Hydraulic buffer hinge assembling machine

A hydraulic buffer and assembly machine technology, applied in assembly machines, metal processing, metal processing equipment, etc., can solve the problems of increasing product failure rate, increasing overall parts stuck, and reducing work efficiency, so as to reduce labor The effect of the operations of assembling and inserting pins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. Terms such as "upper", "inner", "middle", "left", "right" and "one" quoted in this specification are only for the convenience of description, and are not used to limit the scope of the present invention. The scope of implementation and the change or adjustment of its relative relationship shall also be regarded as the scope of implementation of the present invention without substantive changes in technical content.

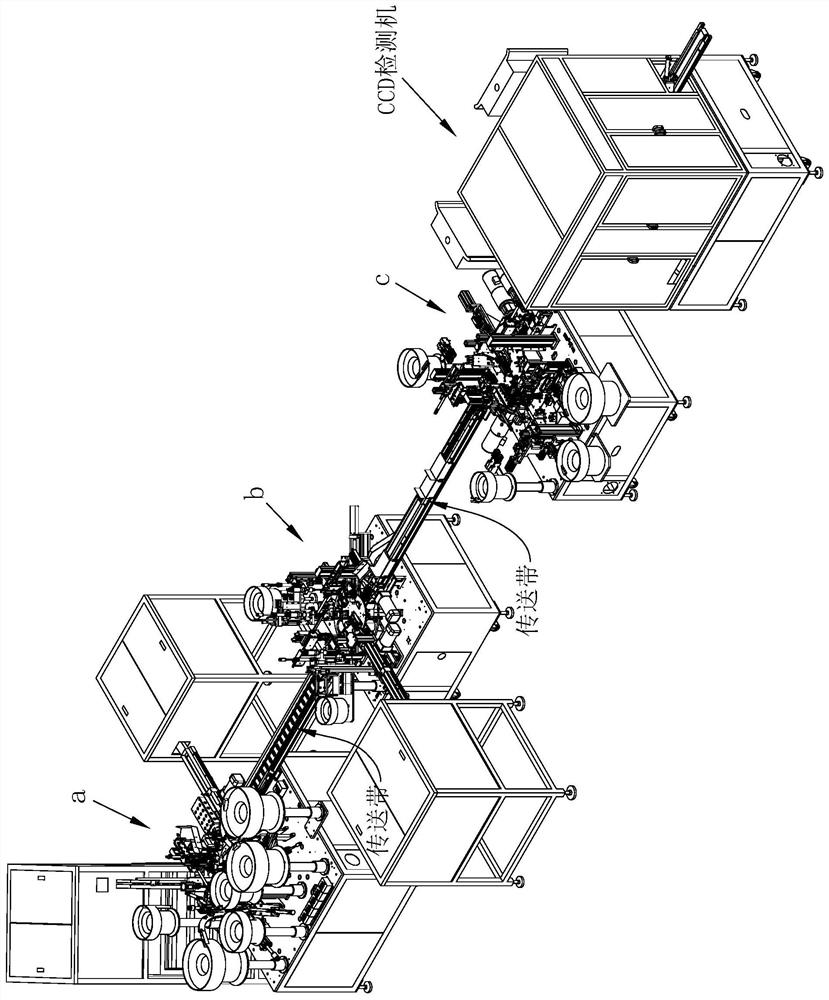

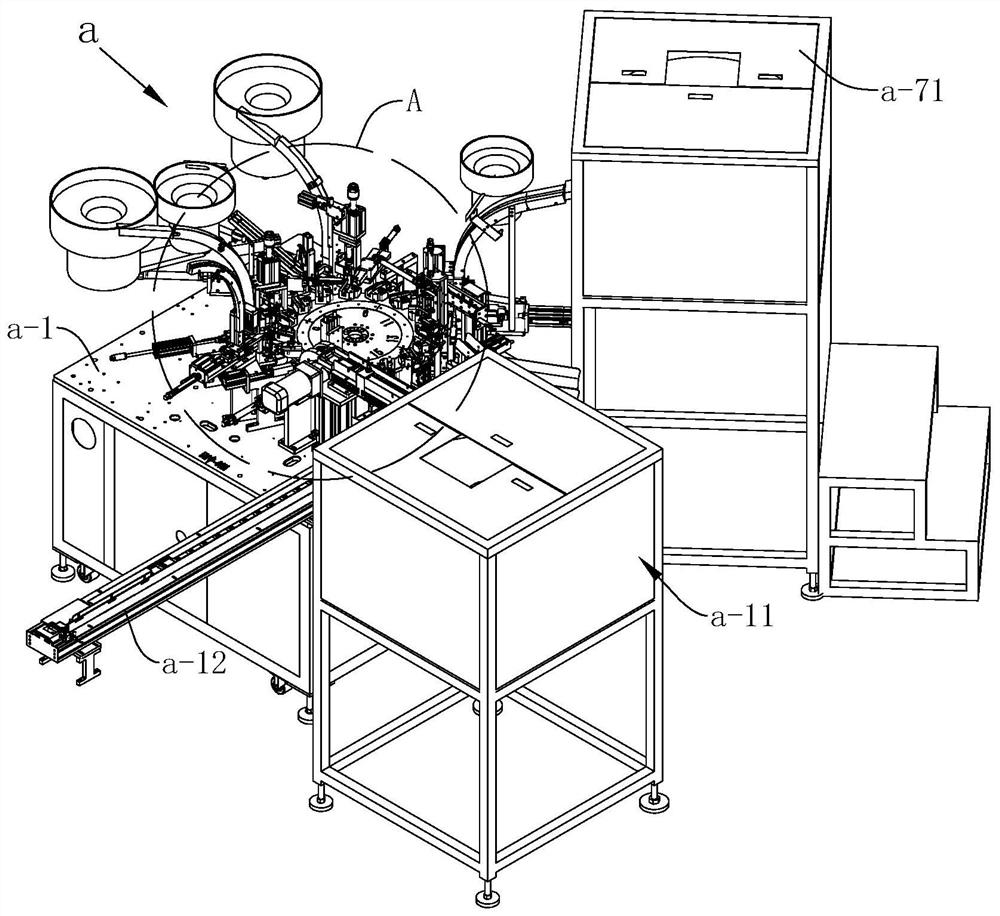

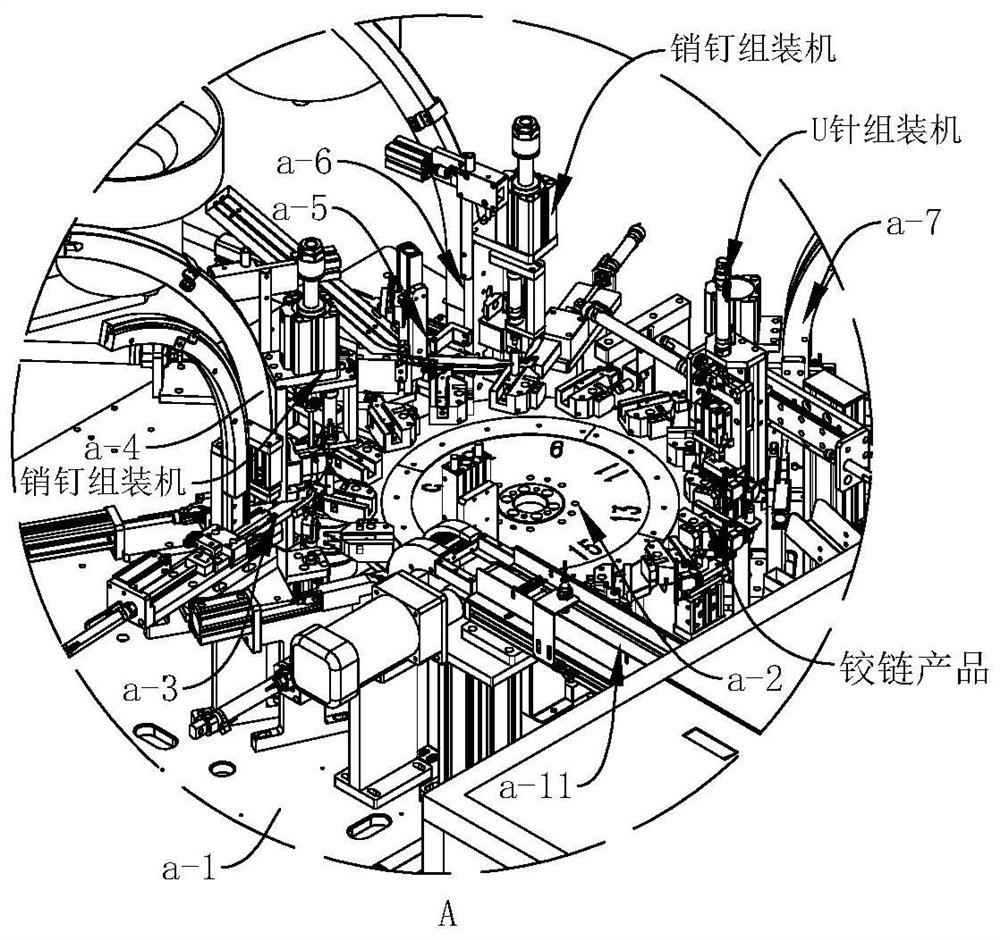

[0050] refer to figure 1 , figure 2 , Figure 17 with Figure 25 As shown, a hydraulic buffer hinge assembly machine includes an arm body assembly machine a for assembling the pocket and the arm body, a base assembly machine b for assembling the base, and an oil cylinder assembly machine c for assembling the oil cylinder.

[0051] refer to Figure 2 to Figure 5 As shown, the arm body assembly machine a includes a fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com