Man-machine engineering mechanical arm for rehabilitation training

An ergonomic, robotic arm technology, applied in passive exercise equipment, physical therapy and other directions, can solve the problems of inconvenience, patient safety, and inability to achieve flexible control, and achieve the effect of ease of use and burden reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

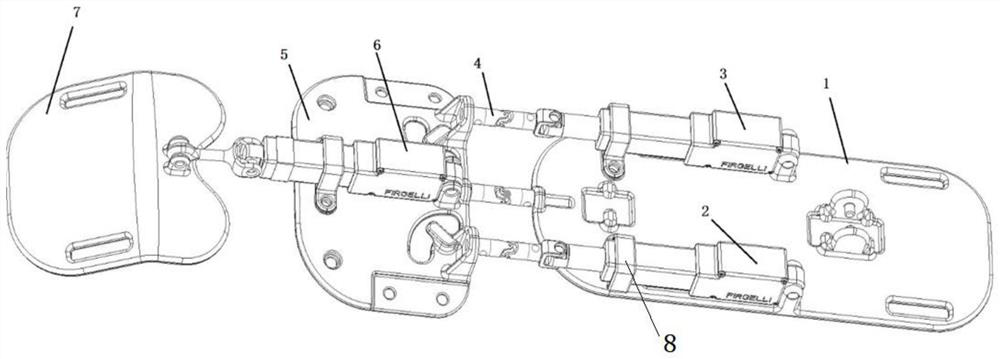

[0022] An ergonomic mechanical arm for rehabilitation training, including a forearm board 1, a first linear actuator A2, a second linear actuator B3, a universal joint mechanism 4, a palm board 5, a third linear actuator C6 and fingers plate 7.

[0023] The first linear actuator A2 and the second linear actuator B3 are arranged in parallel, and the ends of the two actuators are floatingly connected to the ear seat on the forearm plate 1 through pins; the U-shaped limit 8 is located on the actuators A and B , the middle part of C, and there is a gap between the actuator to limit the large-scale rotation of the mechanism and ensure safety. The other ends of the first linear actuator A2 and the second linear actuator B3 pass through the universal joint structure 4 and the palm plate 5 respectively. The ear sockets are connected; the third linear actuator C6 is located at the symmetrical center of the palm plate 5, and the end is connected to the forearm plate 1 through the third ...

Embodiment 2

[0026] The composition of this mechanical arm is as follows figure 1 As shown, it includes a linkage mechanism operated by three linear actuators to facilitate hand, wrist and forearm exercises. During use, the soft wrist strap is worn on the patient's forearm through the two slots at the rear of the forearm board 1. The palm board 5 is located at the back of the patient's hand. The forearm board 1 is floatingly connected with the palm board 5 through the universal joint mechanism 4. Through the groove on the finger plate 7, it is connected with the patient's finger.

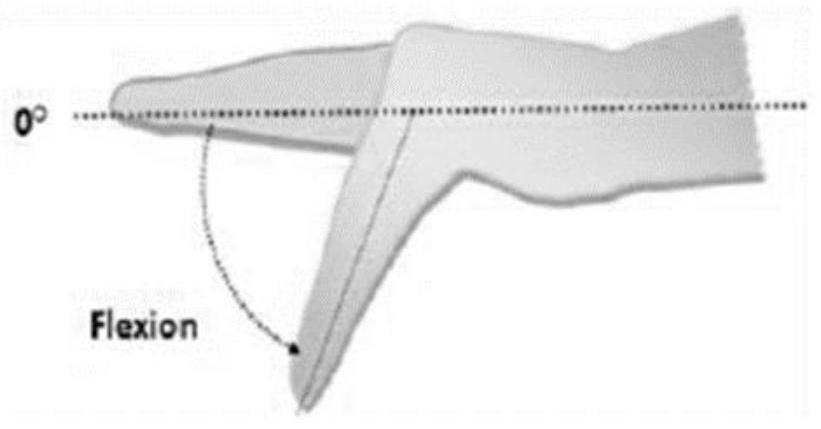

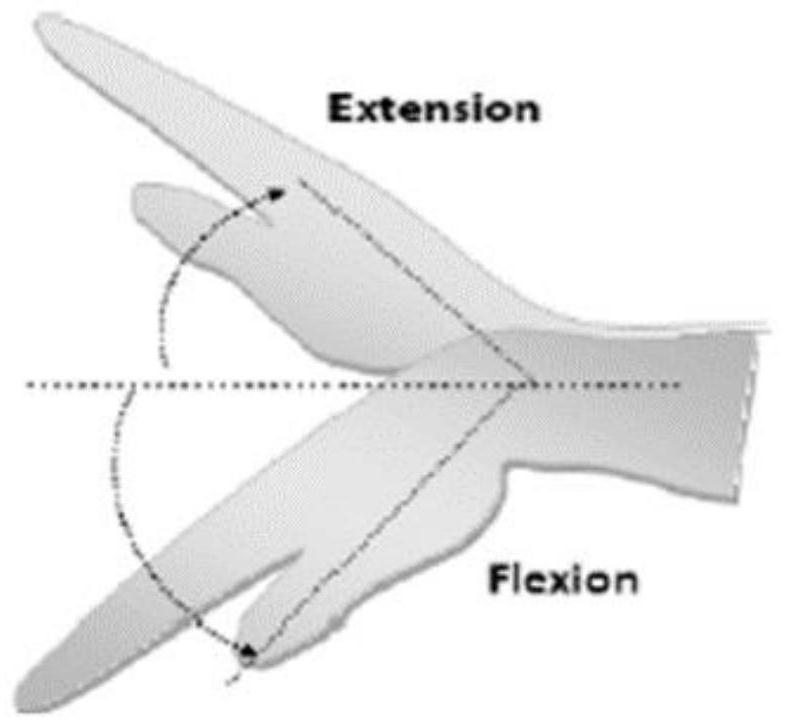

[0027] Two linear actuators on the forearm board 1 assist the wrist to realize the flexion-extension movement and flexion-ulnar deviation movement. When the linear actuators 1 and 2 are fully extended or half extended, the flexion-extension movement of the wrist is realized, such as Figure 2b As shown; when one of the linear actuators is fully extended and the other linear actuator is fully contracted, the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com