A robot that smashes burnt objects with rapid impact

A technology of burning objects and robots, which is applied in the direction of grain processing, etc., can solve the problems of movement mechanism vibration and uncontrollable impact force, etc., and achieve the effect of improving mashing quality, saving mashing time, and simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

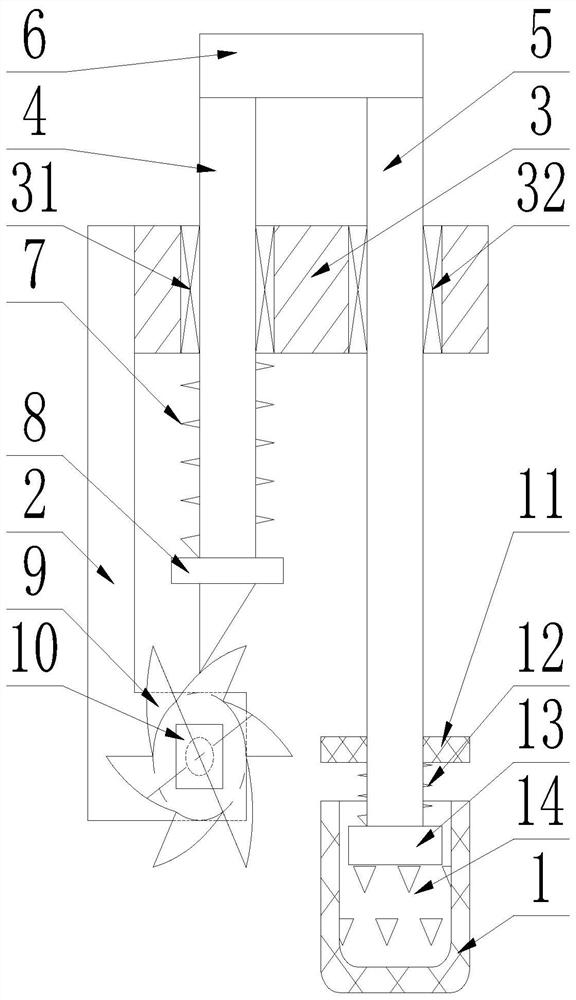

[0017] see figure 1 As shown, a robot for quickly impacting and smashing burning objects of the present invention includes a frame 2, a motor 10 and a bearing frame 3 fixedly installed on the frame 2.

[0018] see figure 1 As shown, the output shaft of the motor 10 is fixedly equipped with a ratchet 9, and the contour line of the ratchet of the ratchet 9 is composed of a section of arc and a radial line; the radial line is not less than 1 / 2 of the maximum radius of the ratchet 9 The radial line of the ratchet makes the end of the active impact rod 4, that is, the ratchet of the right triangle, have a sudden displacement, and then the active impact rod 4 drives the passive impact rod 5 to move downward quickly through the connecting rod 6, and then the impact plate 13 is quickly moved. Impact the block-shaped burning material 14 in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com