Welding, polishing and dust removal integrated platform

A platform and protective cover technology, applied in the direction of grinding machine, grinding frame, grinding bed, etc., can solve the problems affecting the lungs, nasal breathing health, dust cannot be collected effectively, skin burns, etc. Quick gray, simple structure, large air suction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

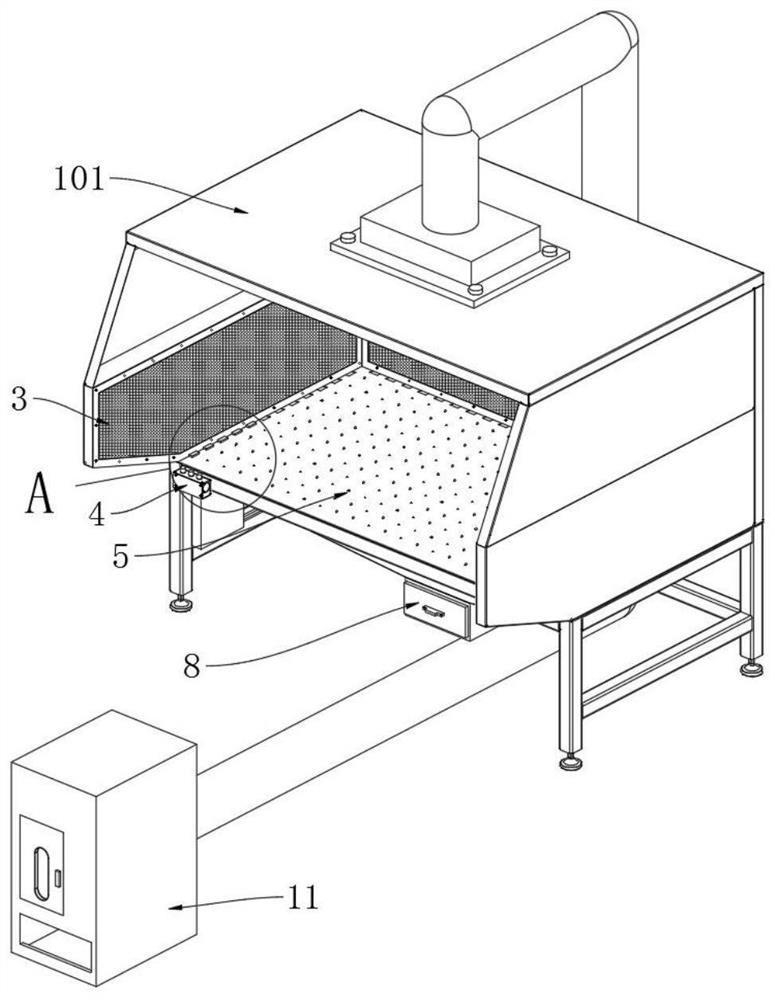

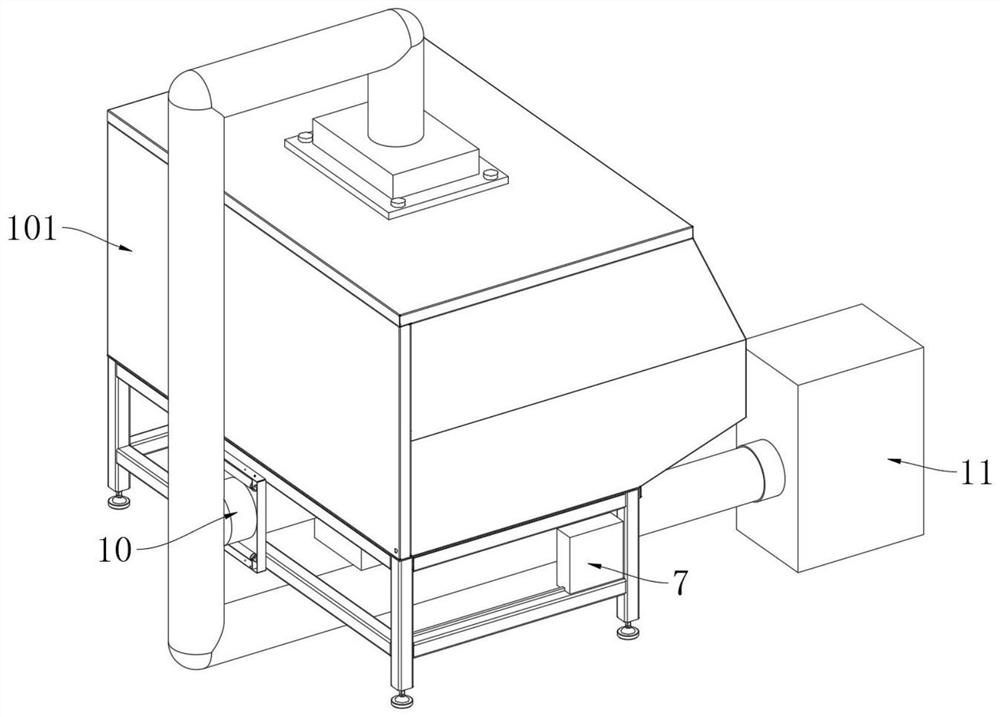

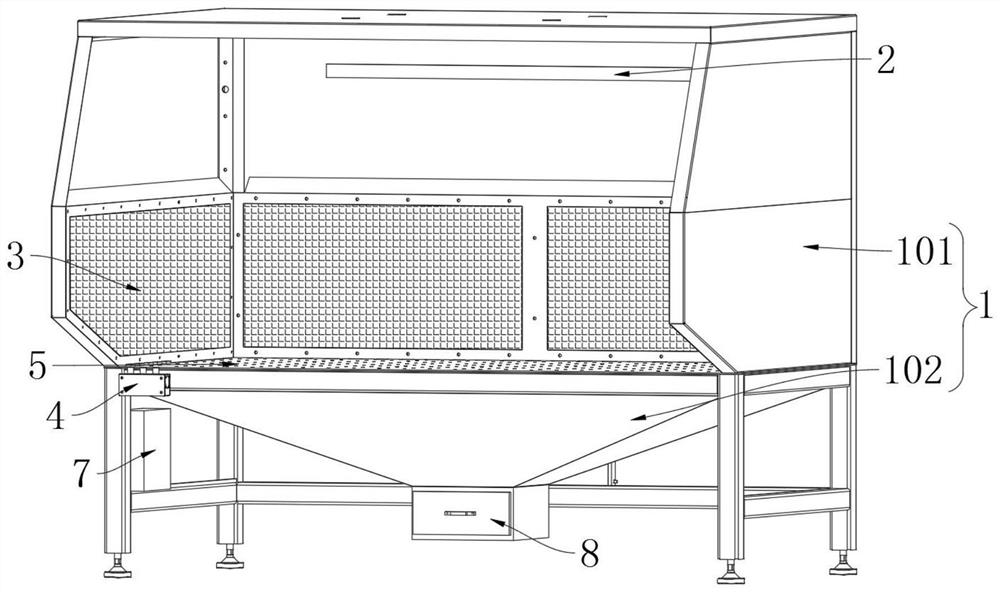

[0030] as attached figure 1 to attach Figure 7 Shown:

[0031] The invention provides an integrated platform for welding, grinding and dust removal, which includes a grinding platform 1; a support frame is installed on the grinding platform 1, and four support rods are installed on the bottom of the grinding platform 1; an LED explosion-proof lamp 2 is installed on the grinding platform 1, And the inner side of the grinding platform 1 is installed with anti-spark rebound extra-thick encrypted iron mesh 3; the front side of the grinding platform 1 is equipped with a one-key full control button 4, and a honeycomb high-quality floor platform 5 is installed on the grinding platform 1, one-key full control One side of the button 4 is equipped with a 220V power outlet box 6; a rectangular support rod is installed on the support rod of the grinding platform 1, and an intelligent automatic air volume changer 7 is installed on the support rod; The gray drawer material box 8 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com