A kind of wall tile laying equipment

A technology of paving and equipment, applied in construction, building structure, etc., can solve the problems of inability to meet operation requirements, high chassis positioning frequency, and small coverage of paving, so as to expand the coverage of operations, improve operational capabilities, and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

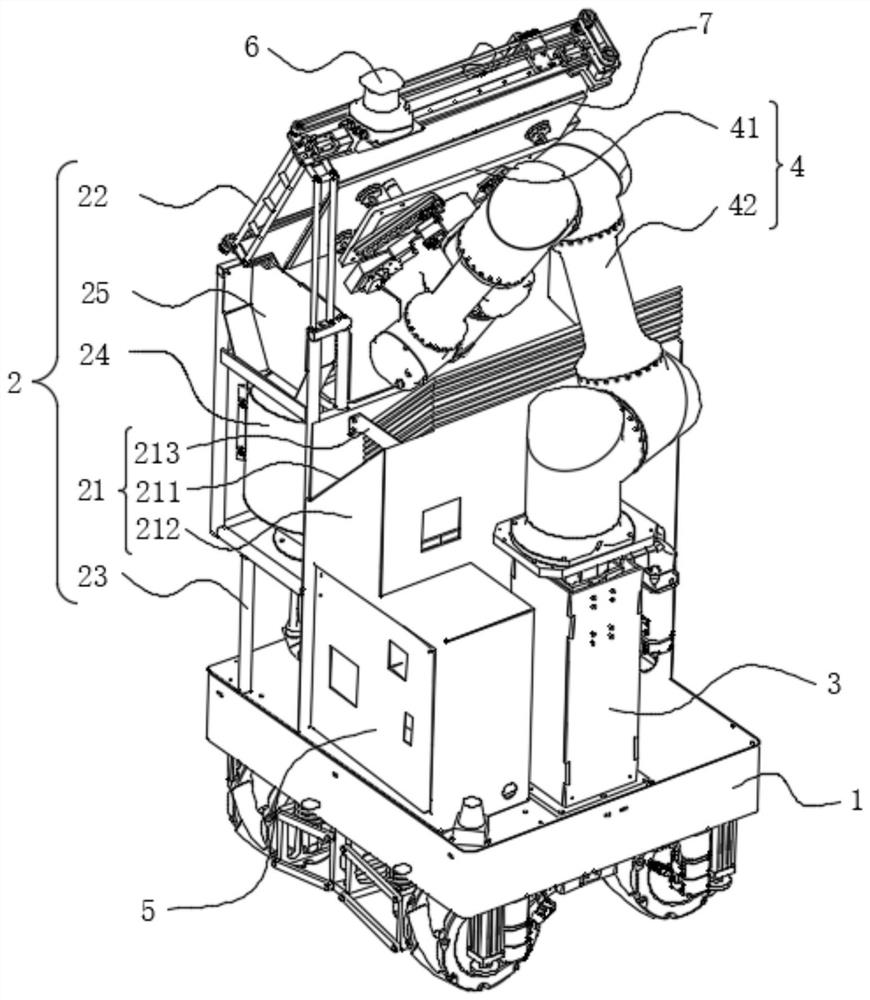

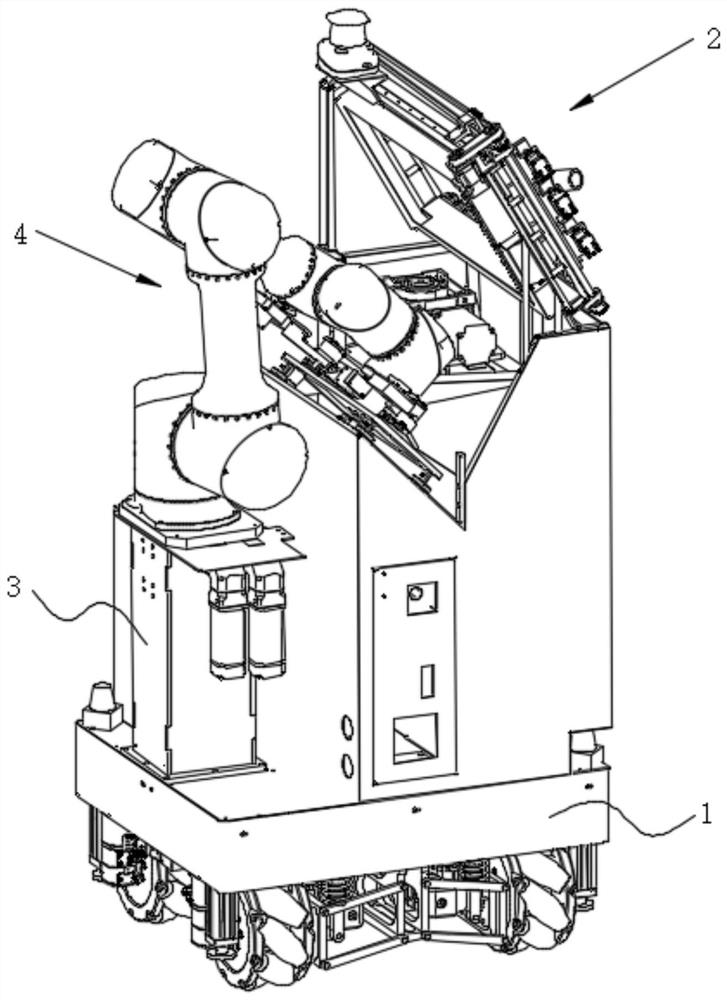

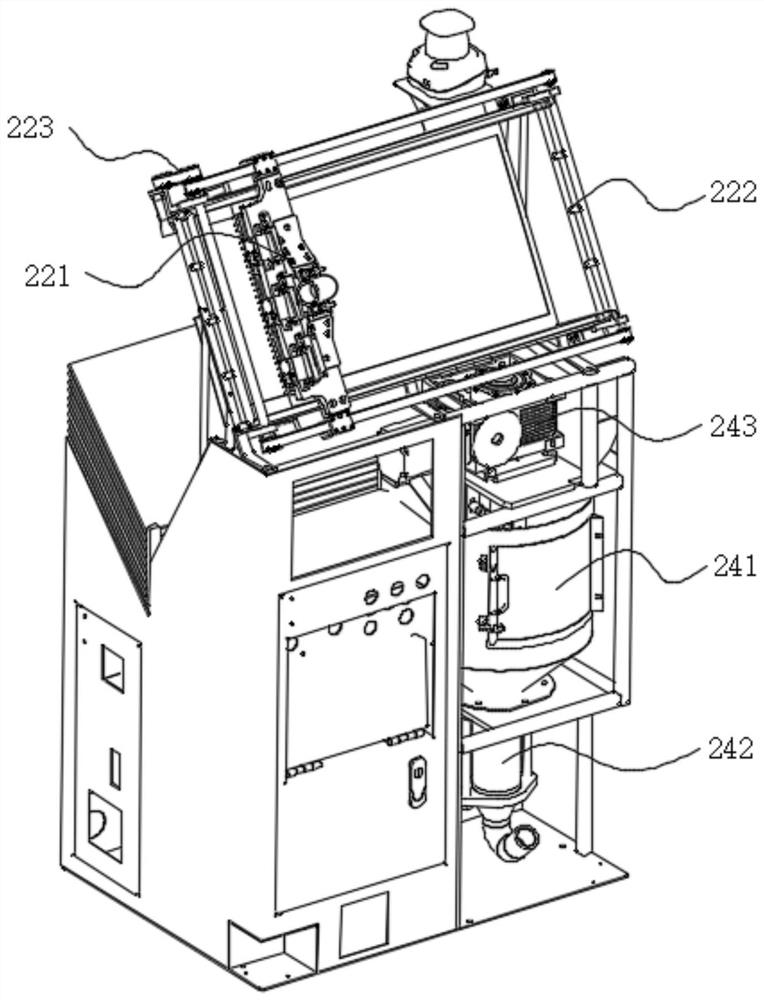

[0081] A wall tile laying equipment, such as figure 1 with figure 2 As shown, it includes a mobile chassis 1, a feeding device 2, a lifting device 3 and a paving robot. The feeding device 2 is installed on one end of the mobile chassis 1 to provide tiles 7 and bonding materials; the lifting device 3 is installed on the mobile chassis. The other end of 1; the paving manipulator is installed on the top of the lifting device 3, the left and right sides of the paving manipulator and the side far away from the feeding device 2 cooperate to form an empty activity area, and the paving manipulator can be driven up and down by the lifting device 3 Move and obtain the tiles 7 coated with bonding material from the feeding device 2, and can move in the vacant activity area and lay the tiles 7 on different target working surfaces.

[0082]Specifically, by arranging the feeding device 2 and the lifting device 3 at opposite ends of the mobile chassis 1, and setting the paving manipulator o...

Embodiment 2

[0105] The difference between this embodiment and Embodiment 1 is:

[0106] The inclined bearing plate 211 is connected to the mobile chassis 1 in a swinging manner, and is used to adjust the angle between the inclined bearing plate 211 and the horizontal plane; Specifically, adjusting the included angle according to different sizes and specifications of the ceramic tiles 7 can make the brick feeding mechanism 21 and the applying mechanism 22 meet the use requirements of tiles 7 of more different specifications. Further, when the size of the tile 7 is relatively small, the angle between the inclined bearing plate 211 and the horizontal plane can be reduced to make the inclined bearing plate 211 more gentle, thereby making the placement of the ceramic tile 7 more stable. The distance between the applicator 221 and the horizontal plane can also be adjusted The included angle is reduced so that the bonding material can be applied on the tile 7 more reliably, and the bonding mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com