Two-component multi-proportion adhesive gun

A multi-proportion, two-component technology, used in coatings, devices for coating liquids on surfaces, etc., can solve problems such as lack of tools, and achieve the effects of reducing production and use costs, increasing versatility, and easy and labor-saving operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

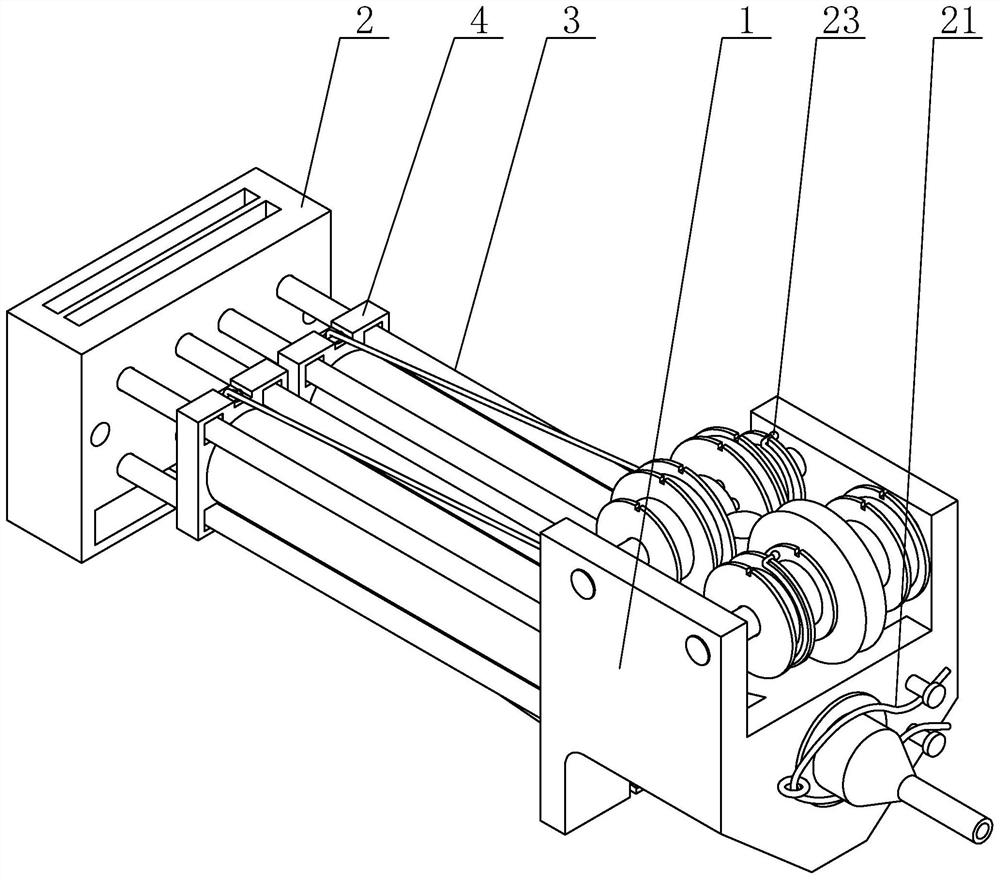

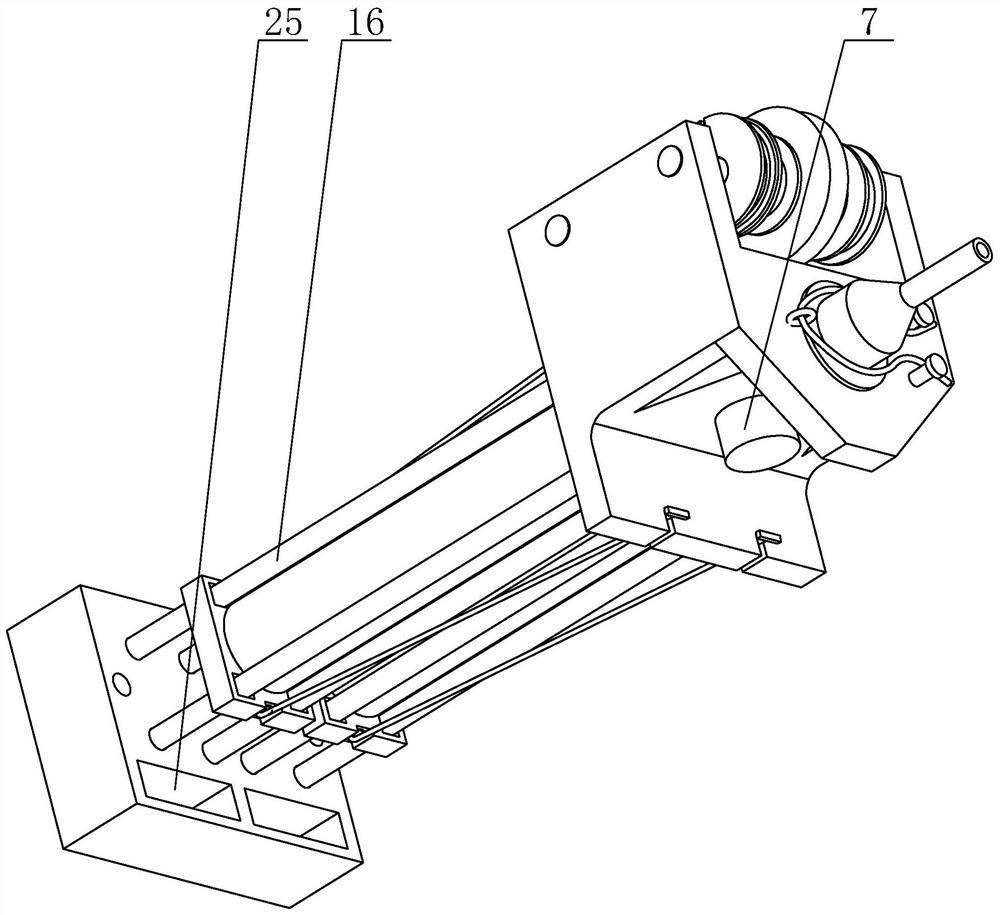

[0051] Embodiment 1: a two-component multi-proportion glue gun, comprising an end base 1 and a tail base 2, the tail base 2 is provided with a grip hole 24 and a battery hole 25, a lithium battery is placed in the battery hole, and the end base 2 Two sets of guide rails 3 are arranged between the seat 1 and the tailstock 2, and each set of guide rails 3 is formed by inserting four guide rods 16, and push plates 4 are slidingly arranged on the guide rails 3 of the two groups, and the The guide rod 16 runs through the push plate 4 and is arranged in a rectangular array on the push plate 4. The side of the push plate 4 is provided with a push rod for pushing the hard adhesive, and the two push plates 4 are provided with a traction rope 5. The end seat 1 A worm 6 is provided for rotation at the upper center position, and a drive motor 7 connected to the worm 6 is provided at the bottom of the end seat 1, and a transmission mechanism is provided on both sides of the worm 6, and a gl...

