Impactor air distribution device and matched impactor

A technology of impactor and gas distribution, which is applied to the driving device for drilling in the borehole, drilling equipment, earthwork drilling and production, etc. It can solve the problems of insufficient impact energy, high cost of reserve impactors, and large waste of impact energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

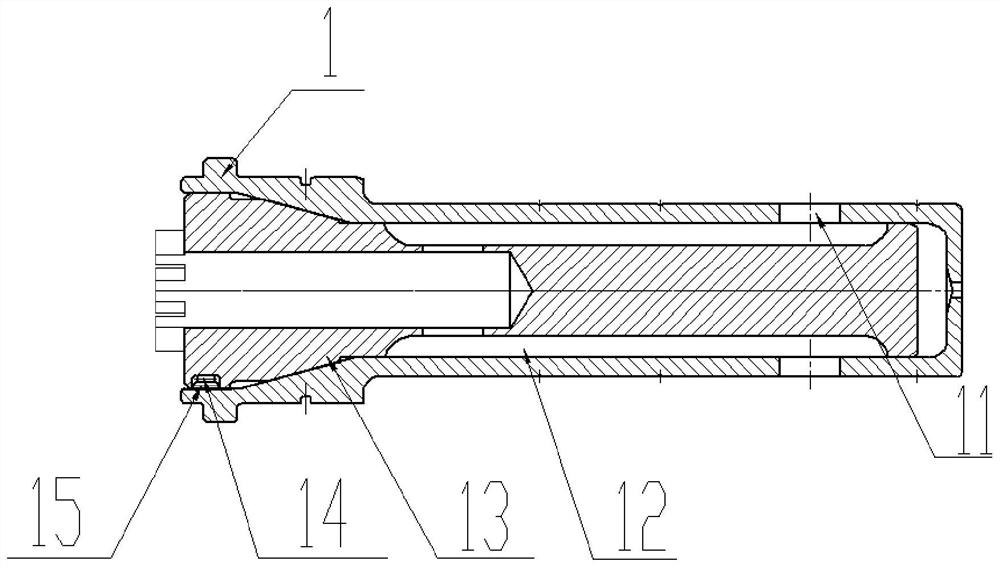

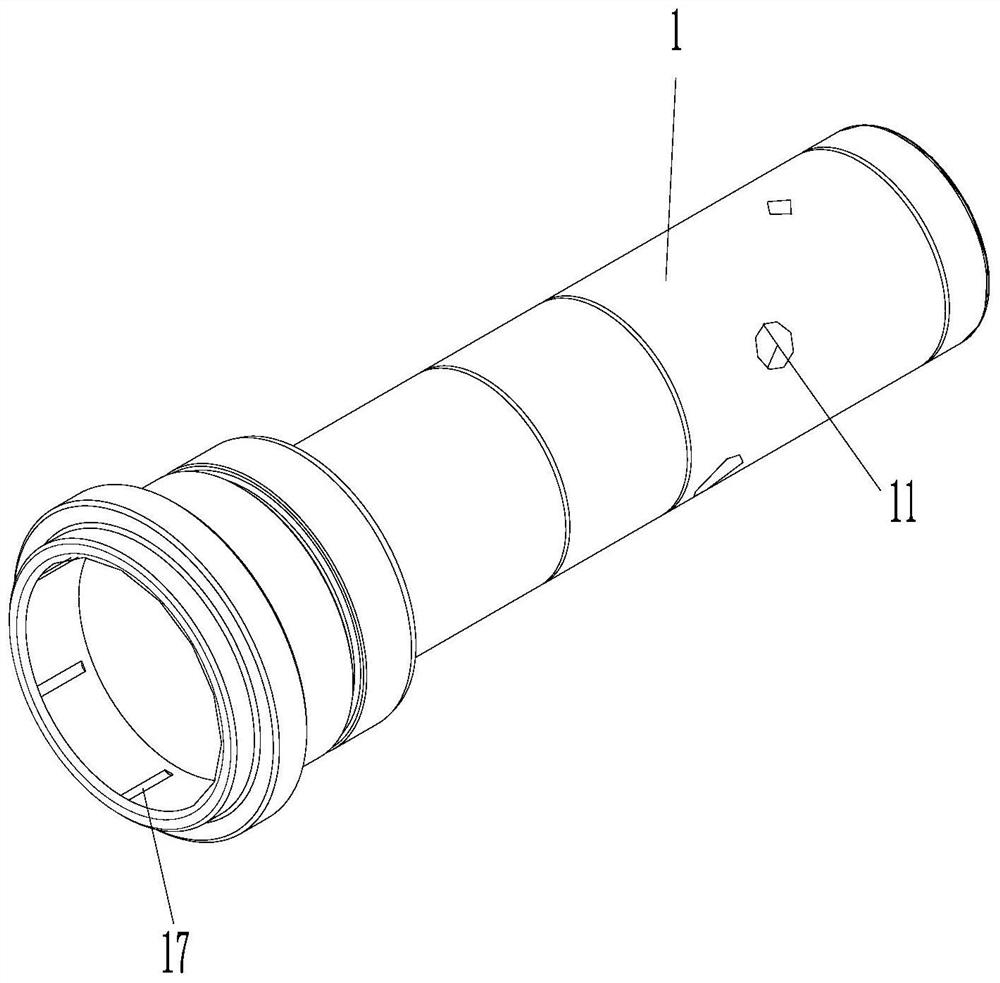

[0025] Such as figure 2 , 3 , 4, a gas distribution device for an impactor, including a gas distribution rod 1 installed in the impactor, the middle part of the gas distribution rod 1 is provided with a cavity that matches the size of the gas distribution rod core 13, the gas distribution rod 1 The gas rod core 13 is coaxially sealed and installed in the cavity of the gas distribution rod 1. The middle part of the gas distribution rod core 13 is arranged with an air inlet channel along the axial direction, and the outer wall of the gas distribution rod core 13 is provided with multiple sets of The gas distribution and air groove groups arranged in the direction, each group of gas distribution and gas groove groups include two gas distribution and gas grooves 12, and the gas distribution and gas grooves 12 are symmetrically arranged around the central axis of the gas distribution rod core 13. An air distribution air channel is formed between the air groove 12 and the inner wa...

Embodiment 2

[0030] Embodiment 2: As an application of the gas distribution device of the impactor of the device:

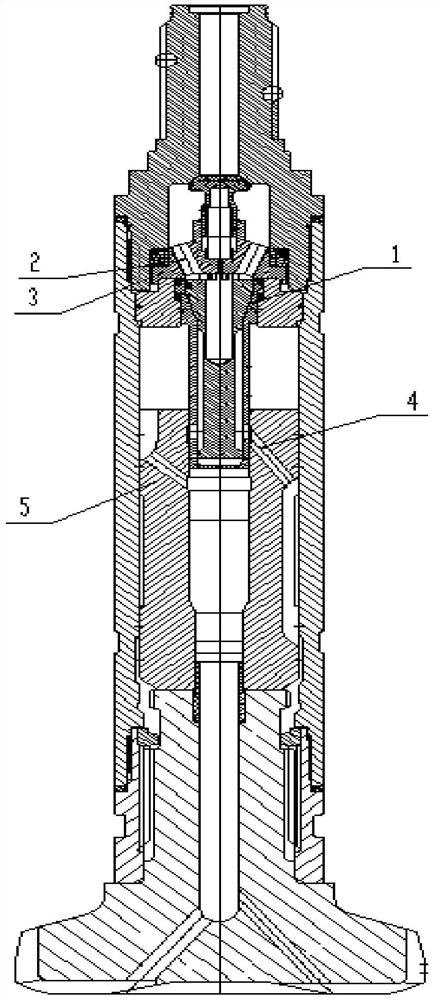

