Methane static pressure exhaust construction method

A biogas and static pressure technology, used in gas discharge, safety devices, mining devices, etc., can solve problems such as large differences in stratum bearing capacity, rupture and damage of segments, and deformation of tunnel structures, achieving favorable emissions and high costs. , the effect of long construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

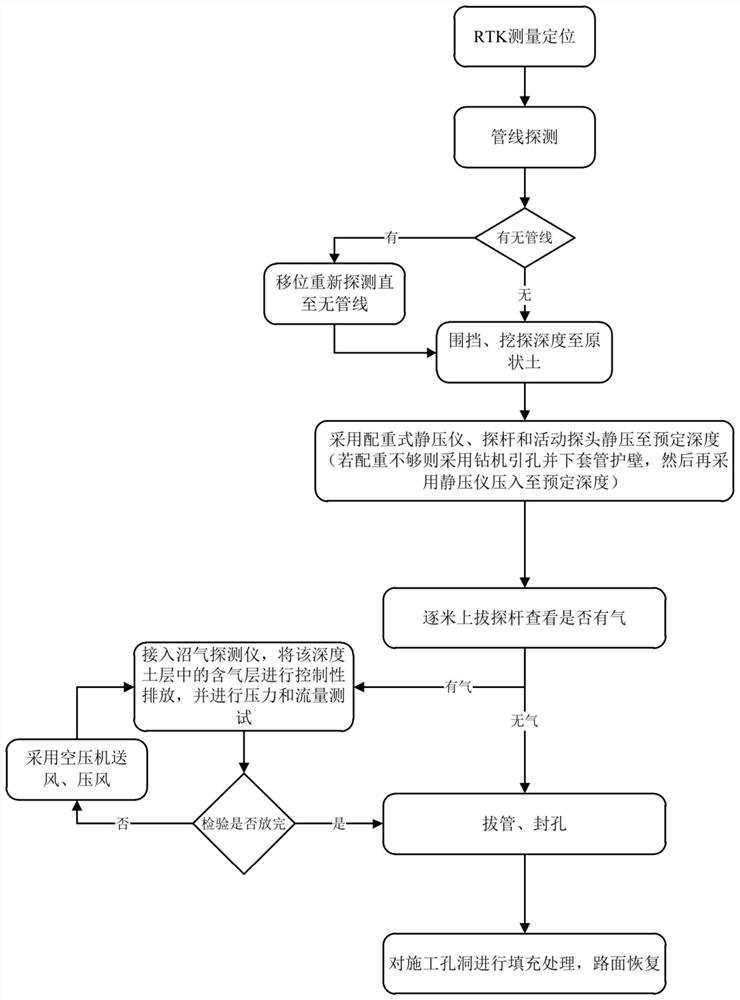

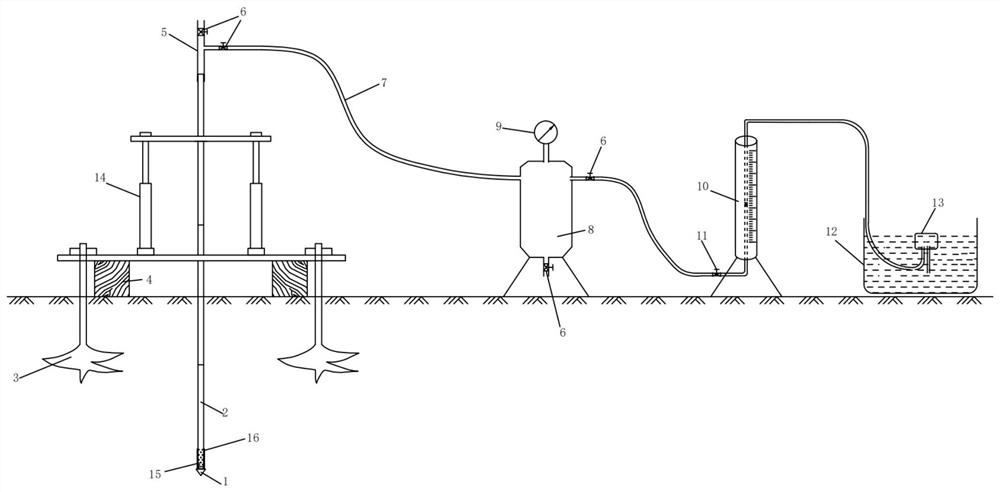

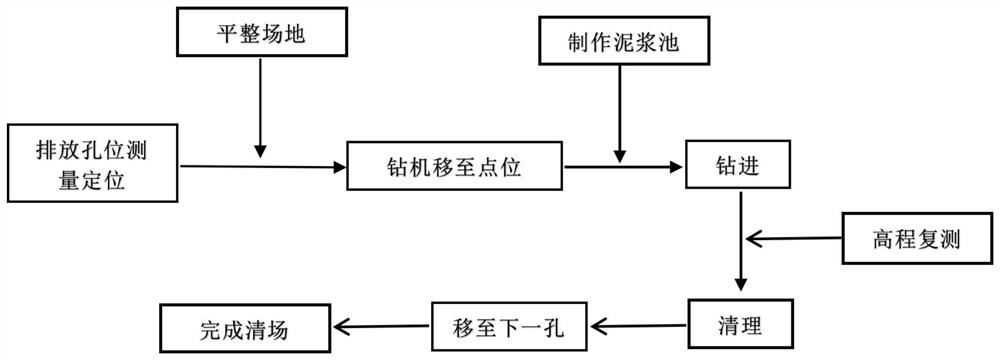

[0041] as attached figure 1 and 2 As shown, a biogas static pressure exhaust construction method provided for an embodiment of the present invention includes the following steps:

[0042] 1. Measurement positioning:

[0043] First, according to the specific location of each biogas discharge hole determined by the design, the coordinates are collected in the electronic topographic map, and then the surveyor adopts the GPS-RTK method on the basis of the ZJCORS platform, according to the "Global Positioning System Real-time Kinetic Measurement (RTK) Specification" (CH / T2009-2010) requires surveying, and the coordinate results adopt the local coordinate system and the 1985 national elevation datum; since the points of this project are on land, the point marks are marked with red spray paint to prevent man-made damage; if the biogas discharge hole needs to be moved, it should pass through The person in charge of the project and the general contractor, supervisor, designer, and t...

Embodiment 2

[0126] Apply the biogas static pressure exhaust construction method in Example 1 to the section from Hejing Road Station to Qingliu Road Station, the section from Qingliu Road Station to Qingpeng Road Station, and the section from Qingpeng Road Station to Yipeng in the first phase project of Hangzhou Metro Line 8 East 2nd Road station section project.

[0127] Among them, the section from Jinglu Station to Qingliu Road Station is an underground shield section. This section mainly passes through the residential area of Jianyi Village and Xiaosibuzhi River. The length of the line is 987.968m; left DK10+738.712~left DK11+726.678, the length of the left line is 2.223m, the length of the left line is 990.189m, and a communication channel is set up in the section.

[0128] Among them, the section from Qingliu Road Station to Qingpeng Road Station is an underground shield section. The line extends eastward after exiting Qingliu Road Station, deflects to the southeast after passing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com