Method for reducing blood waste after blood sampling by centrifugal bag type blood component separator

A blood component, centrifugal bag-type technology, applied in blood transfusion devices, suction devices, etc., can solve problems such as sensory discomfort, and achieve the effect of reducing discomfort, ensuring health, and scientific saline flushing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

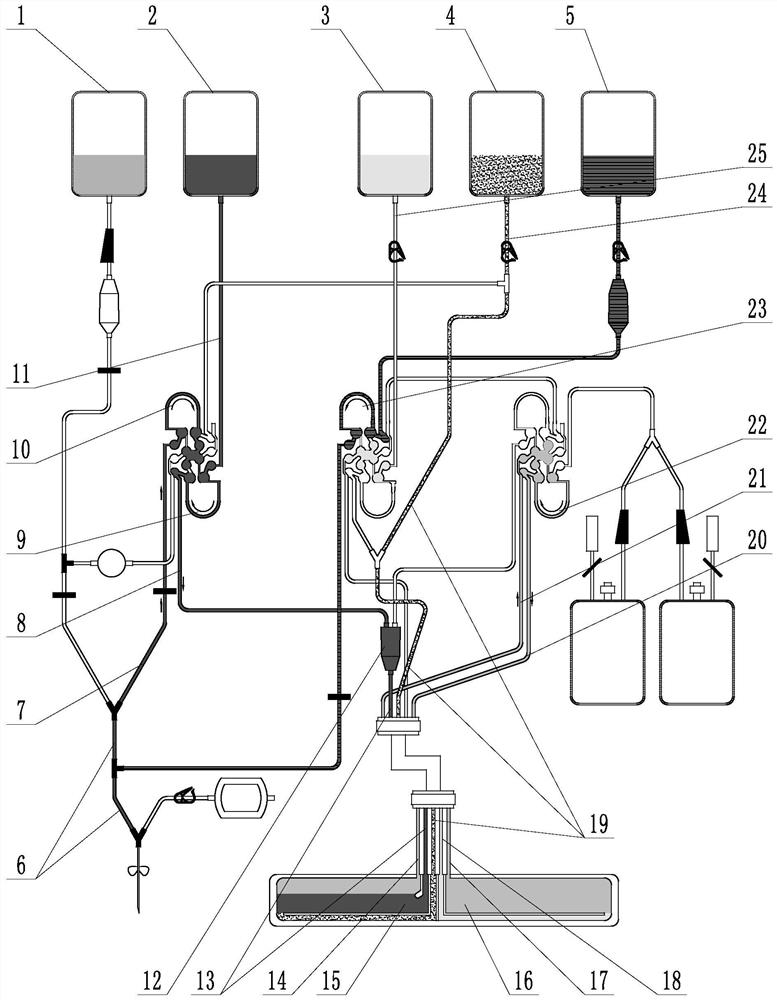

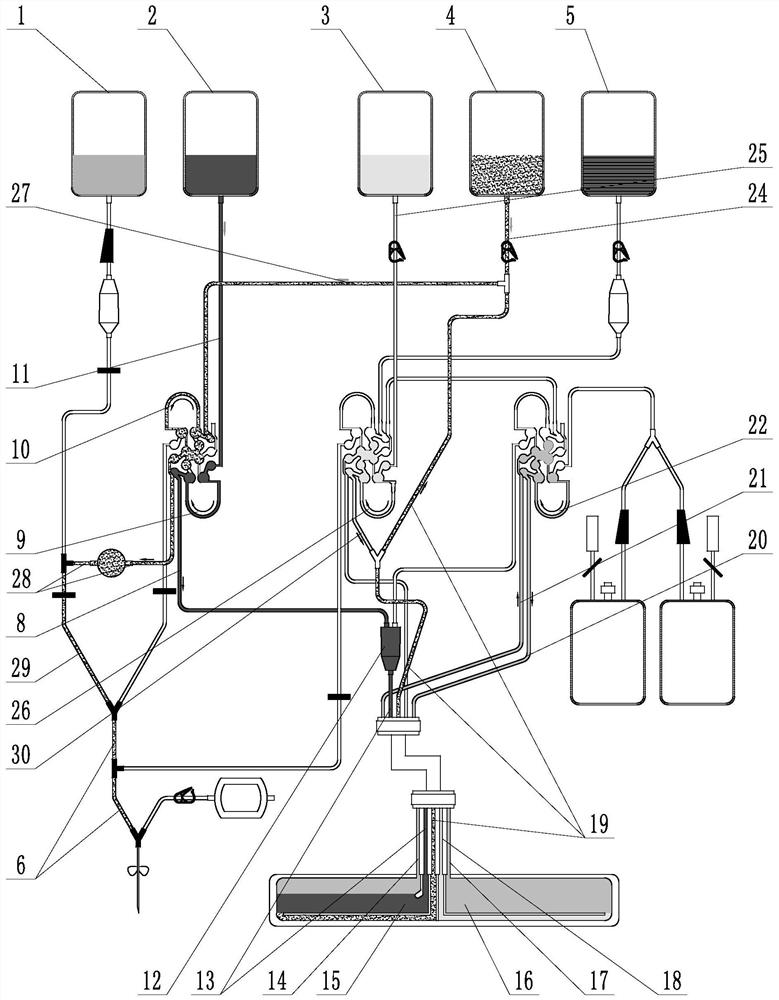

[0057] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

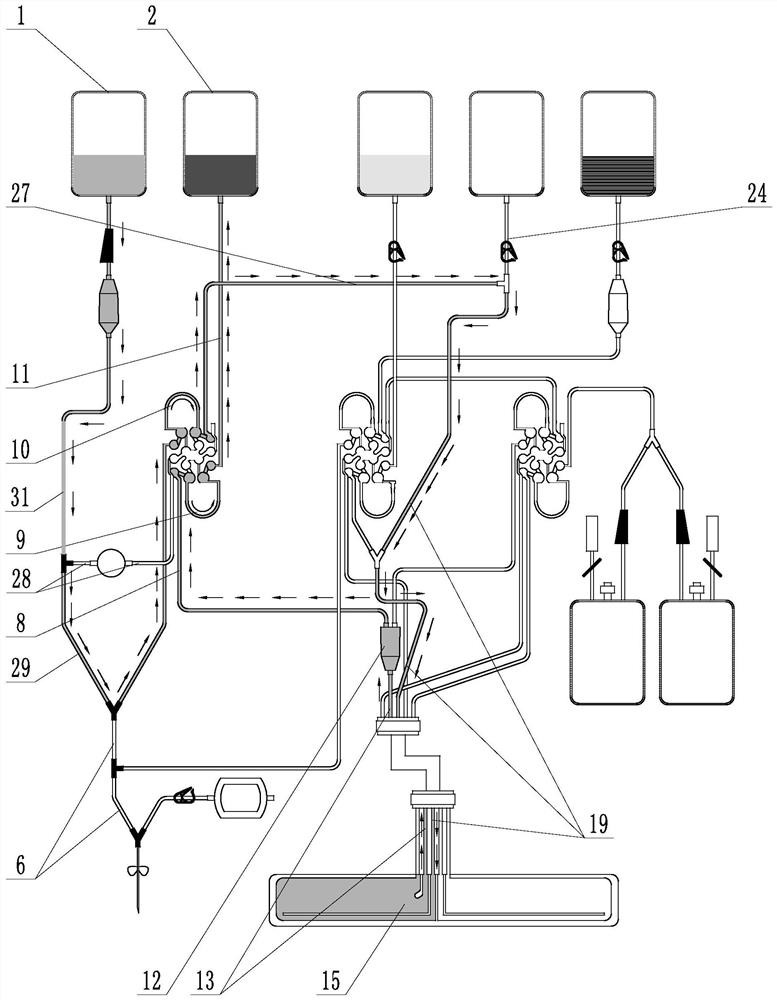

[0058] The method for reducing blood waste after blood collection by the centrifugal bag-type blood component separator according to the present invention is to wash the residual blood in part of the pipeline in the centrifugal bag-type blood component separator according to the following saline flushing process after the platelet collection is completed (specifically: Saline flushing procedure such as figure 1 shown):

[0059] Centrifugal pump 9 rotates counterclockwise, and blood collection pump 10 rotates clockwise at the same time. After the saline in saline bag 1 passes through saline bag connecting pipe 31, a part of it is sequentially flushed into return blood vessel 2 29 , inlet blood vessel 7 , pipeline 4 27 , and red blood cell delivery pipeline. 19. Bag body 15, centrifugal separation pipeline 13, retainer 12, pipeline 18, the residual blood in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com