Angle-adjustable chamfering tool

A technology of chamfering tools and angle adjustment, which is applied to the lathe tools, tool holders, manufacturing tools, etc., which can solve the problems of enterprises increasing the cost of tool purchases, chamfering processing cannot be accurately guaranteed, and tool costs remain high. Achieve the effects of ingenious and reasonable structural design, good versatility, and guaranteed processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

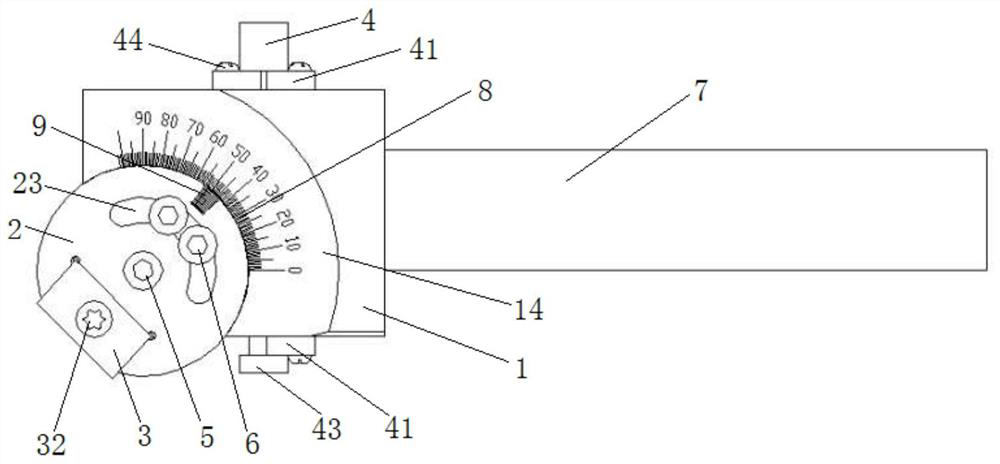

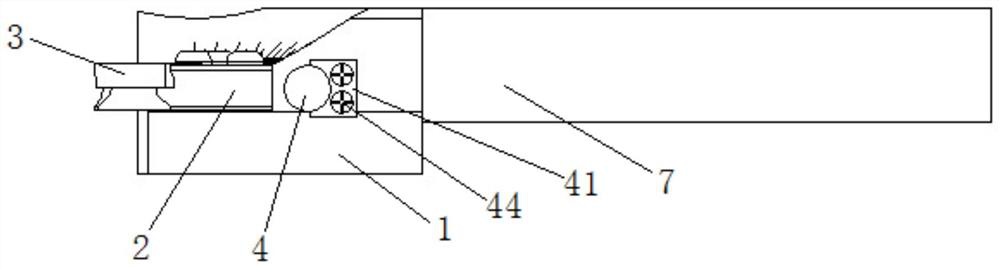

[0036] The embodiment is basically as Figure 1 to Figure 3 As shown: this embodiment provides an adjustable angle chamfering tool, including a cutter body 1, a knife seat 2 and a blade 3, and also includes an adjusting screw 4, a rotating screw 5 and a locking mechanism; the structure of the cutter body 1 is specifically as follows Figure 4 As shown, the cutter body 1 is provided with an arc-shaped mounting groove 11 for installing the cutter holder 2, so that the cutter holder 2 is rotationally connected with the cutter body 1 through the positioning round boss 21 at the bottom and the rotating screw 5, and through The locking mechanism fixes the knife seat 2 on the knife body 1. The locking mechanism includes at least two compression screws 6, and a threaded hole matched with the compression screws 6 is provided on the bottom surface of the arc-shaped installation groove 11; the knife seat The structure of 2 is as follows Figure 5 and Figure 6 As shown, the knife seat ...

Embodiment 2

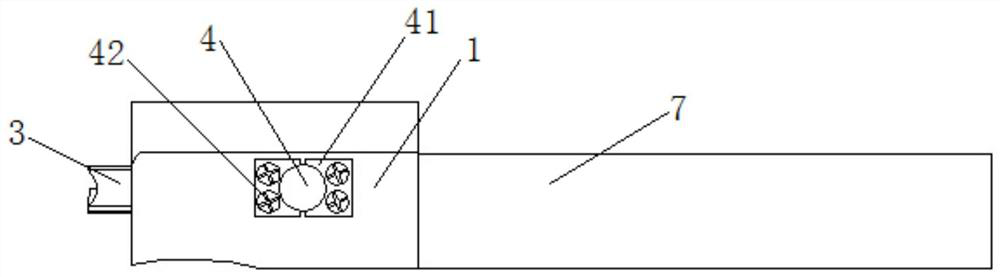

[0046] Embodiment 2 is basically the same as Embodiment 1, the difference is: please combine Figure 1 to Figure 7 As shown, this implementation fully considers the precision thread cooperation between the adjusting screw 4 and the outer circular surface of the knife seat 2 to realize the precise transmission connection. Two through holes 13 are used to install the adjusting screw rod 4; and the positioning plate 41 for fixing the adjusting screw rod 4 is provided on the both sides of the cutter body 1 near the second through hole 13, and the above-mentioned structure is used to adjust the chamfering angle of the tool The adjusting screw 4 and the cutter body 1 are reliably installed together, and the matching connection between the adjusting screw 4 and the cutter seat 2 is located inside the cutter body 1 without being disturbed by the external environment.

[0047] Such as Figure 7 As shown, the middle part of the adjusting screw 4 is formed with a thread that matches the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com