Embodiment 2

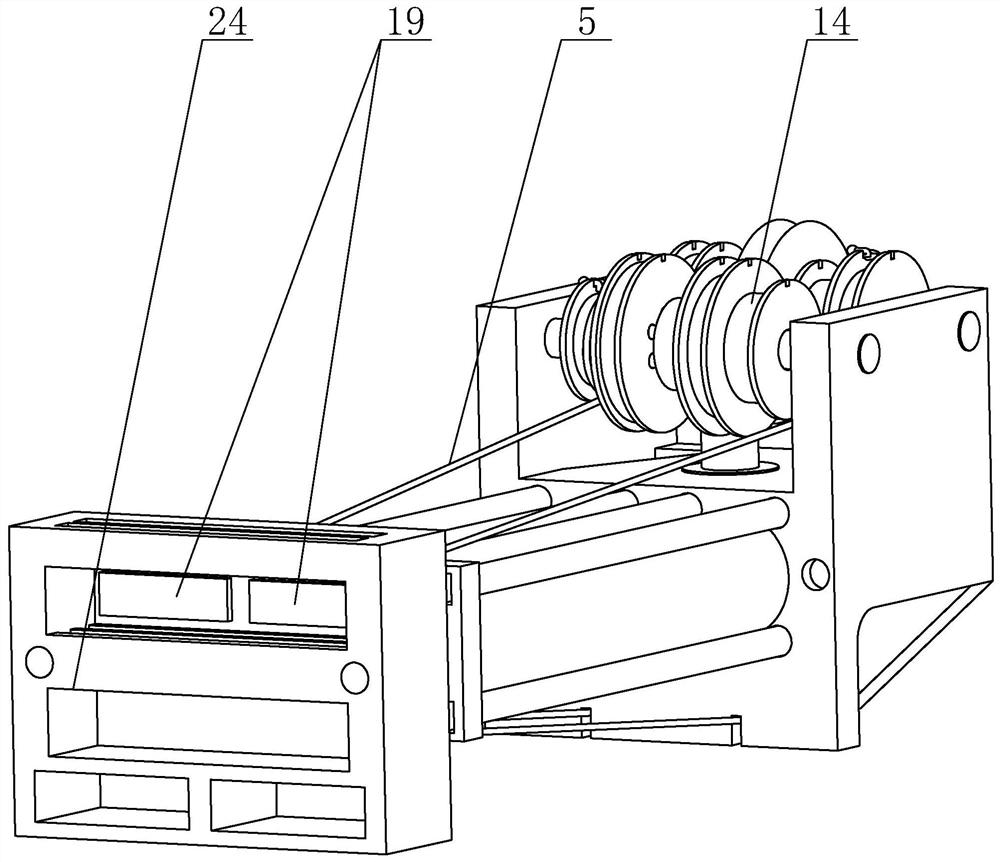

[0055] Embodiment 2: a two-component multi-proportion glue gun, including an end base 1 and a tail base 2, the tail base 2 is provided with a grip hole 24 and a battery hole 25, a lithium battery is placed in the battery hole, and the end base 2 Two sets of guide rails 3 are arranged between the seat 1 and the tailstock 2, and each set of guide rails 3 is formed by inserting four guide rods 16, and push plates 4 are slidingly arranged on the guide rails 3 of the two groups, and the The guide rods 16 run through the push plate 4 and are arranged in a rectangular array on the push plate 4, and a spare guide rod is inserted on the outside of the guide rail 3 for better surrounding and fixing the adhesive of the flexible package. 16 plug-fit rectangular through holes 17, the bottom guide rods 16 of the two groups of guide rails 3 are detachably connected with the tailstock 2, so that the bottom guide rods 16 can be disassembled from the tailstock 2, and can be firmly installed with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com