Production method for gas sensor element

A technology of gas sensor and manufacturing method, which is applied in the direction of instruments, scientific instruments, electrochemical variables of materials, etc., and can solve problems that do not mention the physical properties of geometric shapes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

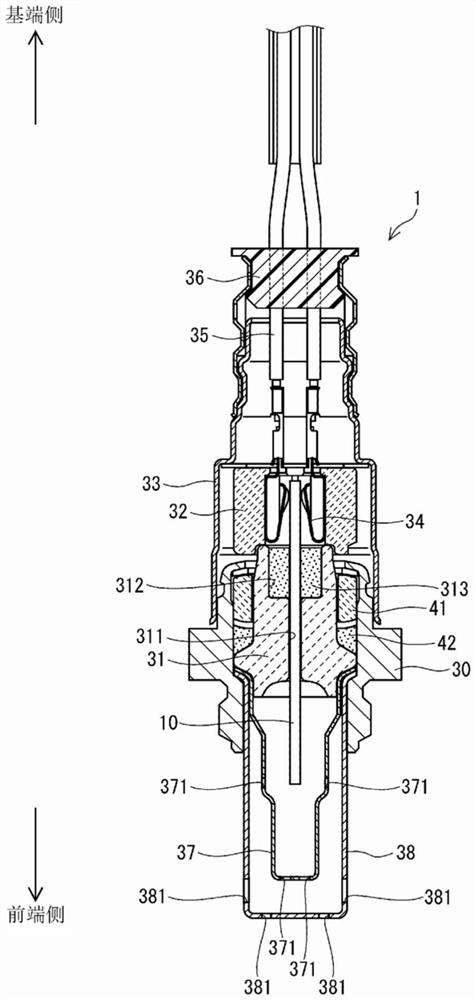

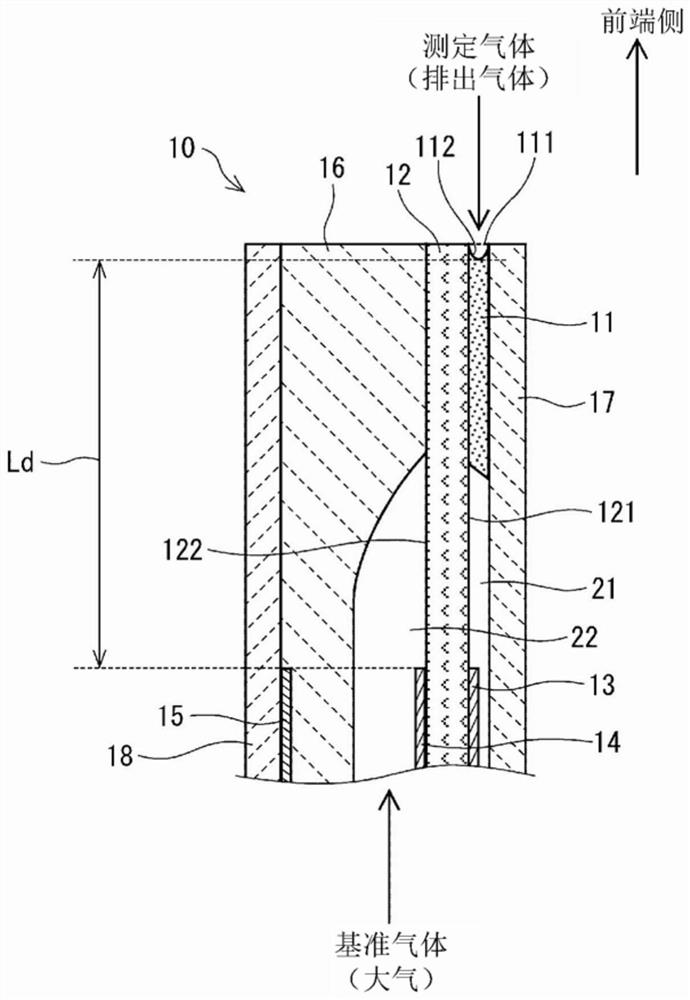

[0022] Hereinafter, a method of manufacturing a gas sensor element will be described based on the drawings. Such as figure 1 As shown, the gas sensor 1 according to one embodiment includes: a gas sensor element 10, a housing 30, a first insulator 31, a second insulator 32, a cover 33, a contact terminal 34, a lead wire 35, a bushing 36, an inner cover 37, And the outer cover 38 and the like. In the present embodiment, the gas sensor 1 is arranged in an exhaust pipe of a vehicle (not shown), and is used to detect the air-fuel ratio of the internal combustion engine by detecting the oxygen concentration in exhaust gas as a detection gas using the atmosphere as a reference gas. exist figure 1 In , the upper side of the paper is referred to as the base end side, and the lower side of the paper is referred to as the distal end side.

