Belt conveyor post robot

A technology of robots and belt conveyors is applied in the field of robots to solve safety problems, avoid safety accidents and reduce labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

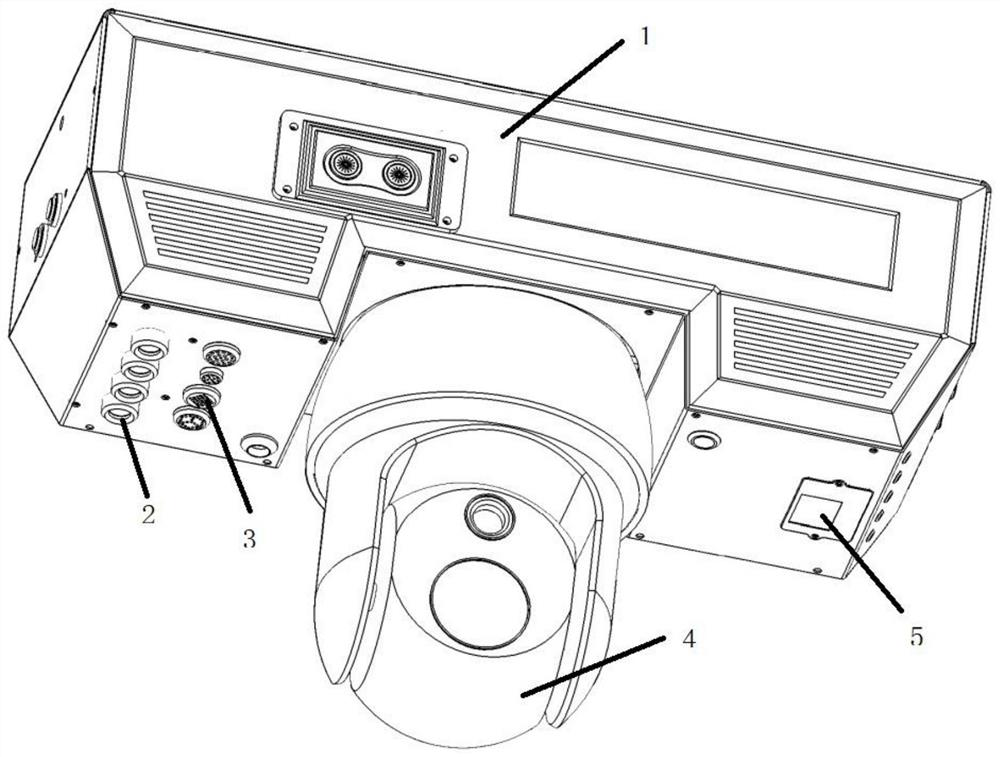

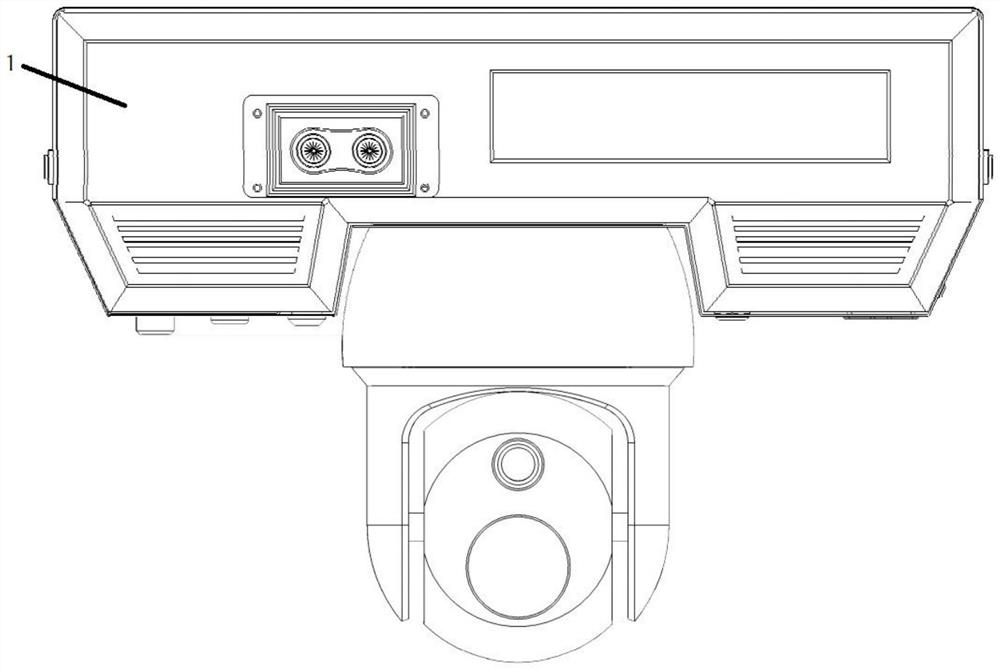

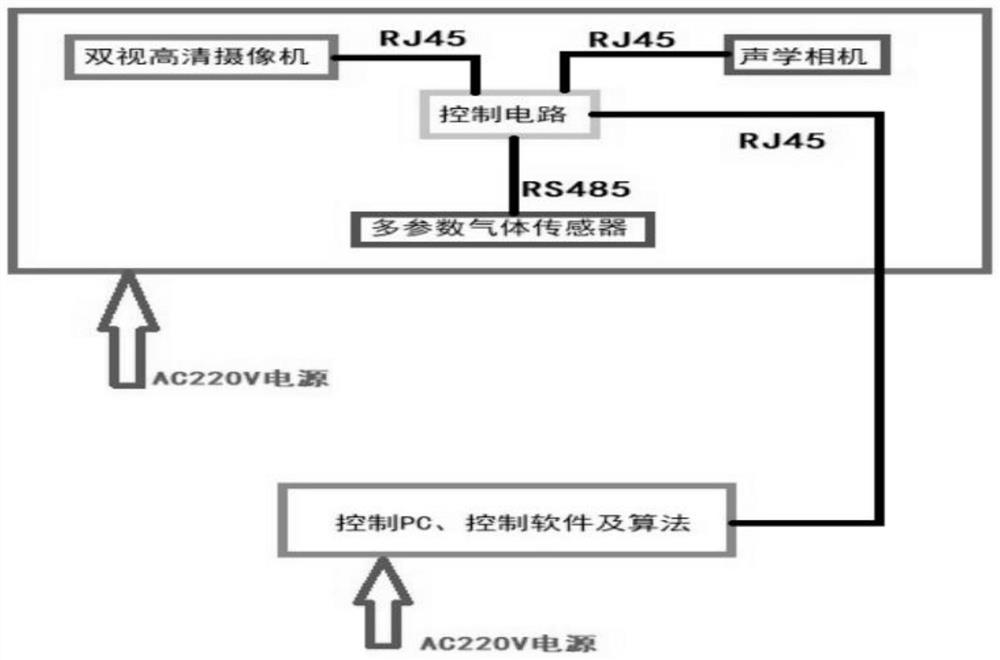

[0027] see Figure 1-3 As shown, the present invention relates to a belt conveyor post robot, which includes a robot housing 1, a remote control terminal, a dual-view high-definition camera 4, an acoustic camera 2, a multi-parameter gas sensor 3 and a control circuit board 5 , the center of the bottom of the robot housing 1 is recessed to form a mounting portion, and the bottom of the robot housing 1 is also provided with a second mounting position and a first mounting position, and the second mounting position and the first mounting position are distributed in On both sides of the installation part, the control circuit board 5 is arranged on the second installation position, the control circuit board 5 is integrated with a control circuit, and the control circuit is connected with the dual-view high-definition camera 4, the acoustic camera 2, The multi-parameter gas sensor 3 is connected; where,

[0028] The dual-view high-definition camera 4 is arranged on the installation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com