Pressurized drilling device and implementation method thereof

A drilling device and drill rod technology, which is applied to feeding devices, boring/drilling, drilling/drilling equipment, etc., can solve the problems of no working channel, small stroke, long cycle, etc. The effect of reducing frictional resistance and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

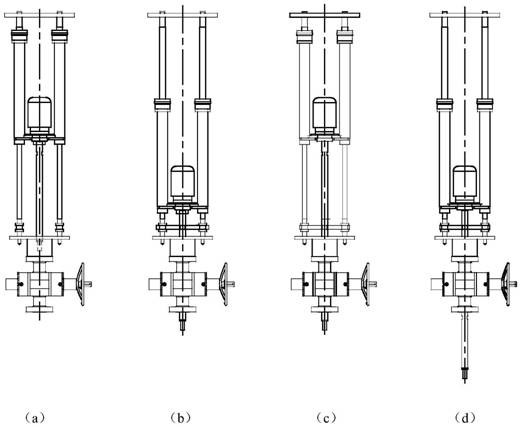

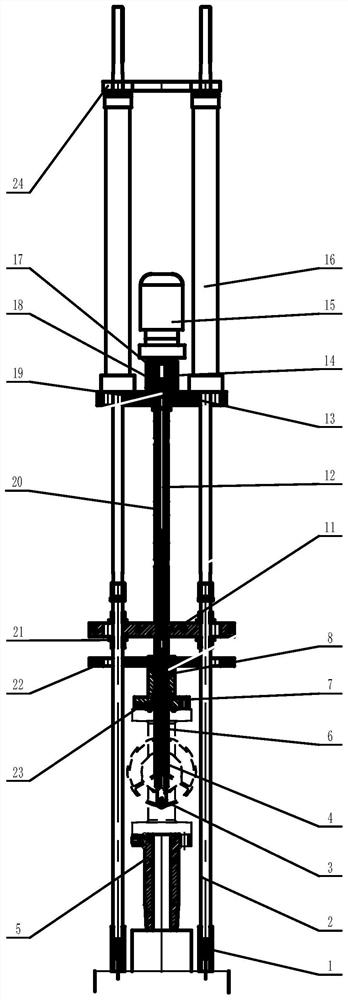

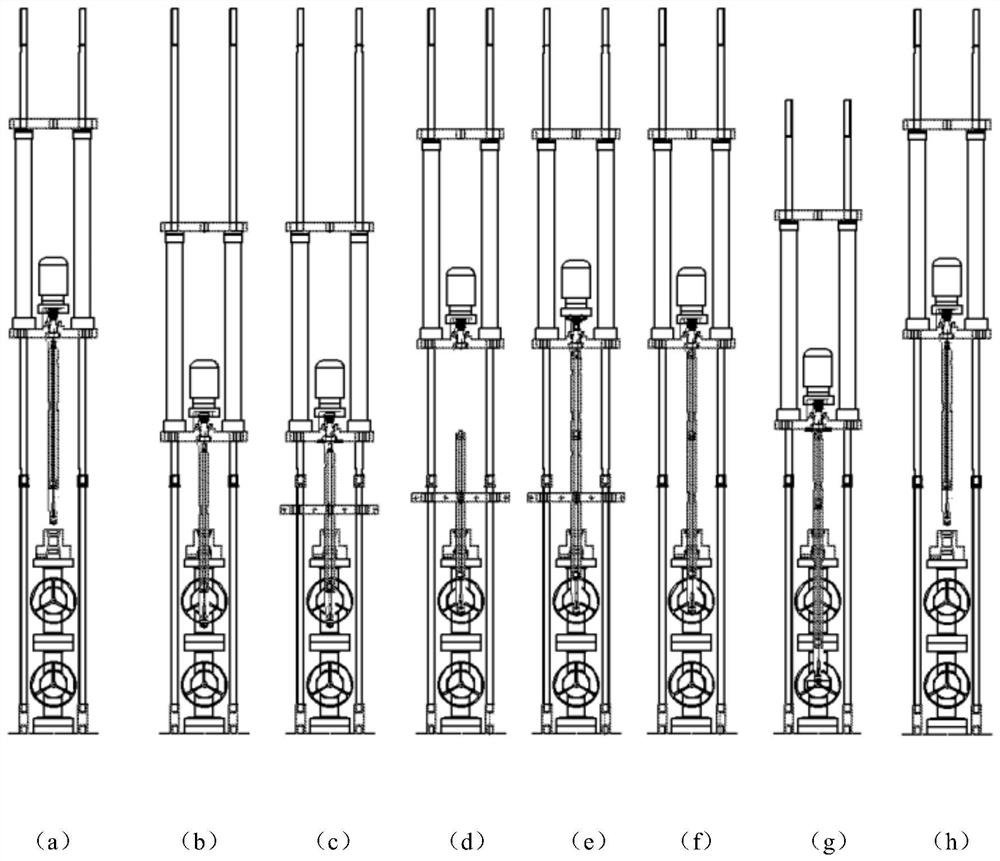

[0038] see Figure 2-3 , a method for implementing a pressurized drilling device, comprising the following steps:

[0039] 1) Device assembly: first install the left and right column components, install the fixing nuts of the device column on the fixed seat of the valve to be drilled, and install the column, column extension rod, hydraulic cylinder, and hydraulic cylinder beam in sequence. Then install the blowout preventer flange assembly, hydraulic motor assembly, center drill pipe assembly and hydraulic control console for trial operation.

[0040] 2) Connect the drill pipe to the crossbeam of the oil cylinder, adjust the drilling depth of the drill pipe to ensure the centering of the drilling hole; tighten the bolts everywhere, and switch the valves that need to be opened and closed according to the regulations, and complete the preparation work before drilling ;

[0041] 3) Device pressure test: The device is subjected to a pressure test according to the test process re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com