In-situ grouting repairing method for cracking of loess cave dwellings in former sites

A repair method and grouting technology, applied in building maintenance, construction, building construction and other directions, can solve the problems of insufficient stability of gel time adjustment, small controllable range, poor repair effect, etc., to achieve protection and repair effect, prolong preservation Time and construction convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

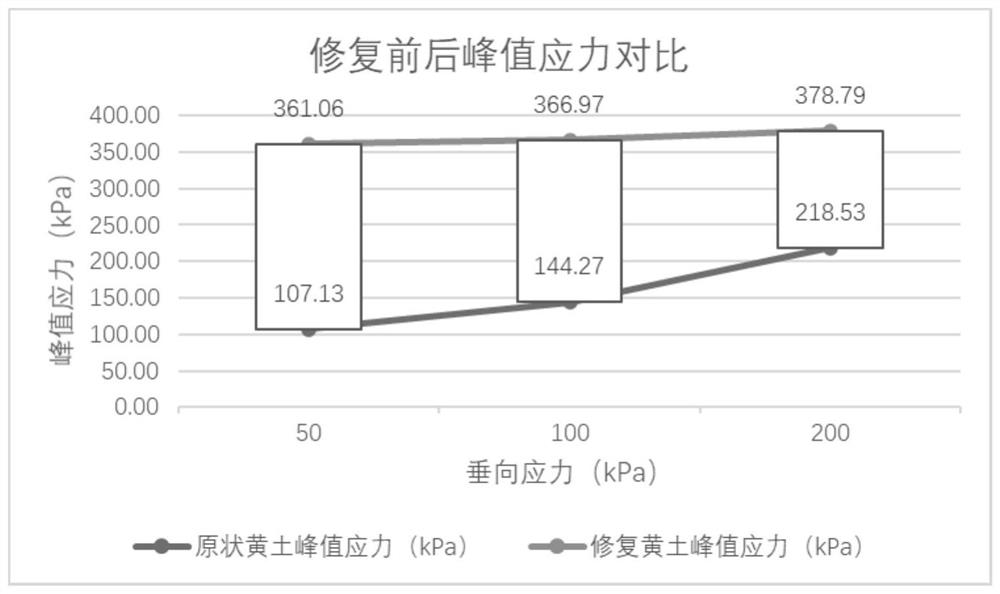

[0024] An in-situ grouting repair method for cracks in loess cave dwellings at the revolutionary site in Yan'an area. The repair method is divided into four parts: grout preparation, grouting repair, waterproof bedding, and restoration and greening:

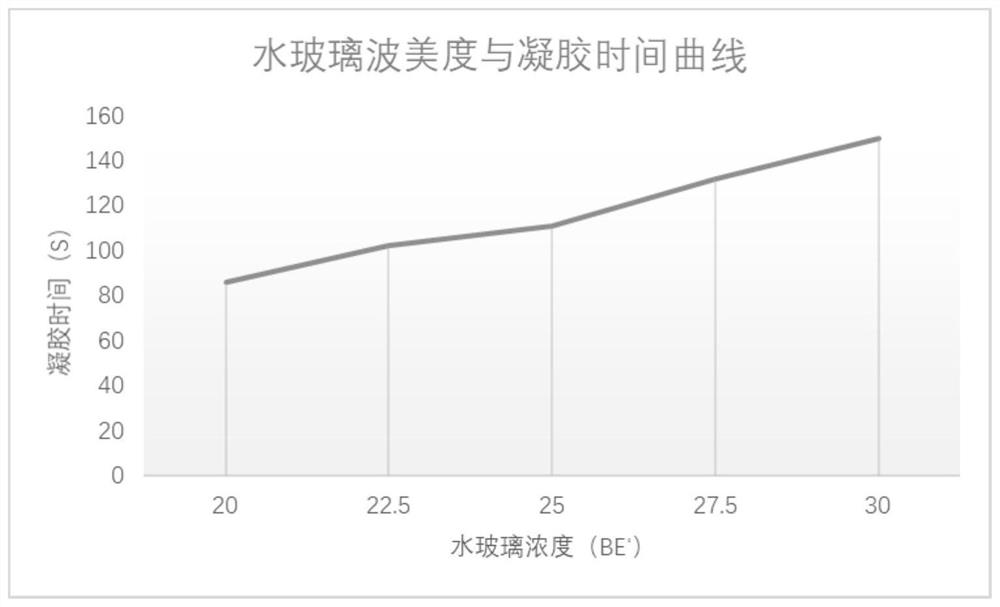

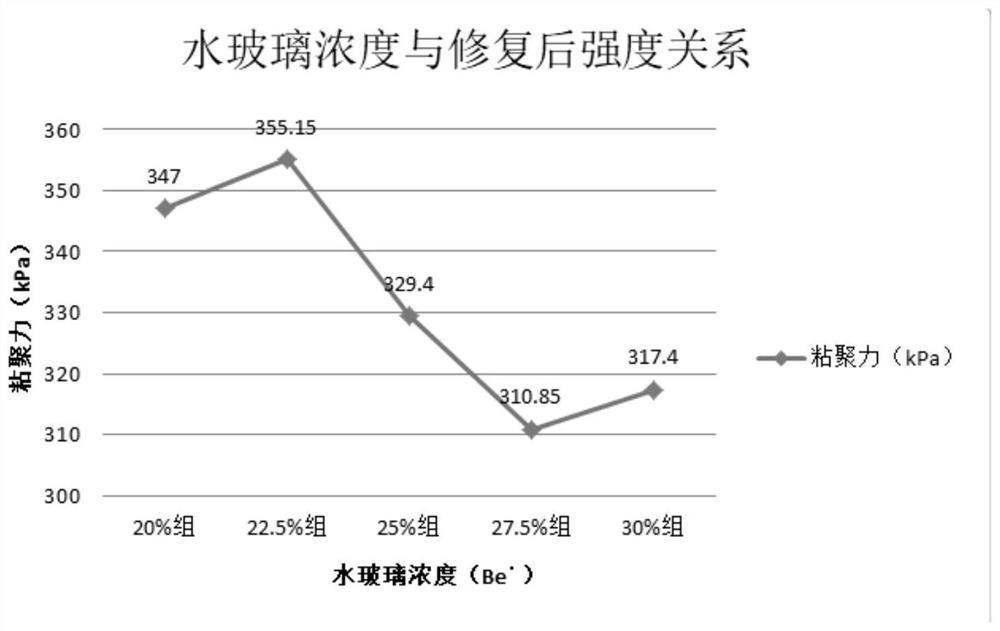

[0025] For the preparation of the slurry, liquid A is prepared with 800 mesh khaki superfine cement according to the water-cement ratio of 0.4 (that is, the quality of water is 40% of the cement weight), and fully stirred. Heat is released during mixing, and stirred until the solution returns to room temperature; liquid B uses sodium silicate solid particles and distilled water to prepare a water glass solution with a Baume degree of 22.5%; cement-water glass double slurry is A that will be cooled to room temperature Solution and B solution are thoroughly mixed and stirred.

[0026] For the above-mentioned grouting repair, grouting points should be arranged for cracks with a width of more than 8mm, and then the prepared double gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com