Oil pump assembling tool

A technology for assembling tooling and oil pumps, which is applied in the direction of manufacturing tools, workpiece clamping devices, and hand-held tools. It can solve the problems of clamping looseness and clamping damage to the outer surface of products, and achieves convenient press-fitting, small space occupation, and excellent structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

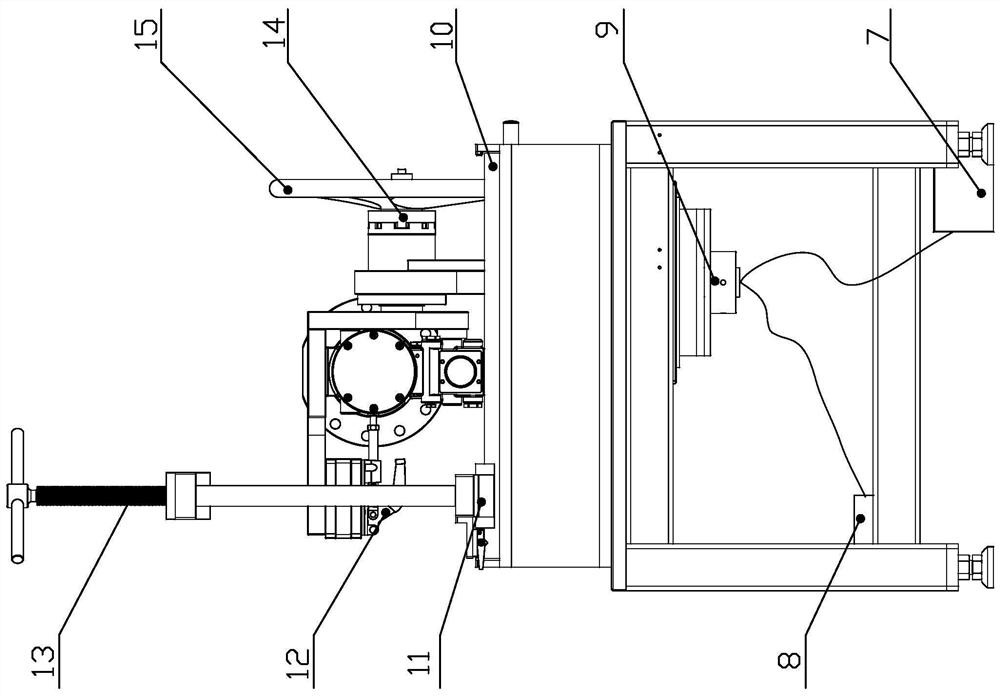

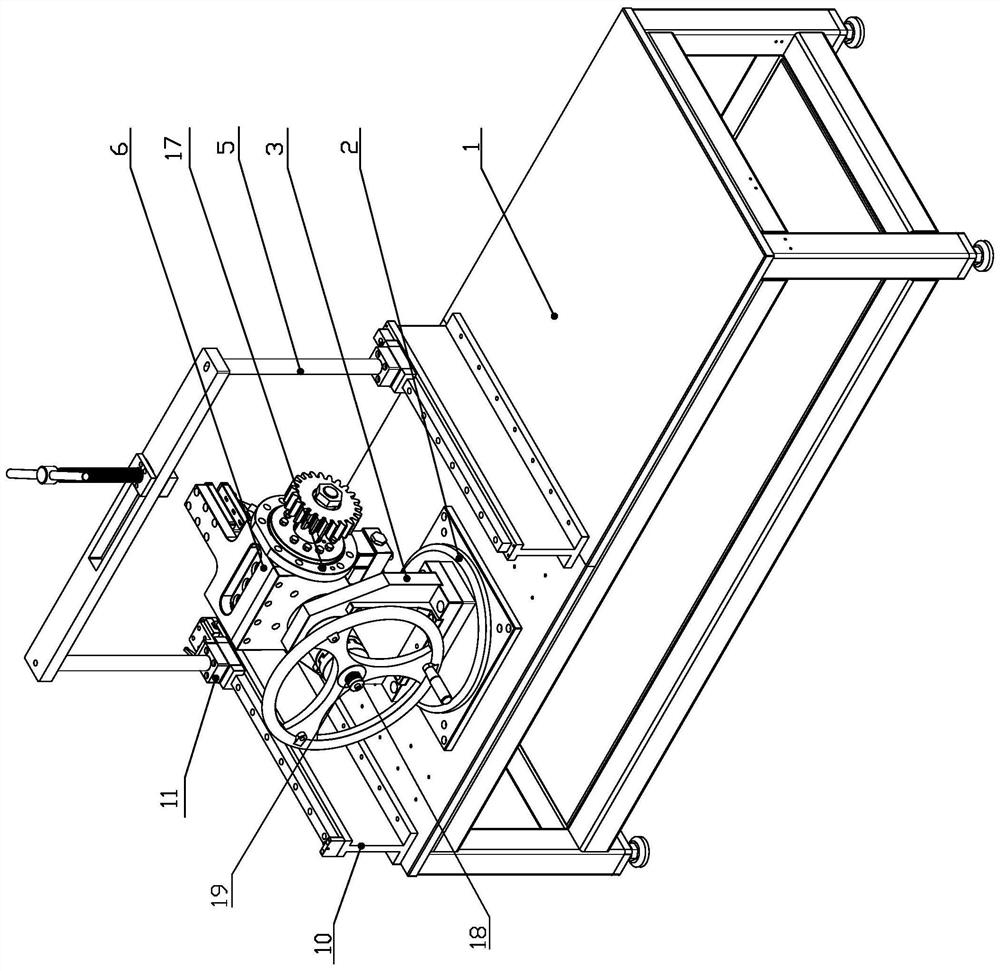

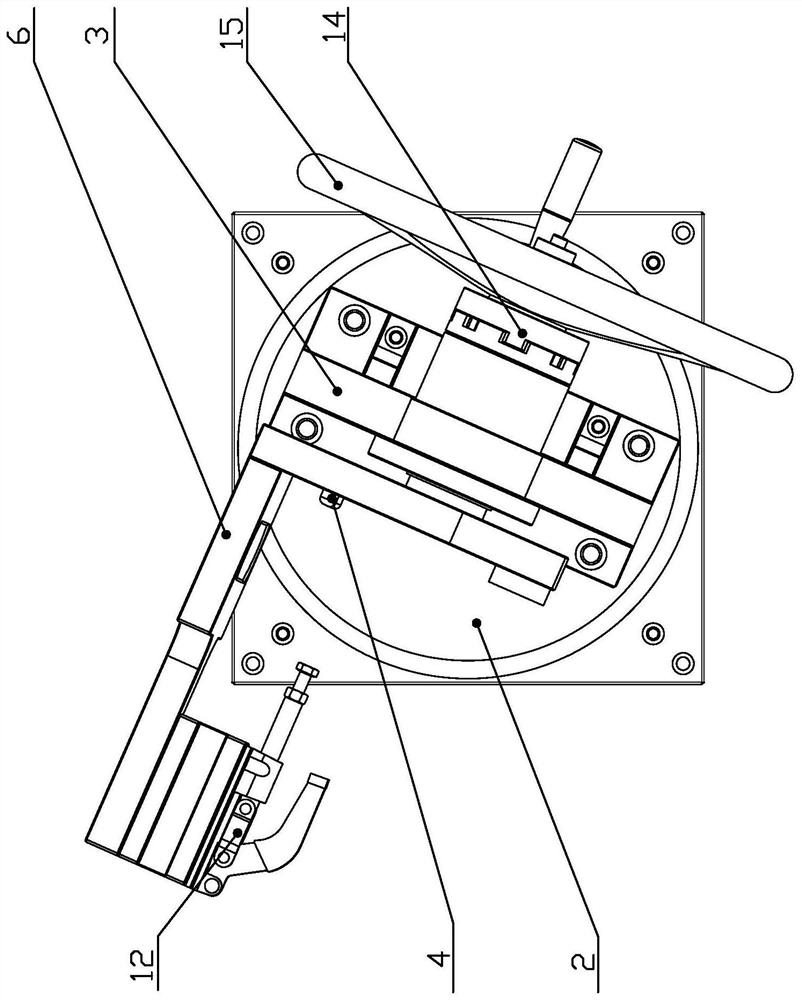

[0017] Figure 1-3 Including 1-table, 2-turntable, 3-stand, 4-positioning column, 5-gantry, 6-L-shaped bracket, 7-brake foot switch, 8-brake power supply unit, 9-brake Brake, 10-linear guide rail, 11-slider, 12-pump body fixed toggle clamp, 13-press fit screw, 14-graduating cylinder, 15-hand wheel, 16-transmission shaft, 17-pump body, etc.

[0018] Such as Figure 1-3 As shown, the present invention is an oil pump assembly tool, comprising a workbench 1, on which a turntable 2 is installed through bearing rotation, a brake brake 9 is installed in the middle of the workbench 1, and a brake foot switch 7 and a brake power supply are installed at the bottom of the workbench 1. The unit 8, the brake foot switch 7 and the brake power supply unit 8 are all connected to the brake brake 9 through wires, the lower end of the turntable 2 is located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com