Base material surface treatment method

A technology of substrate surface and treatment method, applied in special surfaces, pretreatment surfaces, devices for coating liquids on surfaces, etc., can solve problems such as difficult cleaning, product surface corrosion, strong acid and alkali, etc., to improve user experience , the effect of reducing the adhesion area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

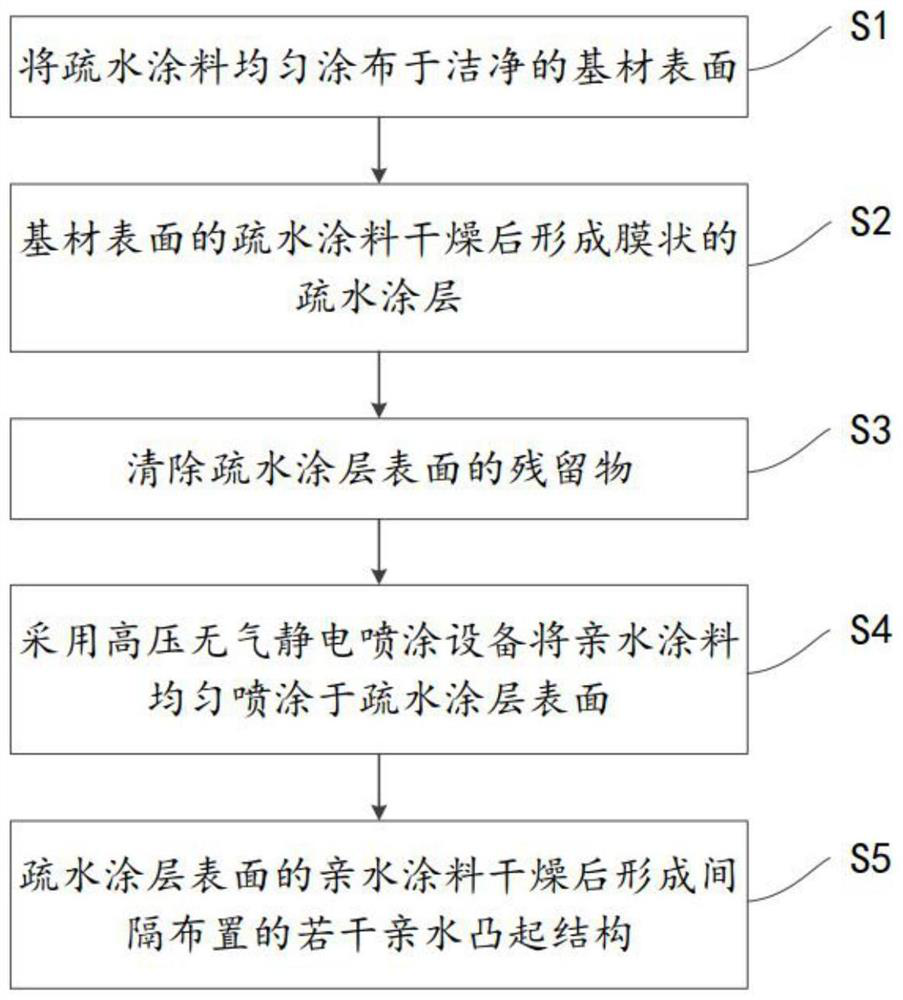

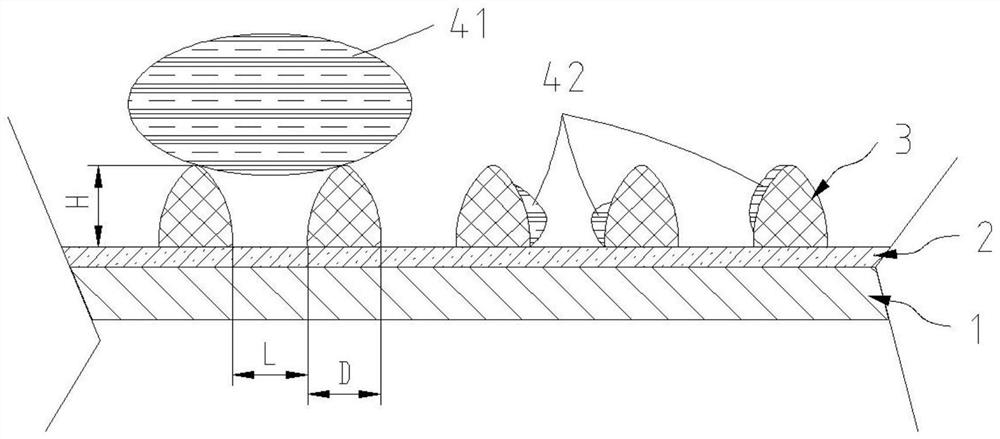

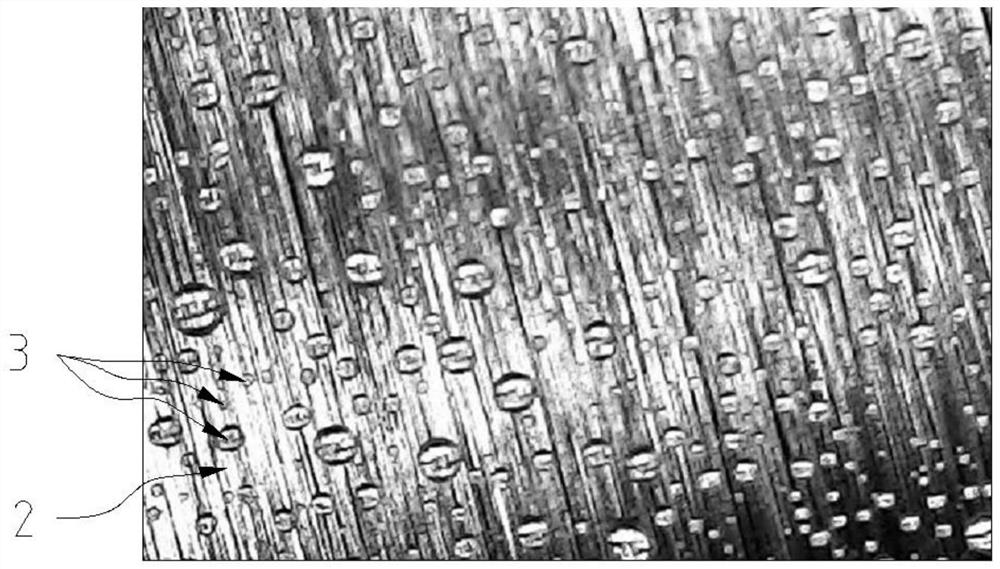

[0029] Such as Figure 1-3 As shown, the present embodiment provides a substrate surface treatment method, which includes steps:

[0030] S1: Evenly apply the hydrophobic coating on the surface of the clean substrate 1;

[0031] Specifically, first, use a cleaning agent to decontaminate the surface of the substrate 1 to be treated, for example, wipe with 99% alcohol, to remove the stains on the surface of the substrate 1 to be treated, and avoid affecting the hydrophobic coating due to dust and stains The film-forming effect and the smoothness after film-forming. Then, the hydrophobic coating is uniformly coated on the surface of the decontaminated substrate 1 .

[0032] S2: the hydrophobic coating on the surface of the substrate 1 is dried to form a film-like hydrophobic coating 2;

[0033] Specifically, in step S1, the hydrophobic coating is preferably a colored or colorless hydrophobic nano-coating that can dry at room temperature. After the hydrophobic nano-coating is c...

Embodiment 2

[0048] The difference between this embodiment and Example 1 is that the solid content and / or viscosity of the nano-hydrophilic coating (coating 4 cups) are different, and the size and / or water contact angle of the formed hydrophilic raised structure 3 are different .

