Portable temperature controller calibration system based on oil tank

A thermostat and portable technology, applied in the field of calibration devices of main transformer thermostats, can solve the problems of low efficiency of single-person calibration, affecting the effect of automatic design of the instrument, and large workload, etc. Easy to carry and ensure reliable placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

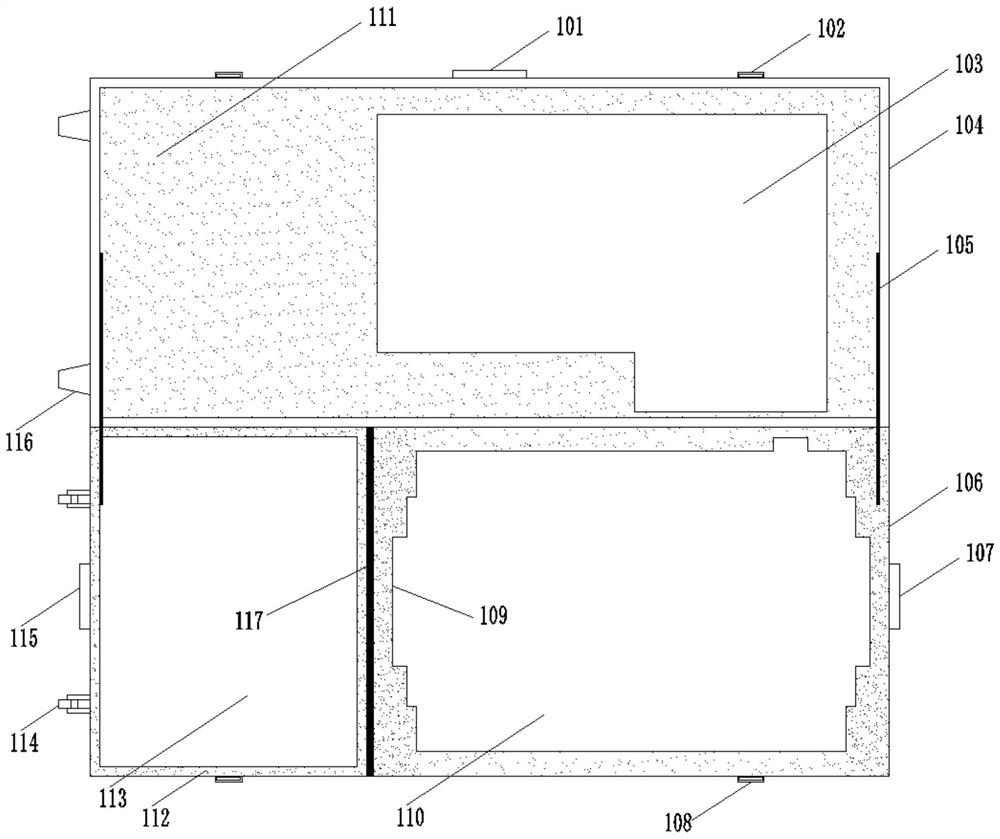

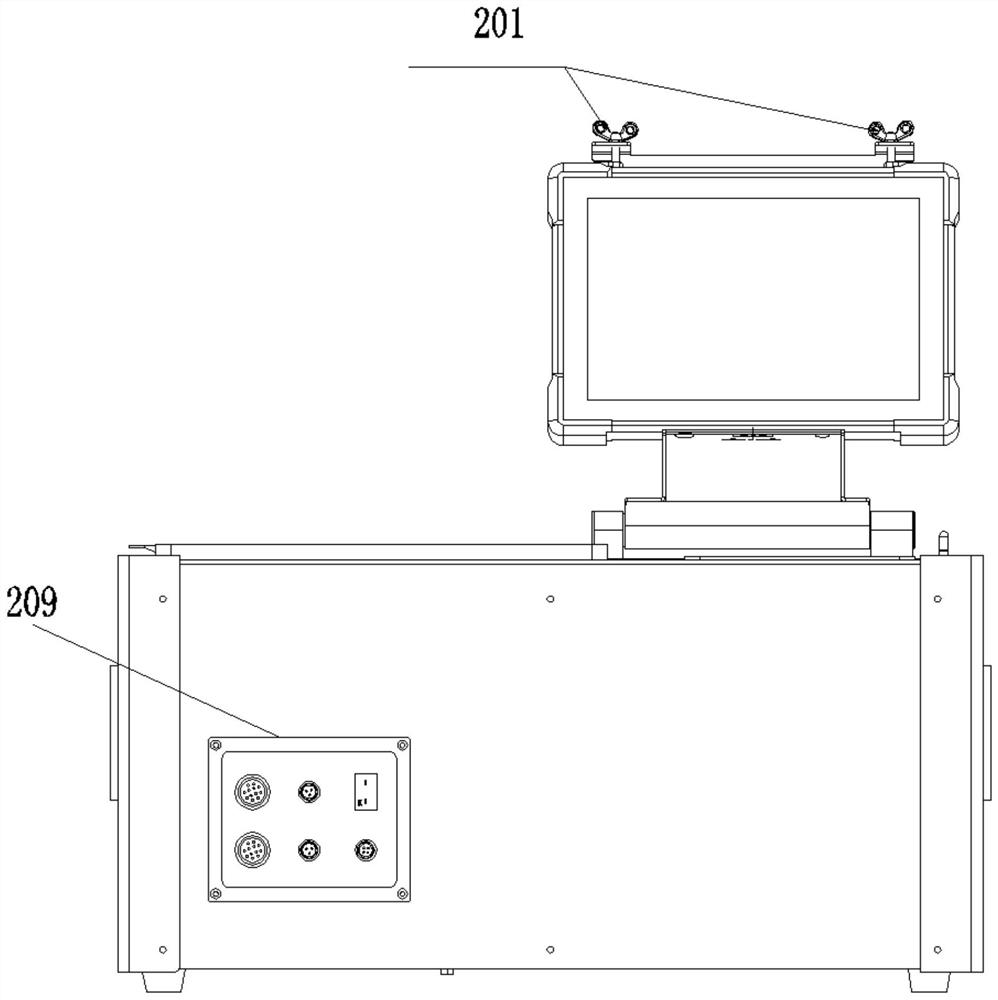

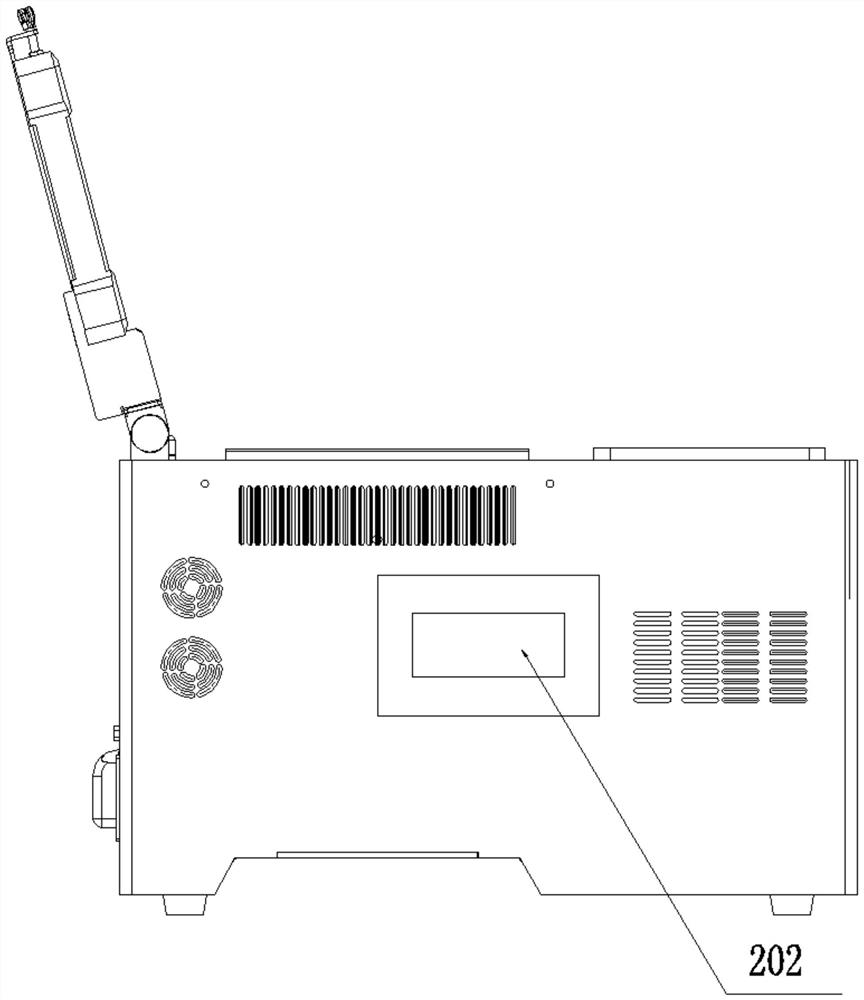

[0040] Such as Figure 1-10 As shown, it shows a specific embodiment of the present invention. As shown in the figure, the portable thermostat verification system based on the oil tank of the present invention includes a box assembly, and the box assembly includes a lower box 106 and a Close and open the upper cover 104 of the lower box; the lower box is provided with a partition 117, the left side of the partition is the camera assembly positioning groove 113, and the right side of the partition is the temperature control calibration host positioning groove 110; the camera assembly positioning The groove wall of the positioning groove of the tank and the temperature control verification host is filled with buffer cotton 112; the bottom of the upper cover is provided with two supporting feet 116, and the bottom of the lower box is provided with two walking wheels 114 at a position away from the upper cover; The cover is equipped with supporting feet, which are supported by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com