Temporary plugging object and temporary plugging object dispenser

A dispenser and core technology, which is applied to drilling compositions, chemical instruments and methods, wellbore/well components, etc., can solve the problems of low plugging success rate, production shutdown, large injection volume, etc., and meet the plugging requirements The effect of process technology requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

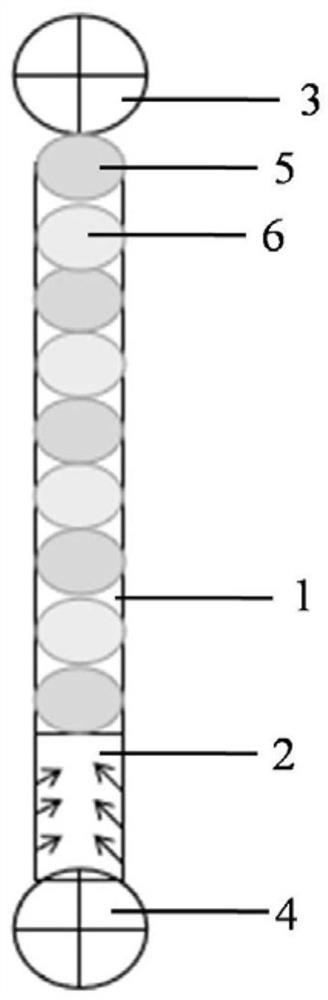

[0065] Preparation of knot temporary plug

[0066] The wall thickness L of the simulated wellbore is 70 mm, the diameter r of the simulated plugged perforation is 30 mm, and the depth n of the core of the temporary plugging material embedded in the perforation is 5 mm. The maximum cross-sectional diameter R of the inner core of the temporary blockage is 30mm.

[0067] The acrylic cloth-like braid with a length of 10 cm and a width of 5 cm is used to make a spherical knot inner core with a diameter of 30 mm by cross-knotting.

[0068] After mixing 54g of 400-500 mesh nano-silica powder and 6g of 10wt% polyvinyl alcohol aqueous solution and stirring evenly, manually wrapping the outside of the inner core of the knot, then filling it into a spherical mold with an inner diameter of 5cm, and compacting it at 90 ℃ drying for 2 hours to obtain a semi-finished temporary plug wrapped with a wrapping layer.

[0069] After taking out the semi-finished temporary blockage, spray ammonium...

Embodiment 2

[0071] Preparation of knot temporary plug

[0072] The wall thickness L of the simulated wellbore is 70 mm, the diameter r of the simulated plugged perforation is 30 mm, and the depth n of the core of the temporary plugging material embedded in the perforation is 7 mm. According to the formula R=(L-n) / L*r, the maximum cross-sectional diameter of the inner core of the temporary blockage is R=27mm.

[0073] The acrylic fibers with a length of 20 m and an average diameter of 0.06 cm are used to make a spherical knot core with a diameter of 27 mm by cross-knotting.

[0074] After mixing 76g of 300-400 mesh nano-silica powder and 4g of 5% polyvinyl alcohol aqueous solution and stirring evenly, manually wrapping the outer core of the knot, then filling it into a spherical mold with an inner diameter of 5cm, compacting and forming it at 90 ℃ drying for 2 hours to obtain a semi-finished temporary plug wrapped with a wrapping layer.

[0075] After taking out the semi-finished tempora...

Embodiment 3

[0077] Preparation of knot temporary plug

[0078] The wall thickness L of the simulated wellbore is 50 mm, the diameter r of the simulated plugged perforation is 20 mm, and the depth n of the core of the temporary plugging material embedded in the perforation is 10 mm. According to the formula R=(L-n) / L*r, the maximum cross-sectional diameter of the inner core of the temporary blockage is R=16mm.

[0079] Spandex fibers with a length of 50 m and an average diameter of 0.03 cm were used to make a spherical knot core with a diameter of 16 mm by cross-knotting.

[0080] Use 95g of ultra-fine calcium chloride powder of 300-500 mesh and 5g of aqueous solution containing 1% polyvinyl alcohol to stir evenly, then wrap it manually outside the inner core of the knot, then fill it into a spherical mold with an inner diameter of 5cm, compact it and place it at 90°C Dry for 2 hours to obtain a semi-finished temporary plug wrapped with a wrapping layer.

[0081] After taking out the sem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com