil visual recognition system described in Embodiment 1 to operate, comprising the following steps:

[0045] ① The angle iron moves at a certain speed and passes through the line laser emitted by the line laser transmitter;

[0046] ②The line laser is projected on the angle iron, and the industrial camera takes n images;

[0047] ③ The image processing system processes n images, extracts the line laser stripes in each image and recombines them into a new image;

[0048] ④ Through the recognition and calculation of the curved line laser image, the concave steel stamp on the angle iron is extracted.

Embodiment 3

[0050] This embodiment is basically the same as the above-mentioned embodiment, and the special features are:

[0051]In this embodiment, a method for visual recognition of steel seals on angle irons with the aid of line lasers, in step ②, when the angle irons pass through the line lasers, the n images to be captured by the industrial camera must include Each column on the iron, so there is a certain requirement for the shooting frequency of the industrial camera. Connect the motor of the conveyor belt to the controller. When the precision requirements are high, the output power of the motor can be reduced through the controller to slow down the moving speed of the angle iron. , and at the same time increase the shooting frequency of the industrial camera to effectively acquire the images of each column of the angle iron characters.

[0052] In this embodiment, in step ③, when processing n images containing line lasers, it is necessary to extract the laser lines of each image,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com