Horizontal type saw notch machine capable of adjusting saw notch depth conveniently

A sawing machine and sawing technology, which is applied to circular saws, sawing equipment, wood processing appliances, etc., can solve the problem of inconvenient collection of sawdust for long-term use of the sawing machine, the impact of the saw blade on the service life of the saw blade, and the inconvenience of the depth of the saw scar. adjustment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

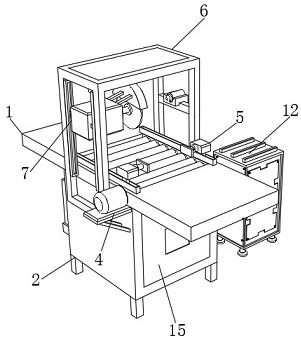

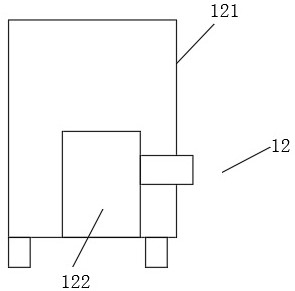

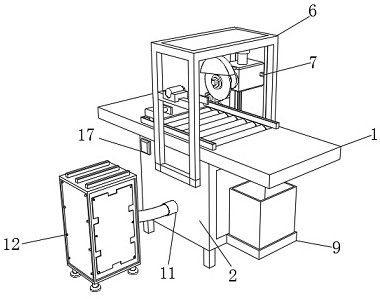

[0032] see Figure 1-10, the present invention provides the following technical solutions: a horizontal sawing machine for conveniently adjusting the depth of sawing marks, including a workbench 1, a waste cabinet 2 is fixedly connected to the middle part of the bottom end of the workbench 1, and a first opening is provided in the middle part of the top end of the workbench 1. Hole 3, the first opening 3 is rotatably connected with a feeding mechanism 4, the top of the workbench 1 is located at the first opening 3 and both sides are fixedly connected with a clamping mechanism 5, and both sides of the waste cabinet 2 are fixedly connected with a fixing frame 6, fixed A cutting mechanism 7 is slidingly connected to one side of the frame 6, a protection mechanism 8 is fixedly connected to the top of the cutting mechanism 7, a first support frame 9 is fixedly connected to the bottom of one end of the waste cabinet 2, and a flushing mechanism 10 is fixedly connected to the top of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com