Underground temporary fold line steel frame supporting system and construction method

A technology of support system and temporary support, applied in underground chambers, temporary shields, earthwork drilling, etc., can solve the problem of high construction cost, and achieve the effect of reducing construction cost and reducing repeated configuration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings.

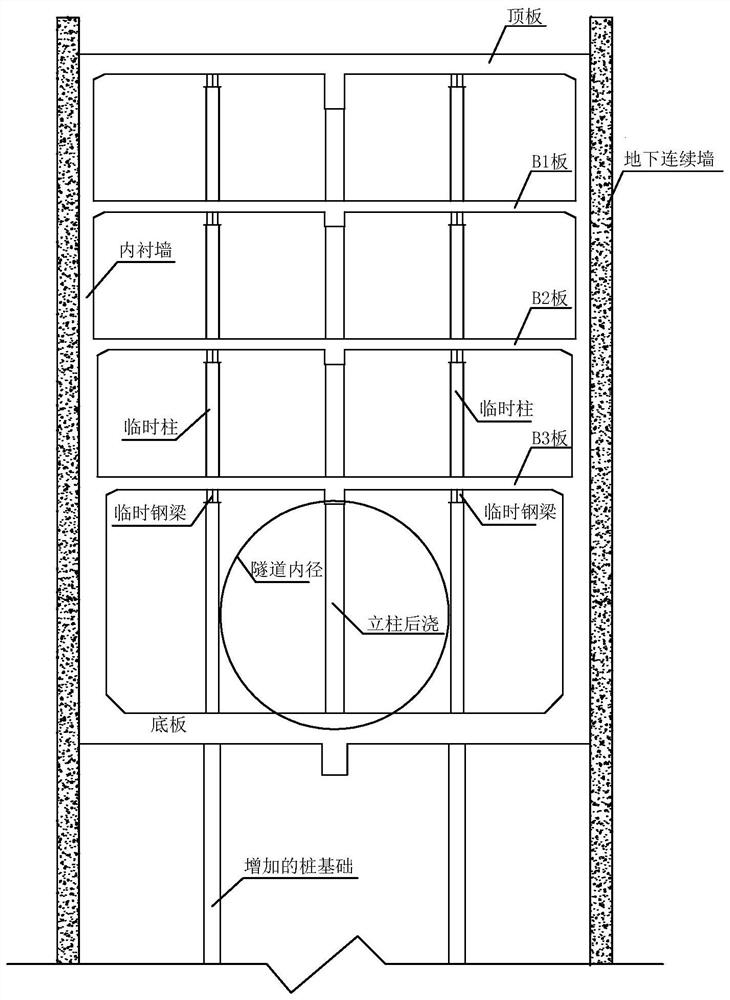

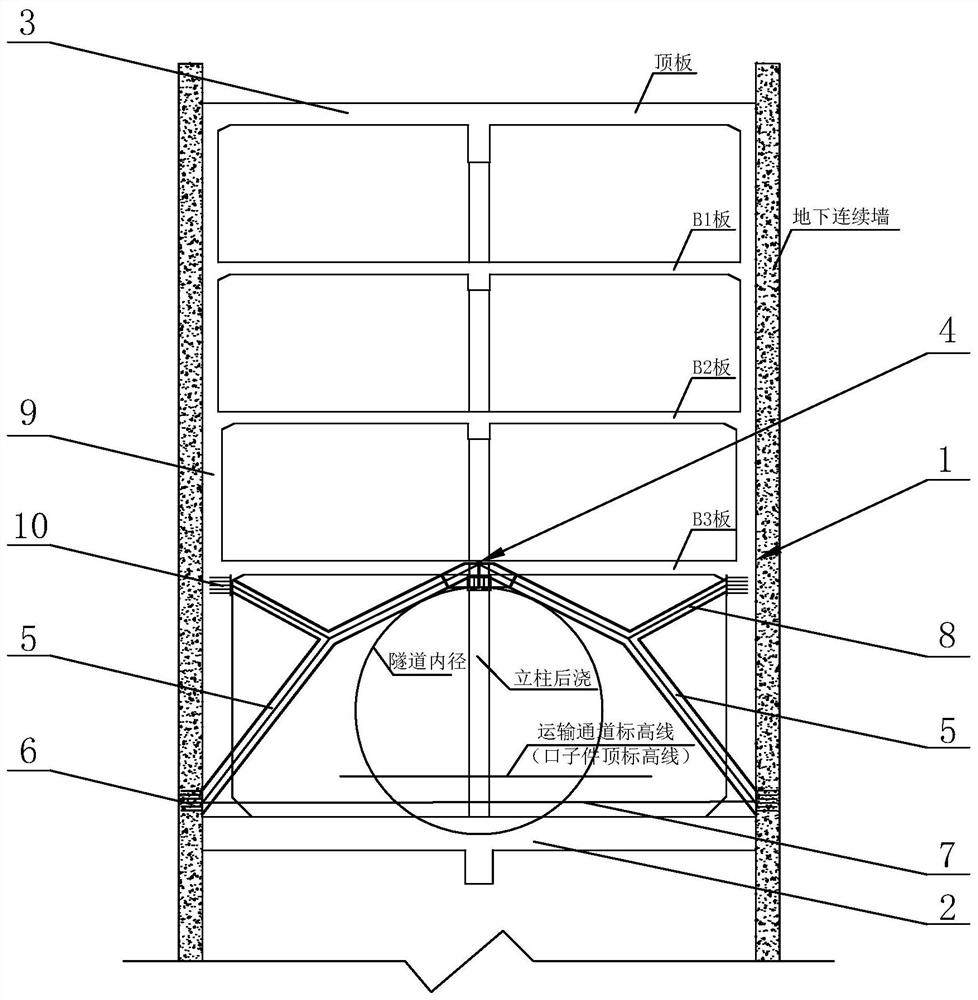

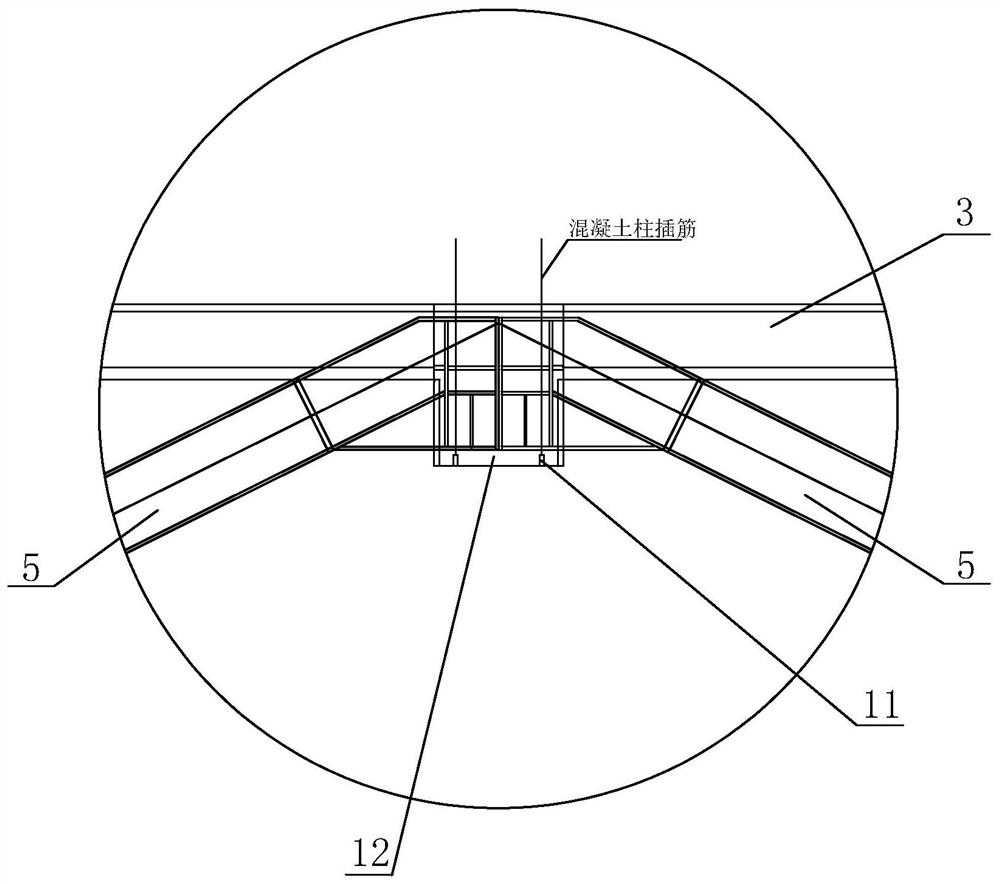

[0043] A support system for underground temporary broken-line steel frames, such as figure 2 and image 3 As shown, it includes the foundation pit underground diaphragm wall 1 formed by the underground diaphragm wall. The bottom of the foundation pit underground diaphragm wall 1 is formed by pouring concrete to form a floor 2. A floor 3 is arranged above the floor 2. Permanent structural columns are arranged between the three floors. The bottom surface of the floor 3 on the next floor is provided with a plurality of support points 4 along the centerline of its length direction, and temporary support assemblies are arranged on both sides of the support points 4 between the floor 3 and the bottom plate 2 to form an arch structure, and the temporary support assemblies It is only connected to the floor 3 at the support point 4.

[0044] Since the temporary sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com