Electrical component reliability evaluation and service life prediction method

A technology for life prediction and components, used in environmental/reliability testing, instrumentation, electrical measurement, etc., to achieve the effect of shortening the test cycle, evaluating and predicting the results accurately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

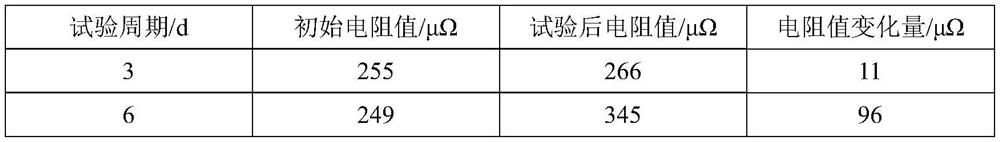

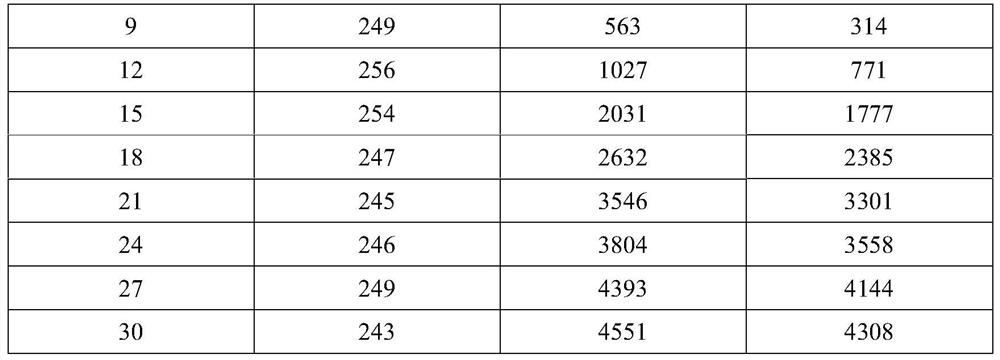

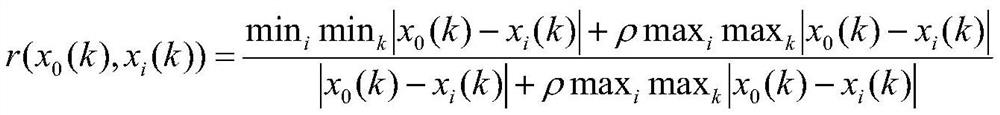

[0022] The present invention mainly pays attention to the impact of the airtight corrosion environment on the reliability and life of electrical components. Considering that corrosion mainly affects the electrical performance of electrical components, a key electrical performance parameter is selected as the reliability of electrical components in the present invention. Basis for evaluation and life prediction. As a preferred embodiment of the electrical component reliability evaluation and life prediction method of the present invention, it specifically includes the following steps:

[0023] S1) Obtain initial information such as types, specifications and models of electrical components through manuals, certificates or nameplates, and at the same time obtain their working condition parameters such as current and voltage under quasi-operating conditions.

[0024] S2) Design the accelerated corrosion test parameters in a targeted manner, including the setting of the test temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com