[0049] In the embodiment, the electrostatic voltage of the high-pressure airless electrostatic spraying equipment is 65KV, the atomization air pressure is 0.5Mpa, and the spray air pressure of the nano-hydrophilic coating is 0.4Mpa. The solid content of the nano-hydrophilic coating is 11.5%, and the viscosity (coated with 4 cups) is 29s. When the spraying time is 2s, the water contact angle of the hydrophilic raised structure 3 is 145 degrees; when the spraying time is 3s, the water contact angle of the hydrophilic raised structure 3 is 158 degrees; when the spraying time is 4s, the hydrophilic raised structure 3 The water contact angle of the water protruding structure 3 is 163 degrees; when the spraying time ...

Embodiment 3

[0051] The difference between this embodiment and Example 1 is that the solid content and / or viscosity of the nano-hydrophilic coating (coating 4 cups) are different, and the size and / or water contact angle of the formed hydrophilic raised structure 3 are different .

[0052] In the embodiment, the electrostatic voltage of the high-pressure airless electrostatic spraying equipment is 65KV, the atomization air pressure is 0.5Mpa, and the spray air pressure of the nano-hydrophilic coating is 0.4Mpa. The solid content of the nano-hydrophilic coating is 11.5%, and the viscosity (coated with 4 cups) is 30s. When the spraying time is 2s, the water contact angle of the hydrophilic raised structure 3 is 141 degrees; when the spraying time is 3s, the water contact angle of the hydrophilic raised structure 3 is 155 degrees; when the spraying time is 4s, the hydrophilic raised structure 3 The water contact angle of the water protruding structure 3 is 162 degrees; when the spraying time ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com