Heat exchanger and temperature control circuit system

A heat exchanger and loop system technology, applied in heat exchange equipment, water heaters, indirect heat exchangers, etc., can solve the problems of space consumption, material and weight, high cost, etc., and achieve the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] All figures are to be understood schematically. In order to improve the clarity of the view, illustrations that are correct in scale have been omitted.

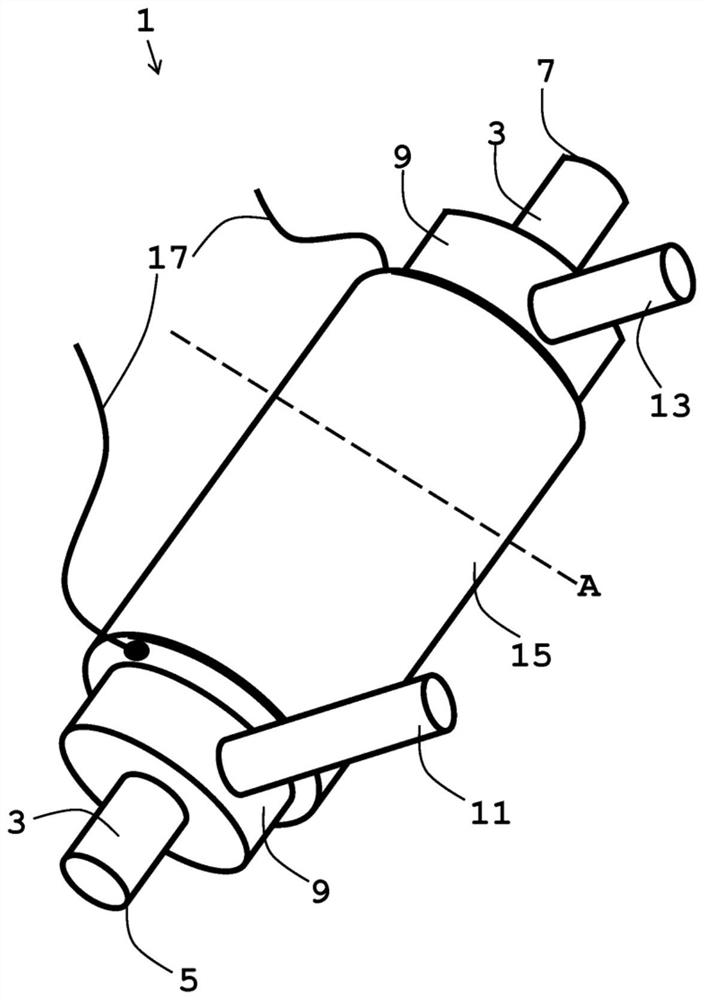

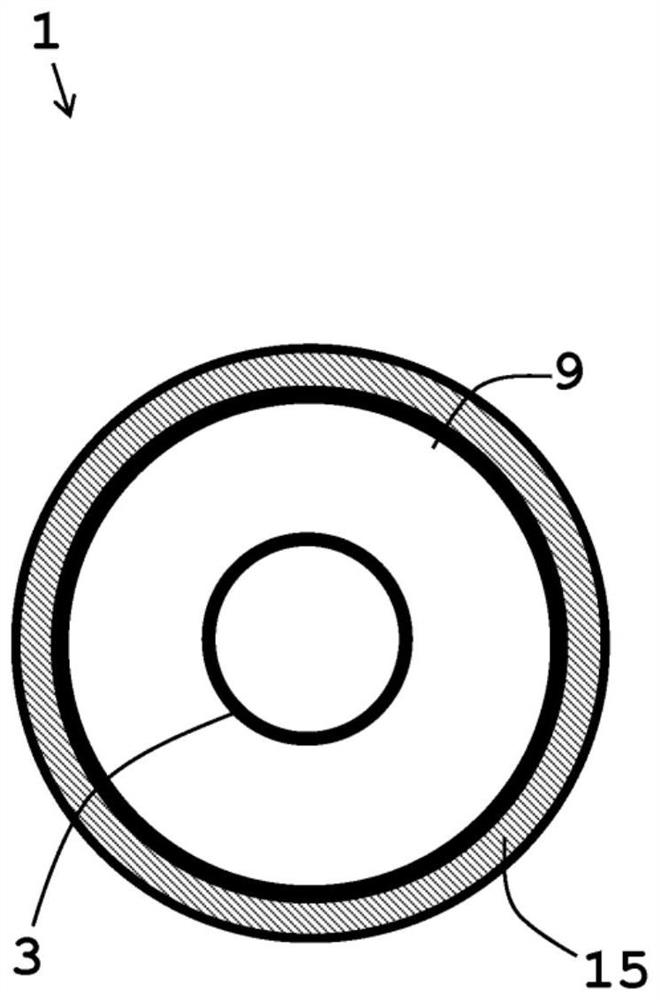

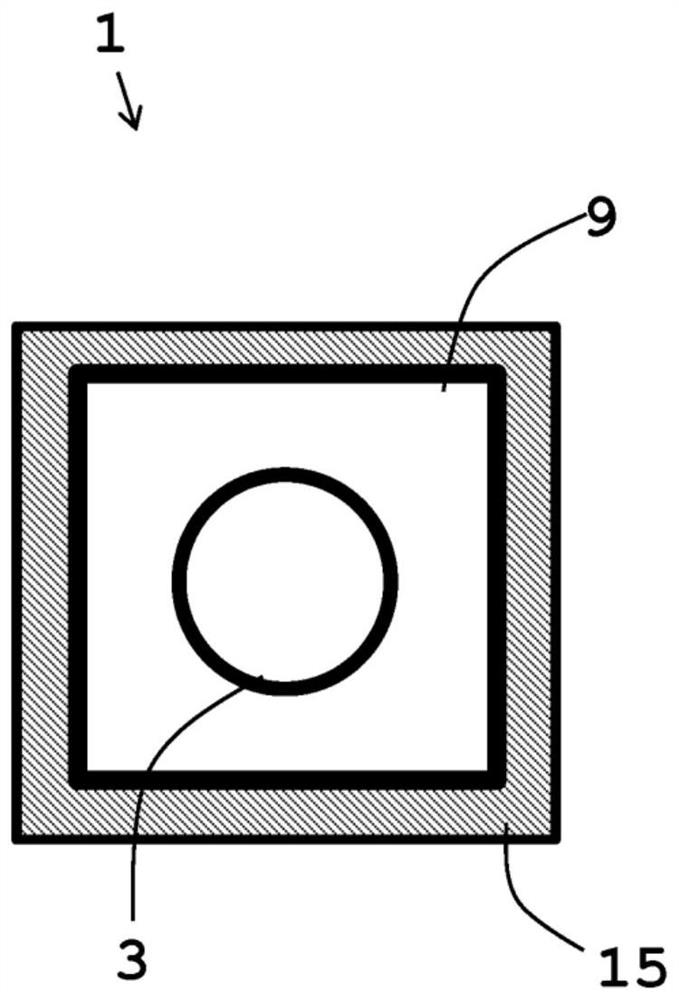

[0035] exist Figure 1a An exemplary embodiment of a heat exchanger 1 is shown in FIG. 1 , which is designed as a fluid-fluid heat exchanger. The line 3 for the first fluid runs in its interior in the direction of the longitudinal axis. The line 3 can be integrated into a fluid circuit by means of its front connection end 5 and its rear connection end 7 . The line 3 is formed as a refrigerant line. The line is suitable for allowing a refrigerant such as R-134a, R-1234yf or R-744 to flow through the line. The line is tubular in shape with a circular cross section. Its tube walls are made of steel or other commonly used materials suitable for this purpose. The line 3 runs coaxially with the line 9 for the second fluid in this line 9 . The line 9 likewise has a tubular shape with a circular cross section, wherein t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com