Notebook type stepped emulsification or reaction micro-device module

A micro-device and stepped technology, applied in the field of microfluidics, can solve problems such as droplet or bubble group interference, uneven flow distribution, etc., and achieve the effect of convenient switching of working conditions, simple amplification method, and enhanced uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

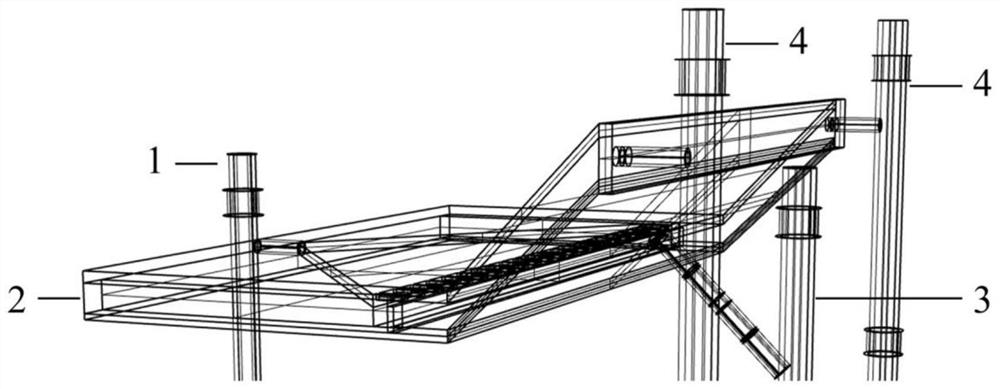

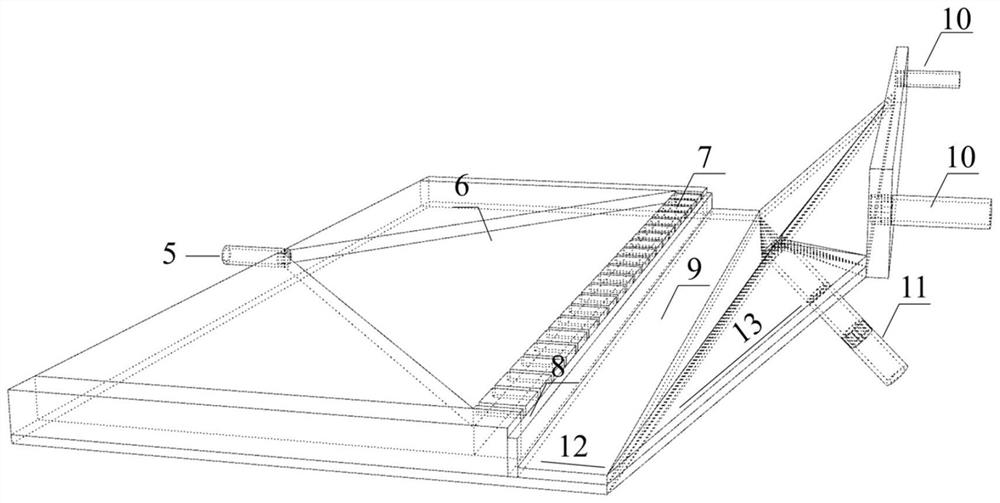

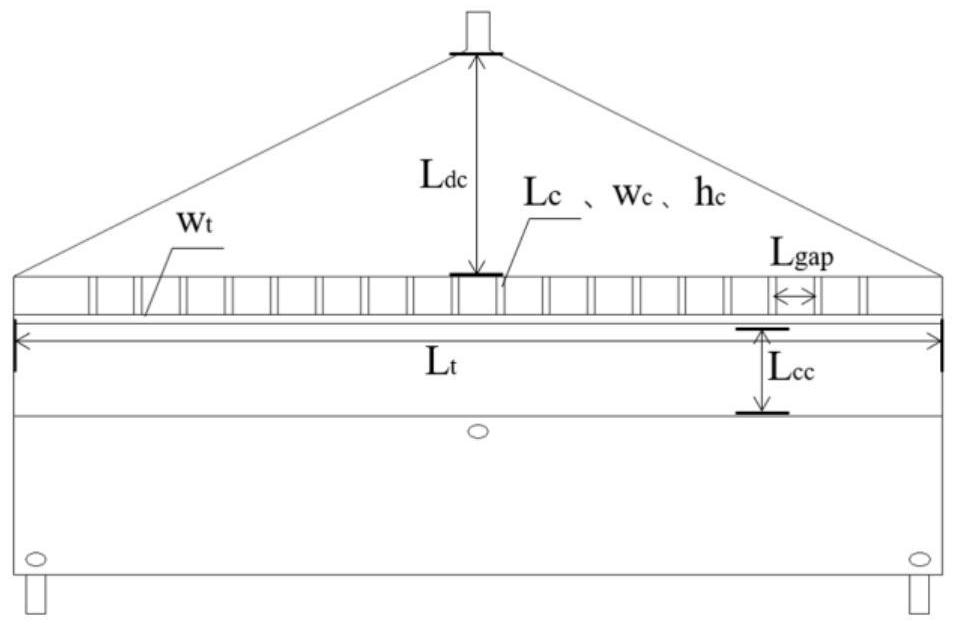

[0027] The "notebook" type step emulsification or reaction micro-device module structure of the present invention is as follows figure 1 and figure 2 As shown, the dispersed phase enters the dispersed phase buffer chamber 6 through the dispersed phase delivery pipeline 1 and the dispersed phase delivery branch pipeline 5 in sequence, and the continuous phase enters the product collection chamber 9 through the continuous phase delivery pipeline 2 and the continuous phase delivery branch pipeline 11 in sequence. In the micro-device, the dispersed phase enters the product collection chamber 9 through the parallel micro-channel group 7 and the step structure 8 in sequence, and completes the emulsification process to generate monodisperse micro-droplets or bubbles. The tiny droplets or bubbles then flow into the product transport channel 4 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com