Polymer composite stainless steel 3D printing material, preparation method and preparation method of part

A 3D printing, stainless steel technology, applied in the field of 3D printing of metal parts, can solve the problems of expensive printing equipment, harmful to the health of operators, and potential safety hazards, so as to save the cycle and cost of mold opening, less environmental pollution, and low maintenance costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment 1 discloses a method based on fused deposition modeling (FDM) technology, using polymer composite stainless steel 3D printing materials to prepare metal parts, the specific process is as follows:

[0039] A1: Put the stainless steel powder and the polymer binder at a volume ratio of 1.5:1 in a high-speed mixer and mix evenly, while heating while mixing, the heating temperature is 162°C-165°C, the mixing time is 160min, and then cooled to room temperature to obtain Polymer clad stainless steel mixture;

[0040] The stainless steel powder is made by mixing the following components by mass percentage:

[0041] Cr: 17.2%, Ni: 5.4%, Cu: 3.3%, Nb: 0.17%, Si: 0.64%, Fe: 73.29%;

[0042] The median particle size of the stainless steel powder is 8 μm, the bulk density is 40%, the tap density is 55%, and the powder particles are spherical or nearly spherical;

[0043] The polymer binder is made by mixing the following components by mass percentage:

[0044] Pol...

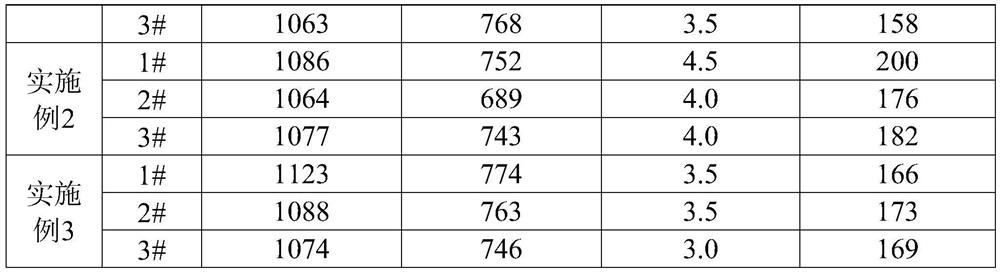

Embodiment 2

[0056] The second embodiment discloses a method for preparing metal parts based on fused deposition modeling (FDM) technology using polymer composite stainless steel 3D printing materials. The specific process is as follows:

[0057] B1: Put stainless steel powder and polymer binder at a volume ratio of 1.6:1 in a high-speed mixer and mix evenly, while heating while mixing, the heating temperature is 167°C-172°C, the mixing time is 150min, and then cooled to room temperature to obtain Polymer clad stainless steel mixture;

[0058] The stainless steel powder is made by mixing the following components by mass percentage:

[0059] Cr: 16.1%, Ni: 4.3%, Cu: 4.0%, Nb: 0.26%, Si: 0.62%, Fe: 74.72%;

[0060] The median particle size of the stainless steel powder is 8 μm, the bulk density is 45%, the tap density is 66%, and the powder particles are spherical or nearly spherical;

[0061] The polymer binder is made by mixing the following components by mass percentage:

[0062] Polyo...

Embodiment 3

[0074] This embodiment three discloses a method for preparing metal parts based on fused deposition modeling (FDM) technology using polymer composite stainless steel 3D printing materials. The specific process is as follows:

[0075] C1: Mix stainless steel powder and polymer binder in a high-speed mixer at a volume ratio of 1.8:1, and heat while mixing. The heating temperature is 175°C-180°C, the mixing time is 120min, and then cooled to room temperature to obtain Polymer clad stainless steel mixture;

[0076] The stainless steel powder is made by mixing the following components by mass percentage:

[0077] Cr: 15.6%, Ni: 5.8%, Cu: 4.8%, Nb: 0.43%, Si: 0.66%, Fe: 72.71%;

[0078] The median particle size of the stainless steel powder is 8 μm, the bulk density is 50%, the tap density is 78%, and the powder particles are spherical or nearly spherical;

[0079] The polymer binder is made by mixing the following components by mass percentage:

[0080] Polyoxymethylene: 35.5%, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com