An ultra-thin heat pipe with gradient ordered pores porous capillary core and its manufacturing method

An ultra-thin heat pipe and capillary core technology, applied in indirect heat exchangers, heat exchange equipment, heat exchanger shells, etc., can solve the problems of small steam circulation space and weak capillary driving force, and increase the available space, capillary The effect of strong driving force and large circulation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

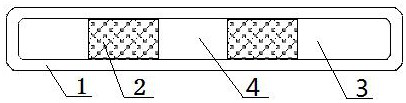

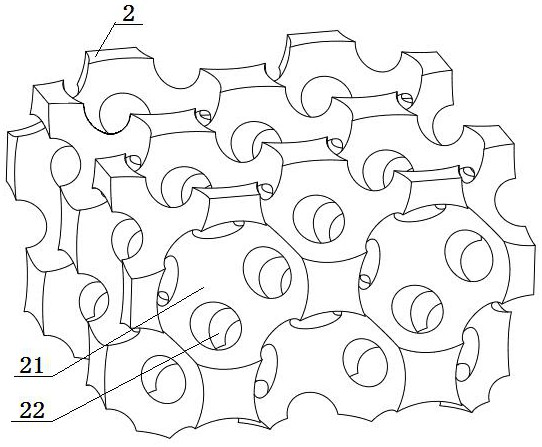

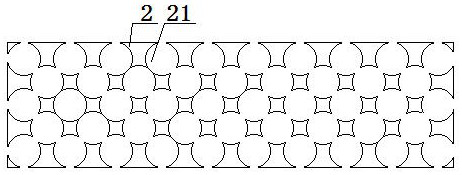

[0060] A gradient ordered aperture porous capillary core ultra-thin heat pipe, including a tubic body 1, a cross section a rectangular flat tube structure; the tubular body is provided with at least two housing axial arrangement The porous hair core 2, the porous capillary core 2 in the tubular body 1 separates a plurality of steam passages 3; the porous hair core 2 is a metal capillary core having a lot of pores inside, and the porous capillary core 2 is covered with sphere. A circular aperture 22 is formed at the phase of the hole 21, and the adjacent spherical hole 21 is formed; the spherical holes 21 in the porous capillary core 2 are all in the same diameter, and the single spherical hole 21 is passed through a circular aperture 22. Instead of the twelve spherical holes 21 adjacent; the spherical hole 21 has a diameter of 0.02 to 0.08 mm, and the thickness of the tubular body 1 is 0.26-6 mm, and the tube wall thickness of the tubular body is 0.06- 0.1 mm; the porous capillary...

Embodiment 2

[0067] Example 2 Example 1 is substantially the same, except that it:

[0068] The tubular body 1 is provided with a porous wick three axially disposed along the tubular body 2; the diameter of the spherical hole 2 filled the porous wick 21 by the middle to the top, bottom diameter is gradually reduced, the porous spherical hole 21 of the middle wick 2 is the same medium-diameter ball holes 24, the same small diameter ball holes 23 of the porous wick 2 and a spherical top 21 of the bottom of the hole, the ball holes 23 of small circular aperture 22 through its Medium eight ball holes adjacent four medium-sized spherical cavity 24 communicating, through holes 24 of the medium-sized ball 22 a circular aperture 24 in communication adjacent thereto; spherical diameter of the hole 21 is 0.02-0.08 mm, diameter 0.02 -0.04 mm between the holes 21 of small spherical ball holes 23, the diameter of the spherical bore 21 between 0.021-0.06 mm for medium-sized ball holes 24; thickness of the t...

Embodiment 3

[0070] Example 3 Example 1 is substantially the same, except that it:

[0071] The tubular body 1 is provided with a porous wick four axially disposed along the tubular body 2; 2 full bore diameter of the spherical porous wick 21 the shape of the upper layer to the lower order gradient, said orderly gradient of decreasing diameter from the upper layer to the lower layer or the upper layer to the diameter gradually increases from the lower layer; diameter of the spherical pores within the porous wick 2 is covered by the upper layer 21 is gradually reduced to a lower layer, the porous wick 2 spherical pores top layer 21 of the same diameter of large ball holes 25, the spherical pores of the porous wick 2 middle layer 21 of the same diameter of the medium-sized ball holes 24, the same diameter of the small ball holes 23 spherical pores of the porous wick 2 the bottom 21 of the , the upper end of the lower four large and medium-sized ball hole 25 through the ball holes 22 circular ape...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com