Feeding and arranging device for red dates

An arranging device and jujube technology are applied in the directions of transportation and packaging, loading/unloading, conveyor objects, etc., which can solve the problems of increased labor costs, impurities that cannot be screened out, and low accuracy of jujube grading, so as to avoid manual participation and improve Work efficiency, the effect of ensuring continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

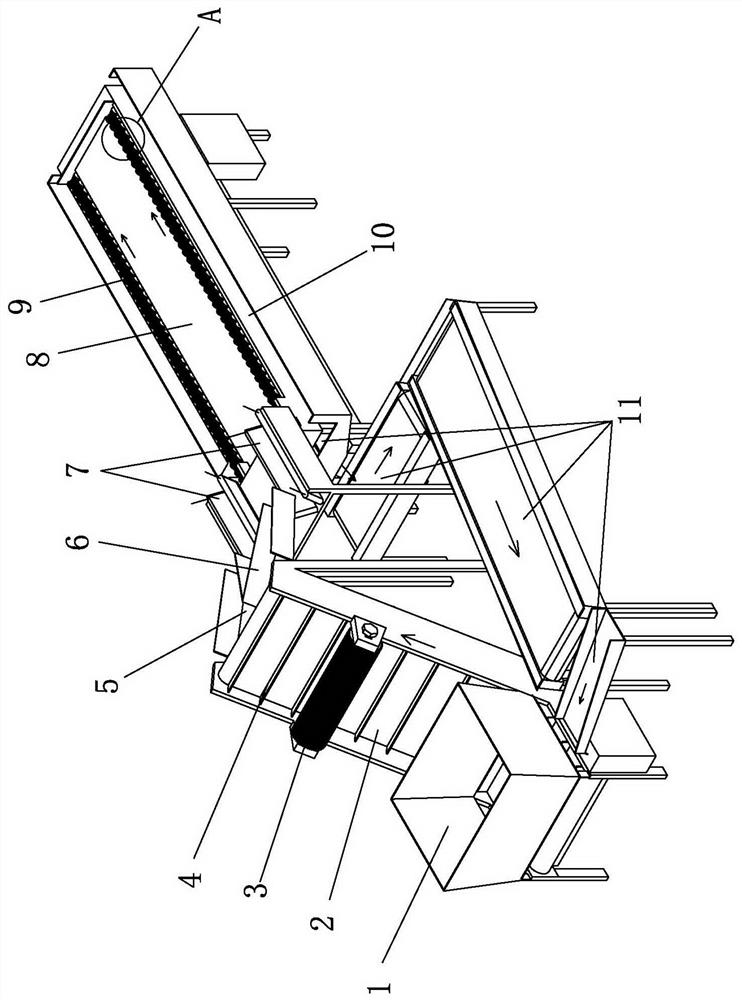

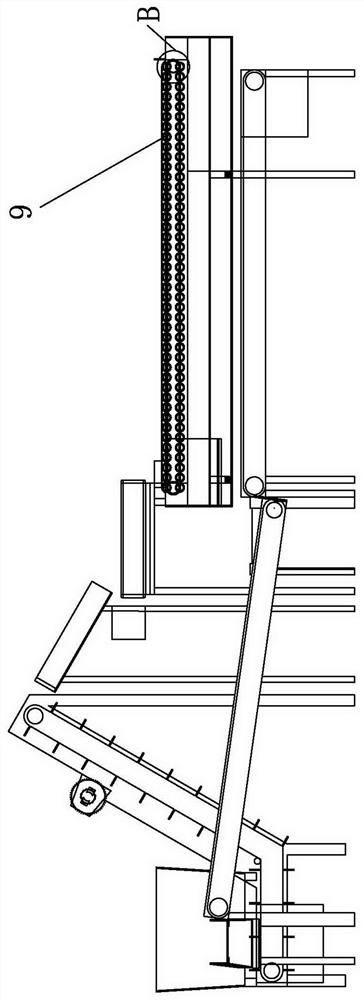

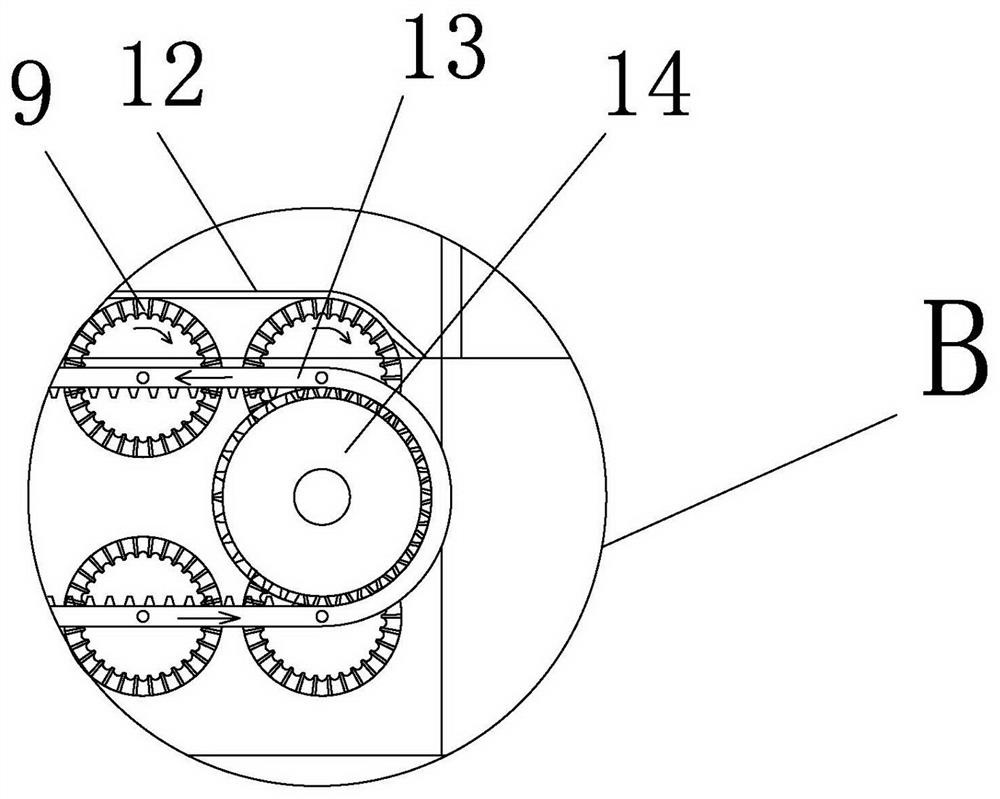

[0011] A device for feeding and arranging red dates, such as figure 1 , figure 2 , image 3 , Figure 4 As shown, including the frame and the motor, belt, and chain transmission mechanism installed on the frame, these traditional mechanical transmission mechanisms belong to the existing technology, and ordinary technicians familiar with the conveyor structure can fully understand the specific structure and work. The principle is not repeated here. The front of the frame is equipped with a hopper 1 and a scraper feeder 2. The upper part of the scraper feeder 2 is provided with a shaping drum 3 close to the feeder scraper 4 at a lateral interval. The shaping drum 3 can lift the scraper 4 The red dates that have been raised are sorted out to eliminate the excessive accumulation of red dates and make up for the depressions of red dates. A hopper 5 is arranged obliquely on the frame behind the upper discharge port of the feeder 2. The upper mouth of the hopper 5 is wide and the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com