Automatic sample reserving equipment system and method for grain assay

A sample retention and automatic technology, applied in the direction of sampling device, program control in sequence/logic controller, instrument, etc., can solve the problems of inability to guarantee sample safety, high cost, and large labor load

Pending Publication Date: 2020-11-13

SHANDONG SHOUGUANG JUNENG GOLDEN CORN CO LTD +3

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The current sample retention process needs to rely on manual work. The use of manpower to load samples, store samples, and discard samples is not only labor-intensive, but also the sample retention process is not standardized. At the same time, it takes up some unnecessary space. However, the safety of samples cannot be guaranteed

There are also various sample retention equipment and methods in China. After comparing various methods, the cost is relatively high, the installation space is limited, and the operation is difficult to execute, etc.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

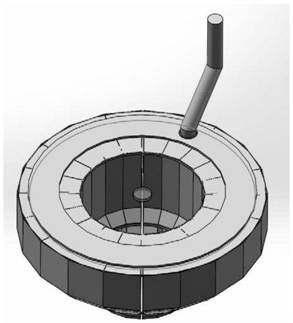

[0017] For the re-inspection of the samples in the disc-type sample box, input the sample box number in the system computer, the sample box will automatically turn to the position of the sampling port, manually pull the sampling cover, and the sample will flow out for re-inspection, avoiding manual search sample.

[0018] Through the above experiments, the automatic sample retention system can completely replace manual sample retention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

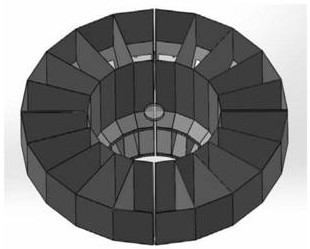

The invention discloses an automatic sample reserving equipment system and method for grain assay, and belongs to the technical field of food processing. The equipment system comprises a machine base,a conveying auger, a driving system, a feeding system, a material discarding system, a PLC system, a disc type sample box, various electromagnetic valves and connecting pipelines. The sample reserving method comprises the steps that after grain sampling is completed, samples pass through a sample divider, one part of the samples enters a laboratory to be tested, the other part of the samples is reserved, the samples needing sample reserving passes through the feeding system, and the PLC controls the samples to flow to the disc type sample box. The number of the turntables and the sample boxesare determined according to the working requirements and the specified sample reserving time. Feeding, sample reserving, material discarding and conveying processes are all controlled and completed through the PLC system, the whole process is of a closed loop type, and the sustainable assembly line operation is achieved. The automation technology is improved, the working efficiency is improved, the labor intensity is reduced, and manual control factors are eradicated.

Description

technical field [0001] The invention relates to the field of food processing, in particular to an equipment system and method for automatically retaining samples for food testing. Background technique [0002] After the grain test is completed, the sample needs to be reserved. Generally, the sample will be divided into two parts, one for testing, and the other for retaining the sample. Compare the initial inspection to see if there is any gap; second, if the customer raises an objection, you can provide the sample to the customer and keep the evidence for the batch of grain; third, supervise whether there are human factors in the initial inspection, etc. The current sample retention process needs to rely on manual work. The use of manpower to load samples, store samples, and discard samples is not only labor-intensive, but also the sample retention process is not standardized. At the same time, it takes up some unnecessary space. Unfortunately, the safety of samples cannot ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N35/00G01N1/02G05B19/05

CPCG01N35/00584G01N1/02G05B19/05

Inventor 高世军张建国张增臣郎咸芹刘彦龙张杰寇兴磊刘静

Owner SHANDONG SHOUGUANG JUNENG GOLDEN CORN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com