Novel multifunctional two-way chamfering machine and using method thereof

A multi-functional, chamfering machine technology, applied in the field of mechanical processing, can solve the problems of low processing efficiency, impact on processing accuracy, and impact on the health of equipment operators, and achieve the effects of improving work efficiency, improving product accuracy, and preventing hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

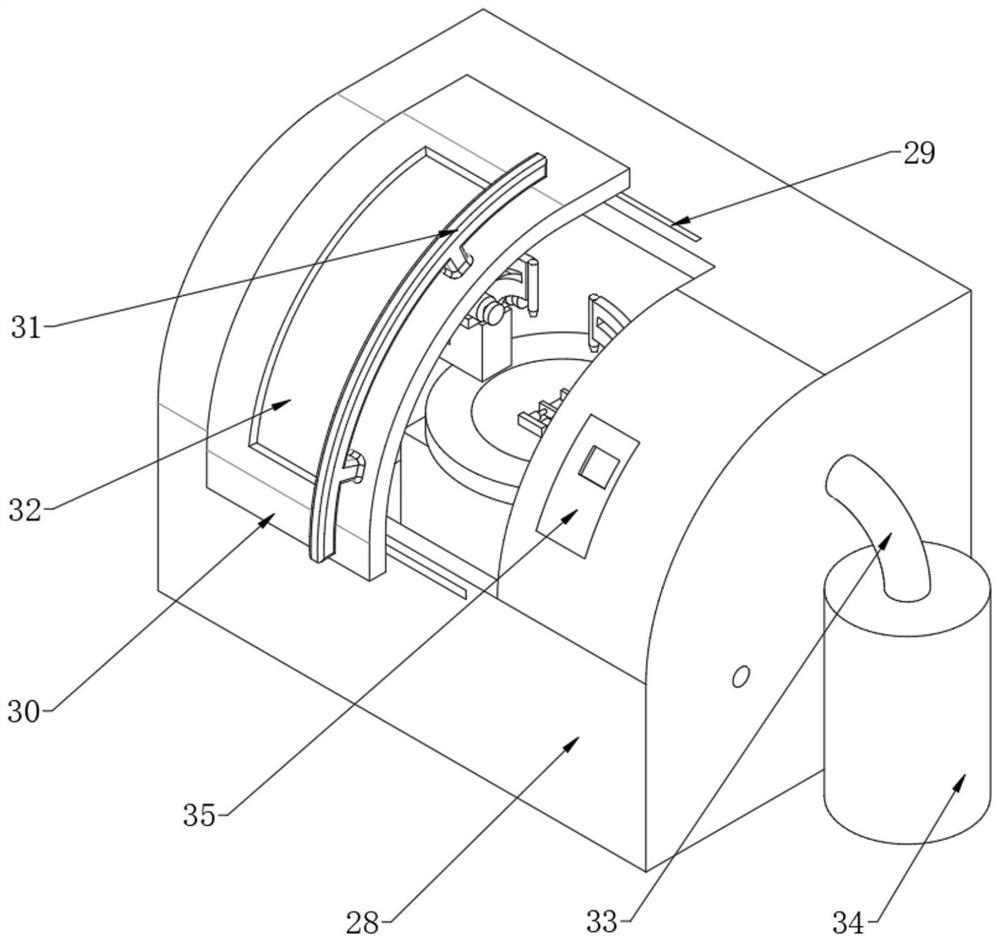

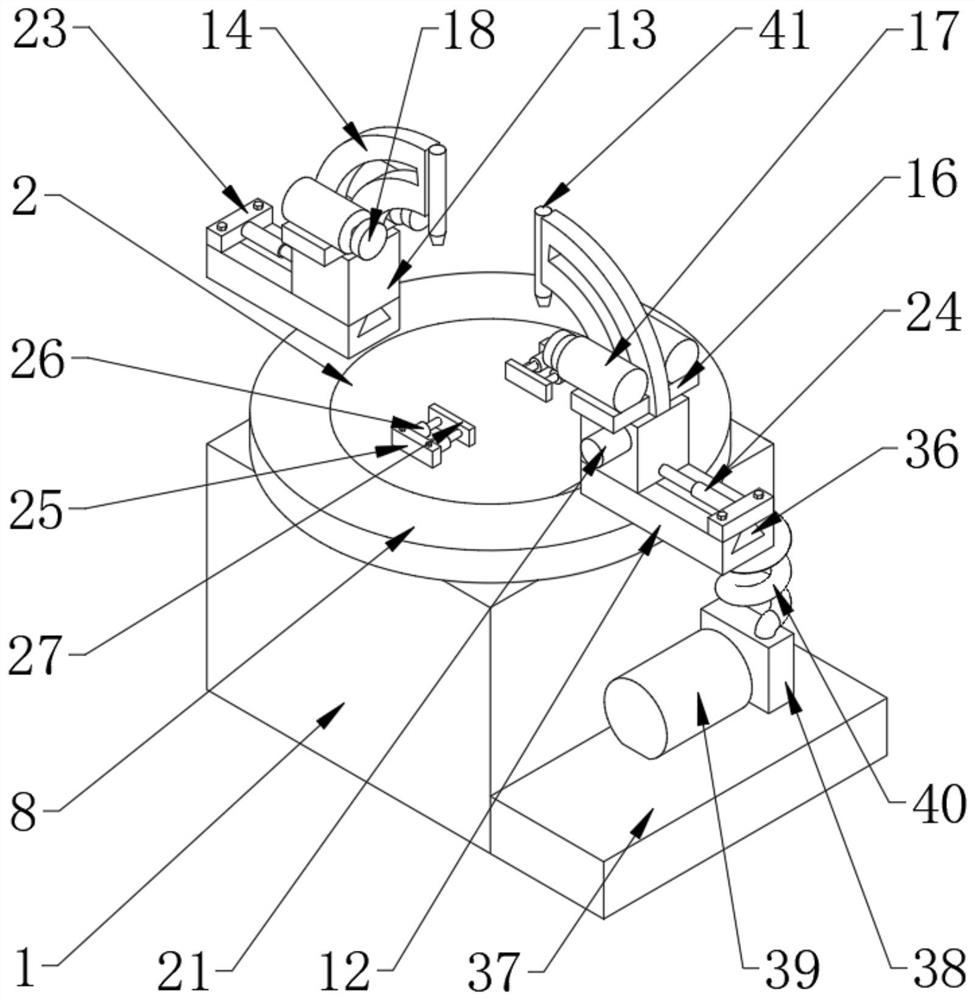

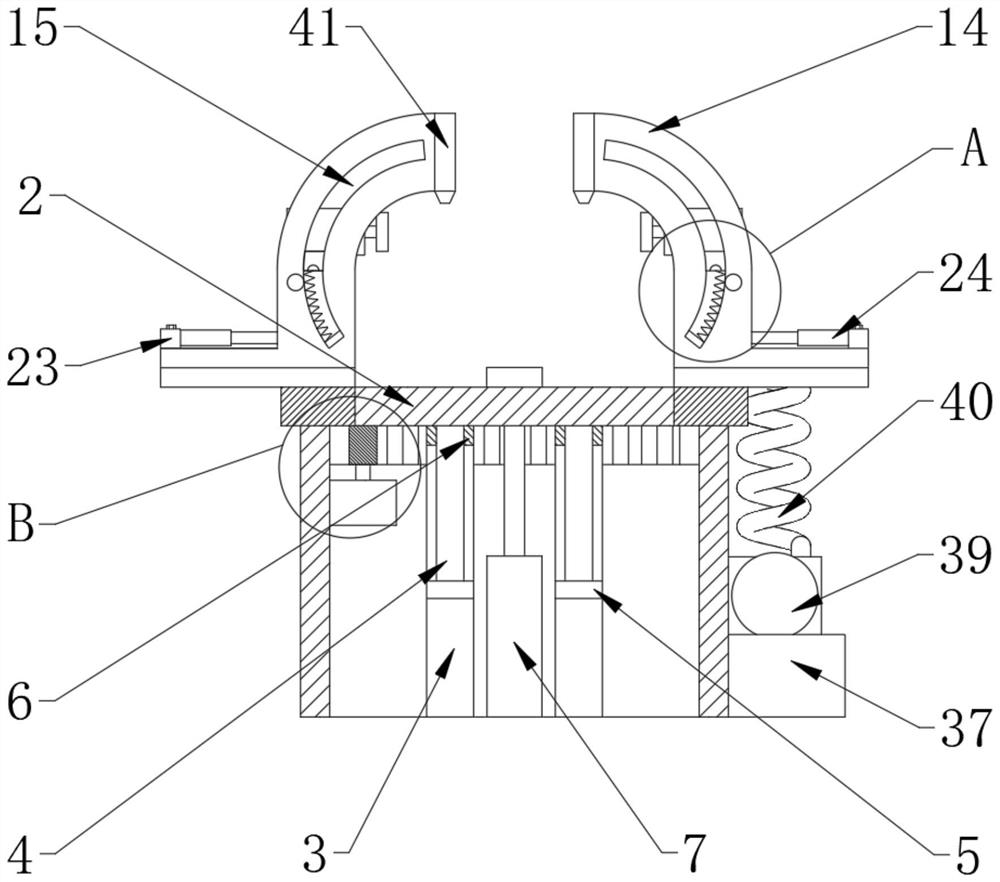

Embodiment 1

[0031] Such as Figure 1-5 As shown, a new multifunctional two-way chamfering machine and its use method include a base 1 and an operating table 2. The base 1 is a hollow cuboid structure inside the base 1. A hydraulic cylinder 7 is vertically fixed at the center of the inner bottom of the base 1. The hydraulic cylinder 7 The top output end is fixedly connected to the console 2, the inner bottom of the base 1 surrounds the hydraulic cylinder 7 and vertically fixes the support tube 3, the top of the support tube 3 fits closely with the console 2, and the top of the console 2 is symmetrically arranged with a second installation block 25 along the center , two second installation blocks 25 are fixedly installed on the opposite surface of the cylinder 26, the output end of the cylinder 26 is connected to the clamping block 27 by rotation, the bottom of the console 2 is located in the support tube 3 and the vertically fixed slide bar 4 is fixed, and the top of the base 1 is located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com