Method for controlling thickness stability of aluminum strip of cold-rolled 3104 alloy zip-top can

A control method and can technology, applied in rolling mill control devices, metal rolling, metal rolling, etc., can solve problems such as reducing product quality risks, rolling mill thickness fluctuations cannot be found in time, etc. The effect of stable quality and product quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

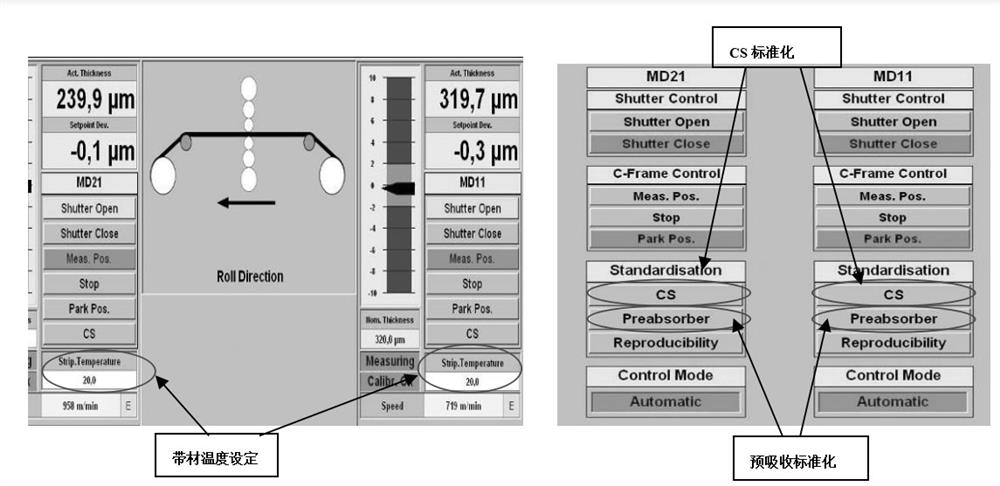

[0068] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0069] Please refer to figure 1 , the invention provides a method for controlling the thickness stability of a cold-rolled 3104 alloy pop can aluminum strip, comprising the following steps:

[0070] Step S1: construct 3104 alloy pop can standard sample;

[0071] Step S11: select pop can product 3104 alloy coil;

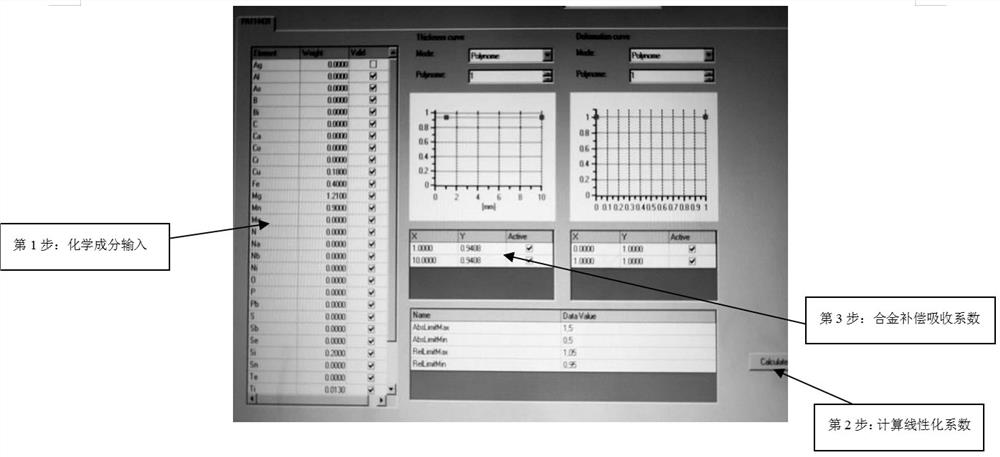

[0072] In this embodiment, preferably, the composition mass fraction % is: Si: 0.13-0.28, Fe; 0.32-0.48Cu: 0.12-0.25; Mn: 0.78-0.95, Mg: 1.1-1.35%; Cr<0.02; Zn<0.09; Ti<0.02. The chemical composition of the collected standard sample should be close to the median value of the 3104 chemical composition, that is, the average value of the upper and lower limits of each chemical element.

[0073] Step S12: Sample specification and testing method: The window of the launch head of the thickness gauge is 50mm, and the standard sample size (length*w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com