T-mold oil fume removal method of extruder

A technology of extruder and oil fume, which is applied in the field of extruder T-die oil fume removal, can solve the problems of polluting T-die touch head, reducing production efficiency, and easily dripping polluted products, so as to achieve the effect of improving production efficiency and production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is further elaborated below by specific embodiment:

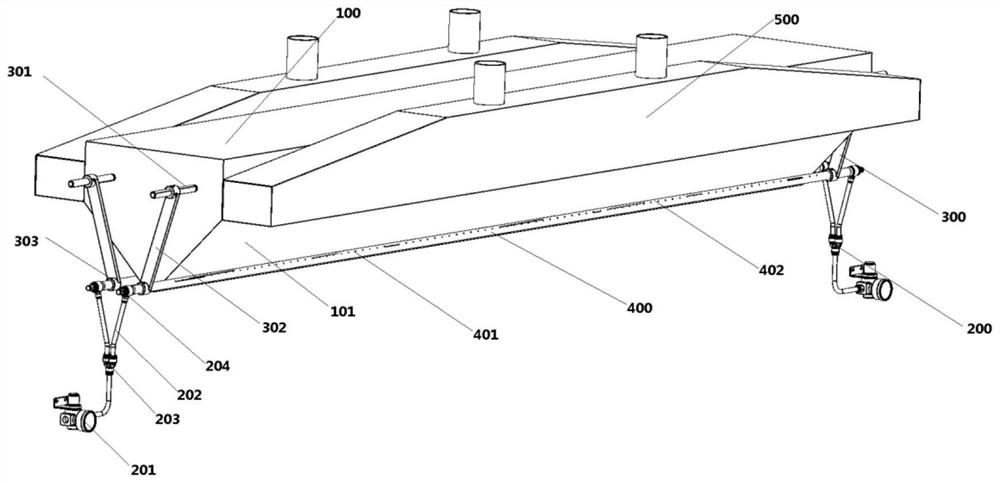

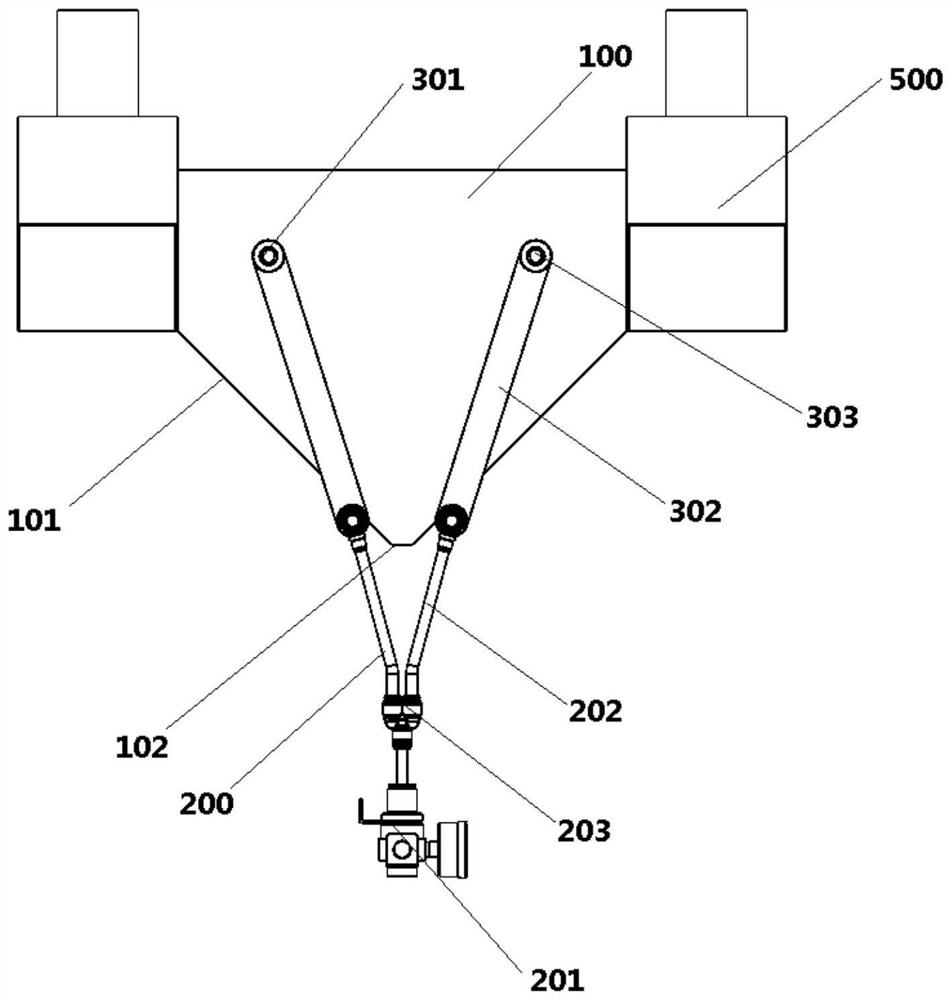

[0018] figure 1 An extruder is shown, including a T-die 100 , an air inlet device 200 , a fixing bracket 300 , a blow pipe 400 and a fume hood 500 .

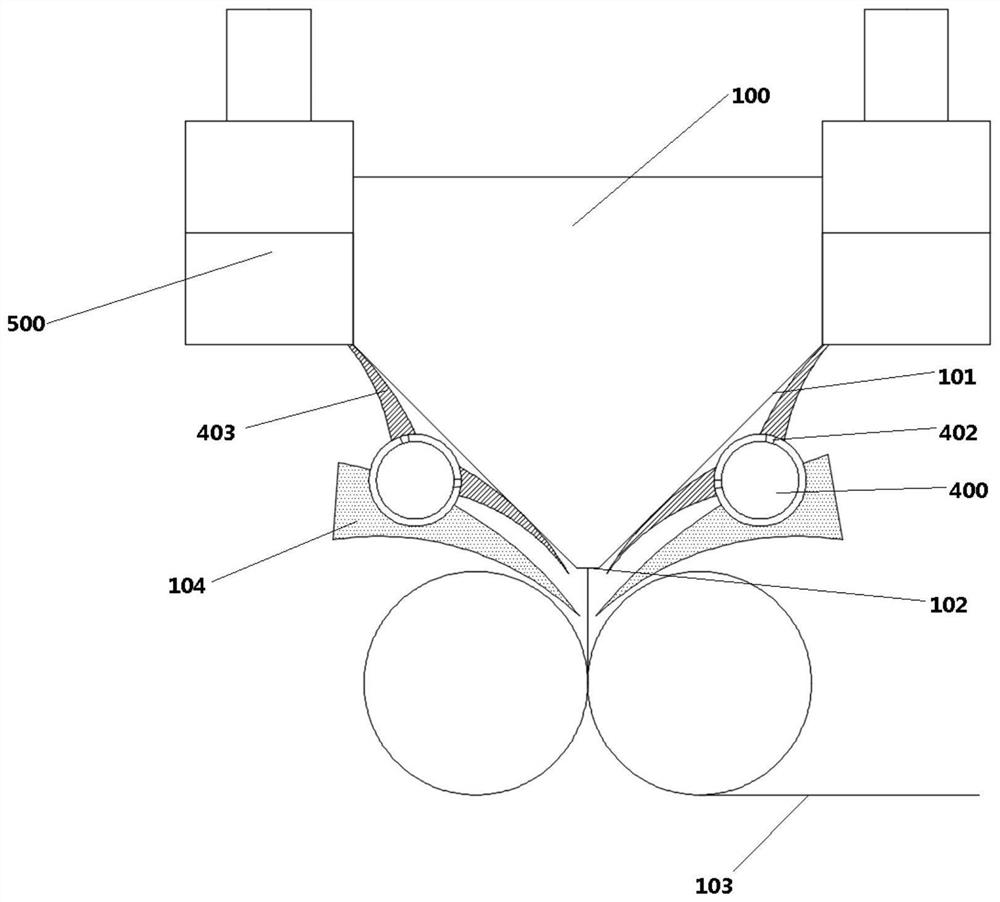

[0019] combine figure 1 and figure 2 , the T-die 100 is elongated, the upper half of its two sides is a vertical plane, the lower half is a slope 101 extending obliquely towards the middle of the bottom, and the middle of the bottom has a die opening 102 for discharging .

[0020] combine figure 1 and image 3 There are two oil fume hoods 500, which are arranged close to the upper half of the two sides of the T-die 100 respectively. The oil fume hoods 500 are connected with exhaust fans and can be used to absorb the oil fume 104 produced in the extrusion process.

[0021] combine figure 1 and figure 2 , a total of two blowing pipes 400 are located on the slopes 101 on both sides of the T-die 100, and the blowing pipes 400 are fixed by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com