[0023] The casing 30 is attached to a not-shown exhaust pipe. The first insulator 31 is disposed radially inside the casing 30 , and is held by t...

other Embodiment approach

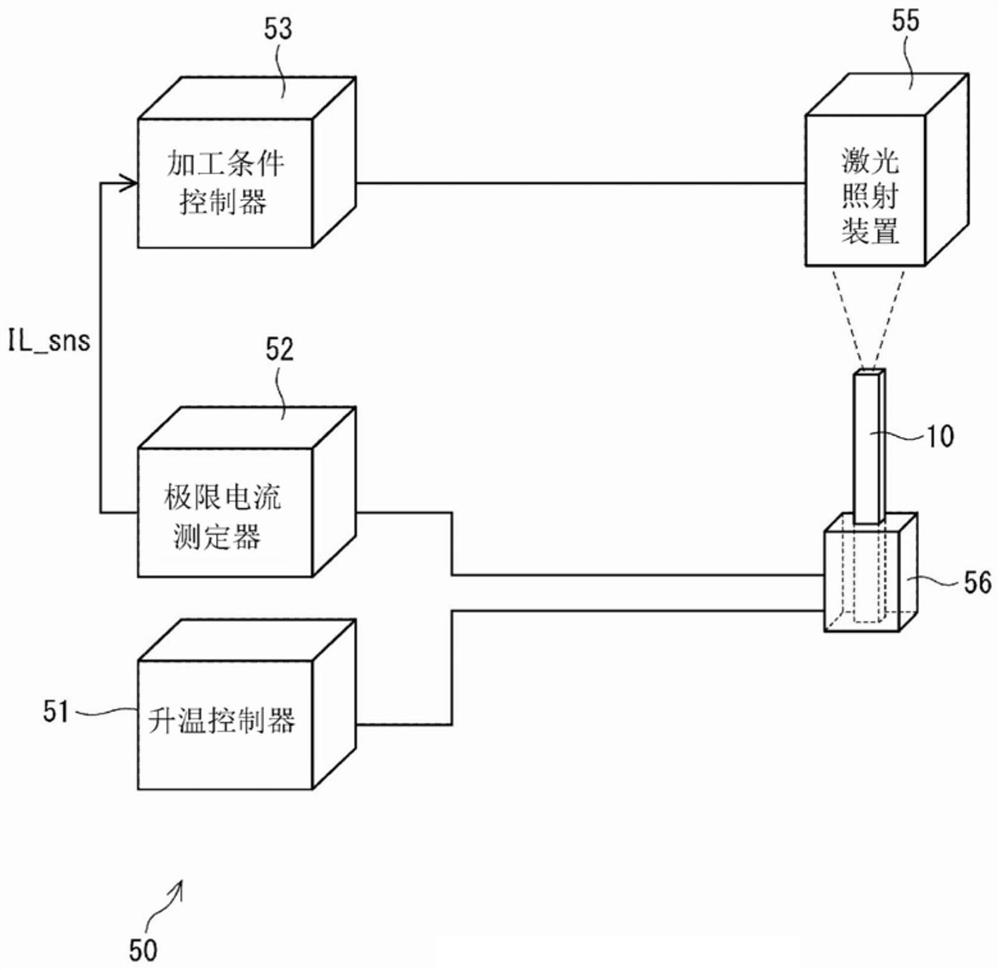

[0061] In the above embodiment, the diffusion resistance layer 11 is provided at the front end of the gas sensor element 10, and the diffusion distance Ld is adjusted by forming the concave portion 112 by ultrashort laser irradiation. In other embodiments, such as Figure 8 As shown, the diffusion distance Ld can also be adjusted by removing the entire front end surface 111 of the diffusion resistance layer 11 . That is, the front end surface of the processed diffusion resistance layer 11 may be planar. Additionally, if Figure 9 As shown, the diffusion distance Ld can also be adjusted by removing the outer peripheral side of the diffusion resistance layer 11 . That is, the front end surface of the processed diffusion resistance layer 11 may be convex. exist Figure 8 as well as Figure 9 In , descriptions other than the diffusion resistance layer 11, the solid electrolyte layer 12, the first electrode 13, and the first shielding layer 17 are omitted. Additionally, if ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com