Bridge inhaul cable surface detection device

A bridge cable and surface detection technology, which is applied in the direction of measuring devices, optical testing of defects/defects, and material analysis through optical means, can solve problems such as potential safety hazards, scars, holes, and surface erosion, and achieve reliable detection results , Low equipment failure rate, simple transmission structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

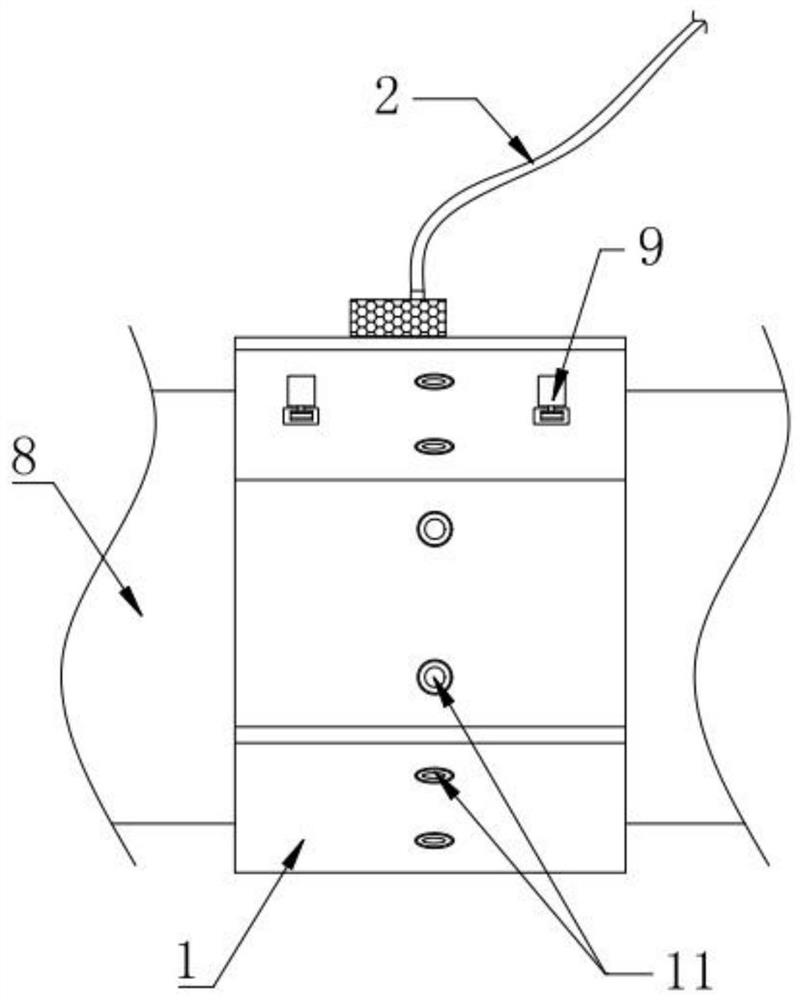

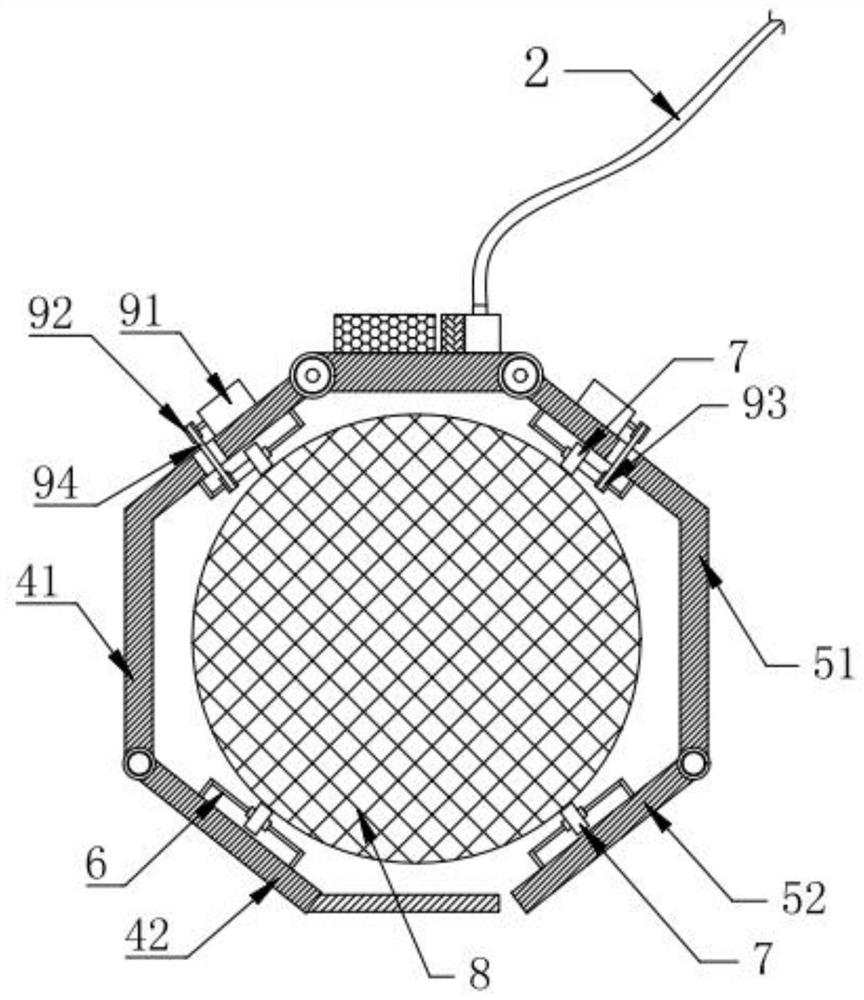

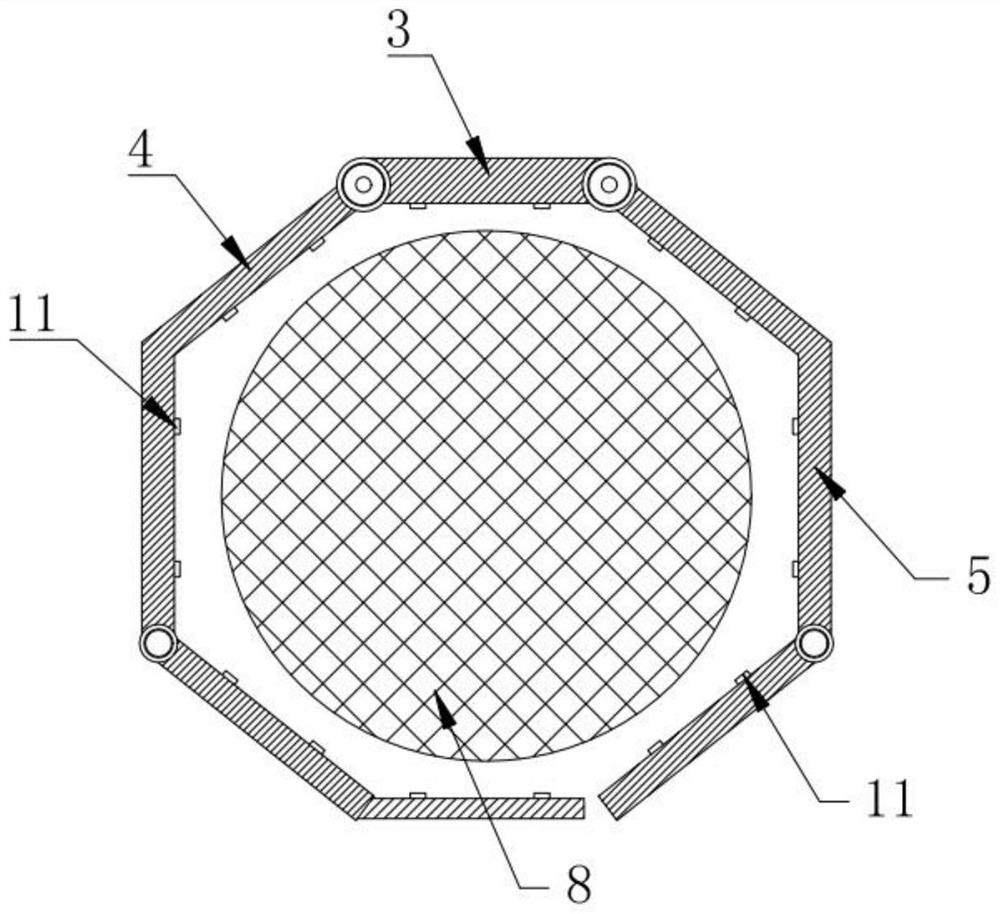

[0040] A bridge cable surface detection device, such as figure 1 , figure 2 and image 3 As shown, it includes a ring bracket 1, an image acquisition device 11, a driving device 9 and an anti-interference cable 2. The ring bracket 1 includes a mounting plate 3, a first hoop 4 and a second hoop 5, and the fixed end of the first hoop 4 It is rotatably connected to one end of the mounting plate 3, and the fixed end of the second hoop plate 5 is rotatably connected to the other end of the mounting plate 3. Both the inner side of the first hoop plate 4 and the inner side of the second hoop plate 5 are provided with support rods 6 , the support rod 6 is provided with a roller 7, and a plurality of rollers 7 are arranged along the circumferential direction of the ring support 1. When the ring support 1 is set on the bridge cable 8, the rollers 7 are in contact with the outer surface of the bridge cable 8. , the roller 7 is used to drive the ring support 1 to move along the length ...

Embodiment 2

[0065]According to the above method, sample I was prepared with the following barium titanate shielding layer 222 and carbon shielding layer 231 in the following weight fractions:

[0066] Components of the carbon shielding layer 231: 6 parts of graphite fiber, 1 part of carbon powder, 3 parts of epoxy resin, 0.2 part of dimethyl silicone oil, 0.15 part of polyphenylene sulfide, 0.07 part of phenolic resin, and 0.05 part of p-xylene.

[0067] The components of barium titanate shielding layer 222: 6 parts of PLA porous microspheres, 6 parts of barium titanate powder, 2 parts of epoxy resin, 0.3 parts of dimethyl silicone oil, 0.2 parts of polyphenylene sulfide, 0.08 parts of phenolic resin, 0.05 parts of xylene.

[0068] According to the above-mentioned method, sample II was prepared with the barium titanate shielding layer 222 and the carbon shielding layer 231 in the following weight fractions:

[0069] Components of the carbon shielding layer 231: 4 parts of graphite fiber,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com