[0031] Such as figure 1 As shown, it includes an impactor, the impactor includes the impactor gas distribution device in Embodiment 1, and the impactor gas distribution device is installed between the check valve seat 3 and the piston 5 of the impactor. The air distribution device of the impactor is provided with clamping parts, and the outer cylinder of the impactor is provided with a plurality of card slots matching with the clamping parts. In the outer cylinder of the impactor, and axially positioned in the outer cylinder through the impactor joint installed on the outer cylinder of the impactor, the air channel 2 of the check valve seat communicates with the air distribution channel through the air intake channel of the valve rod core 13, the said The gas distribution rod 1 is inserted in the intake passage of the piston 5 .

[0032] The configuration process of the spe...

Embodiment 3

[0035] The application of specific examples is as follows:

[0036] Three sets of air distribution holes are set on the air distribution rod 1, the position of the first set of air distribution holes makes the maximum stroke of the piston 73mm, the position of the second set of air distribution holes makes the maximum stroke of the piston 82mm, and the position of the third set of air distribution holes The position of the air hole makes the maximum stroke of the piston 94mm,

[0037] There are three sets of air distribution channels on the air distribution rod core 13, the flow area of the first group of air distribution channels is 480mm 2 , the flow area of the second group of air distribution channels is 1050mm 2 , the flow area of the third group of air distribution channels is 1780mm 2 .

[0038] In this example, the requirements for hole formation: the hole diameter is 230-240mm, and the water output reaches 20m 3 / min.

[0039] The process of designing the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com