A special boring machine for multifunctional mechanical processing

A mechanical processing and multi-functional technology, applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of inconvenient left and right movement, inconvenient overall hoisting work of lighting equipment, inconvenient blocking work, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

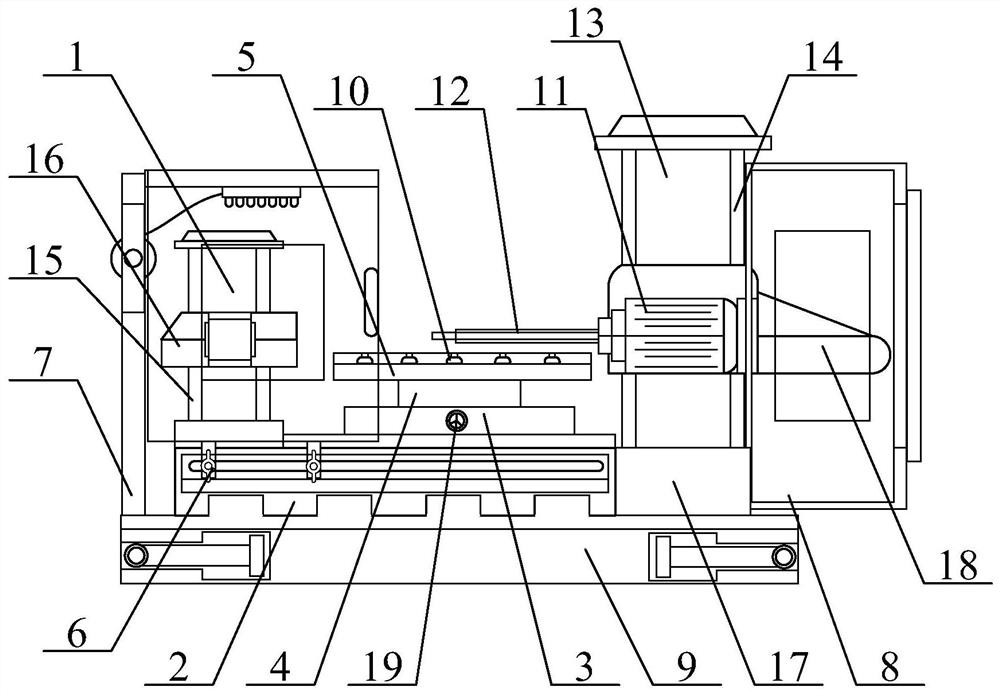

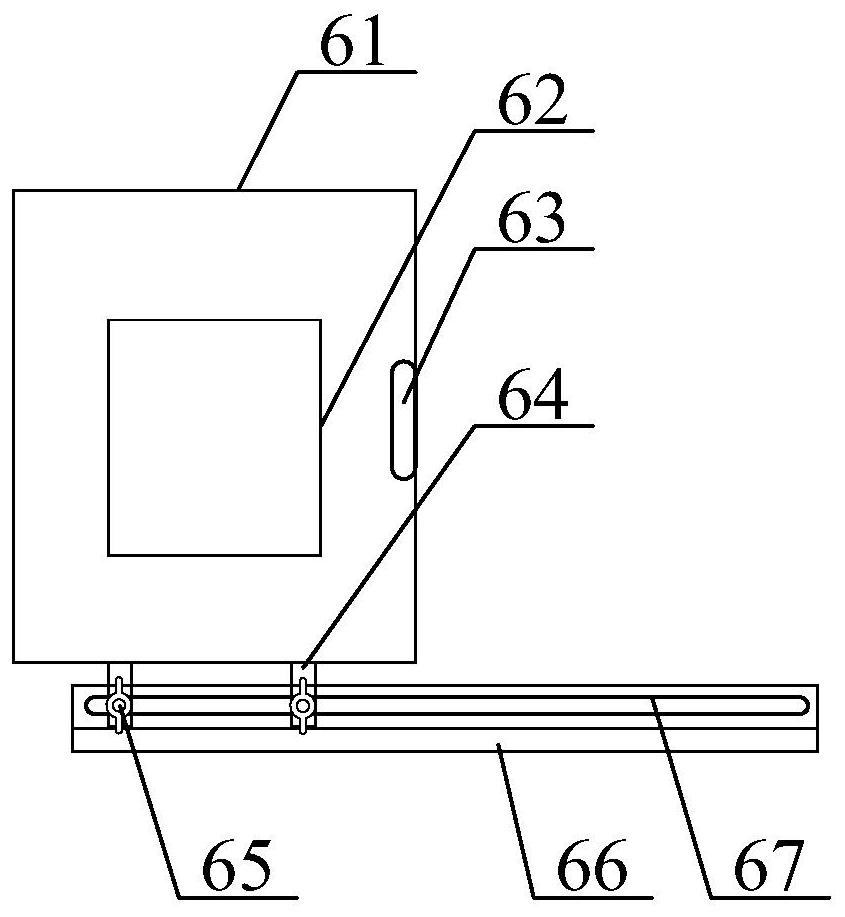

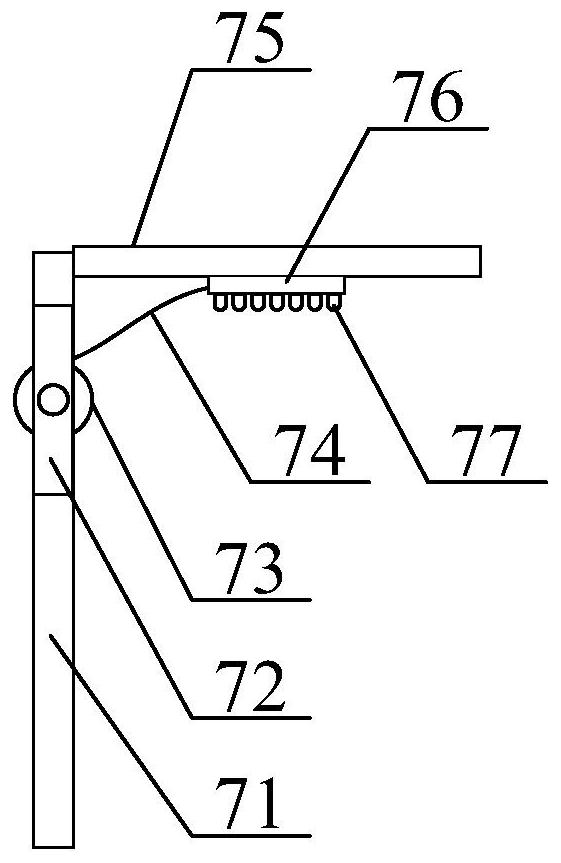

[0035] The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 And attached figure 2As shown, a multifunctional boring machine dedicated to mechanical processing includes a rear column 1, a boring machine bed 2, a working base 3, a turntable 4, a workbench 5, a sliding and locking cover structure 6, and a retractable and absorbing lighting seat Structure 7, Observable protective maintenance cover structure 8, retractable lifting seat structure 9, faceplate 10, motor 11, boring shaft body 12, front column 13, first guide rail 14, second guide rail 15, tailstock 16, connecting seat 17. Boring shaft rear seat 18 and control valve 19. The rear column 1 is bolted to the left side of the upper end of the boring machine bed 2; the working base 3 is bolted to the middle position of the upper end of the boring machine bed 2; The workbench 5 is set in rotational connection with the work base 3 through the turntable 4; the slida...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com