Bio-organic fertilizer granulator

A bio-organic fertilizer and granulator technology, applied in dryers, mold extrusion granulation, lighting and heating equipment, etc., can solve the adverse effects of organic fertilizer molding, plate hole scaling, organic fertilizer easy to bond, etc. problem, to achieve good granulation effect and increase the service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

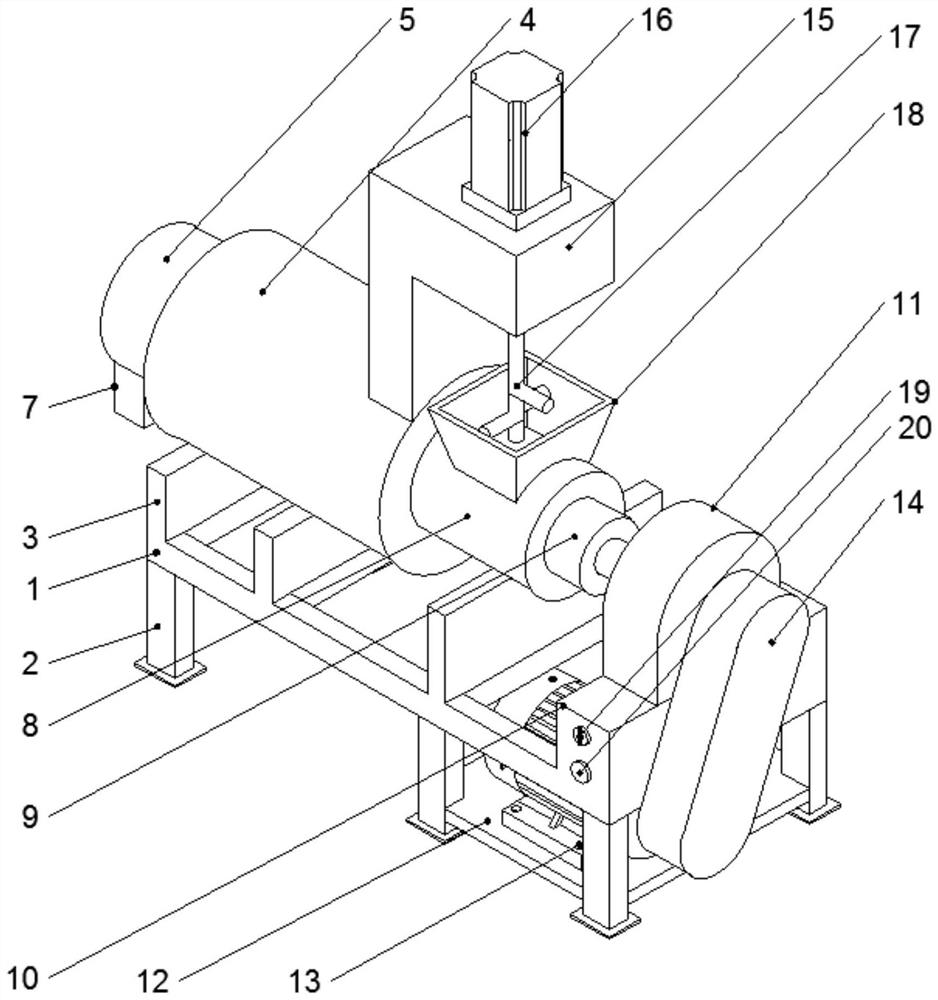

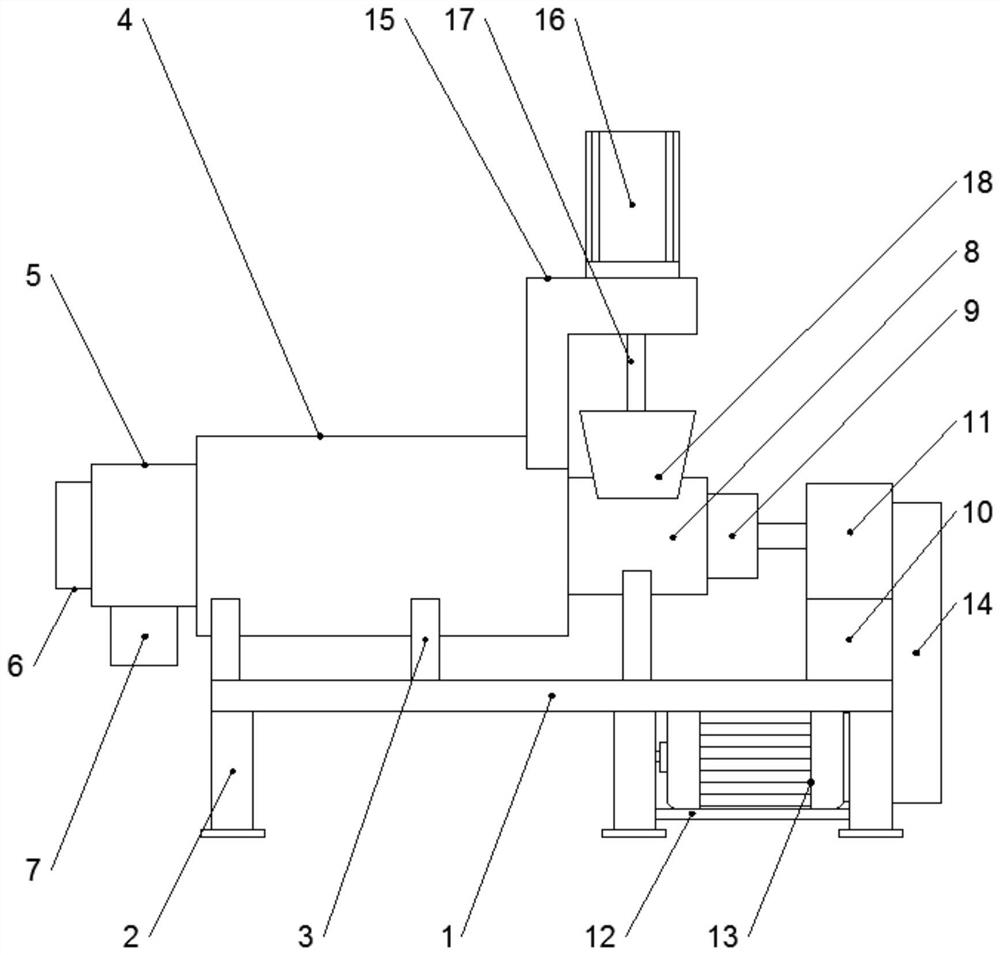

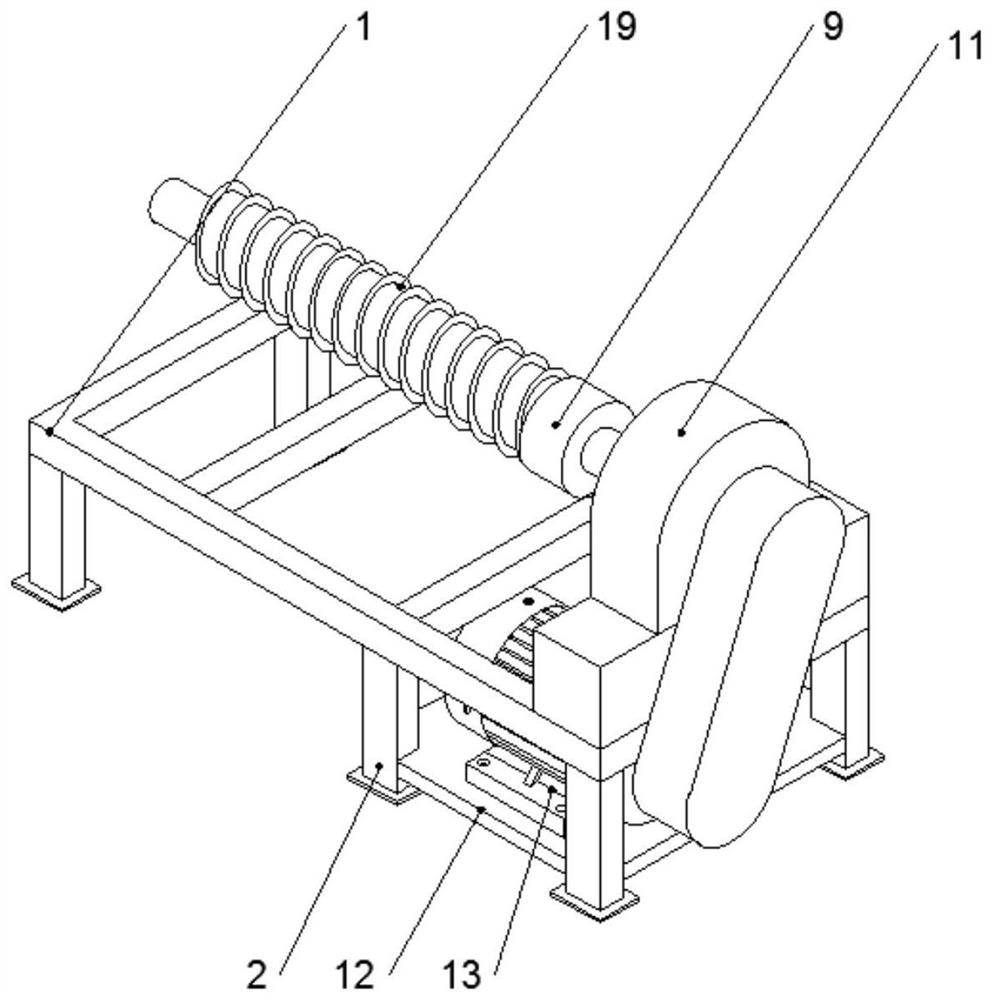

[0021] Example: such as Figure 1-3 As shown, a bio-organic fertilizer granulator of the present invention includes a frame 1, a first cylinder 4, a discharge port 7, a second cylinder 8 and a hopper 18, and the bottom end of the frame 1 is fixedly connected with six Outrigger 2, three brackets 3 are fixedly connected to the top of the frame 1, the top of the brackets 3 is fixedly connected to the first cylinder 4, one side of the first cylinder 4 is fixedly connected to the granulation tube 5, and one side of the granulation tube 5 is fixedly connected There is a bearing seat 6, the bottom end of the granulation cylinder 5 is fixedly connected with a discharge port 7, the other side of the first cylinder 4 is fixedly connected with a second cylinder 8, and the second cylinder 8 is fixedly connected with a shaft coupling 9. A fixed table 10 is fixedly connected to one side of the top of the frame 1, a speed reducer 11 is fixedly connected to the top of the fixed table 10, a sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com