Processing method of side-grooved thermal insulation board

A processing method and technology for thermal insulation boards, which are applied in the direction of building thermal insulation materials, thermal insulation, chemical instruments and methods, etc., can solve the problems of affecting the strength of the board body, inconvenient processing and production, and increasing the process, so as to increase the sealing package processing, increase the Insulation effect, increase the effect of waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

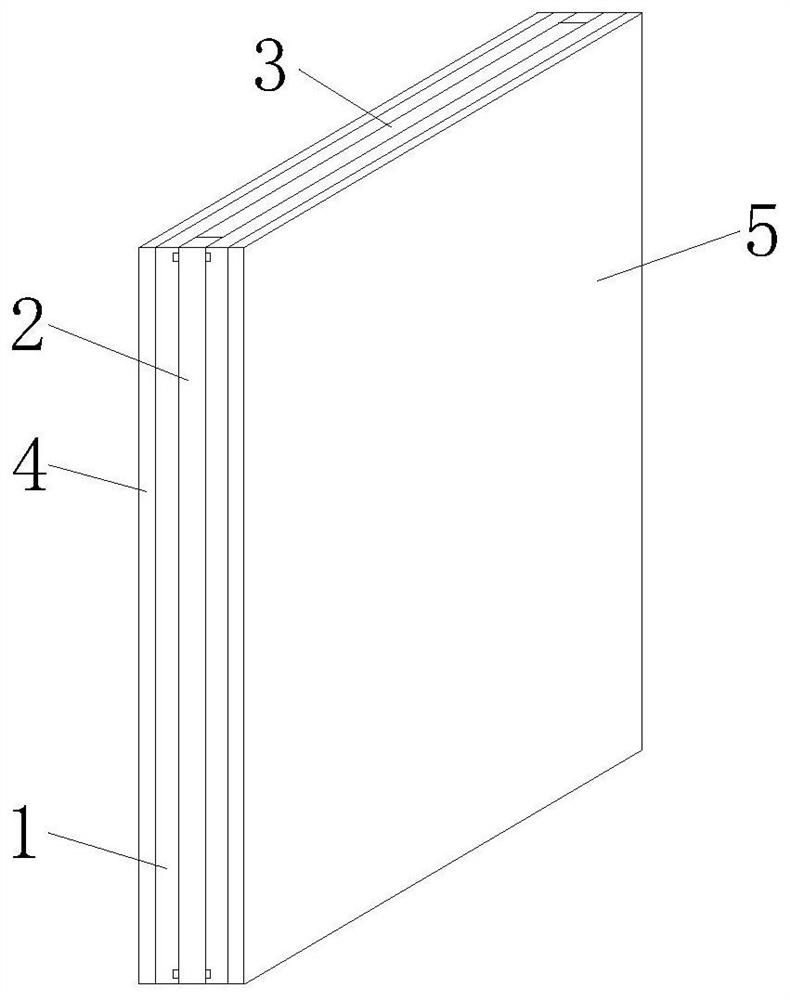

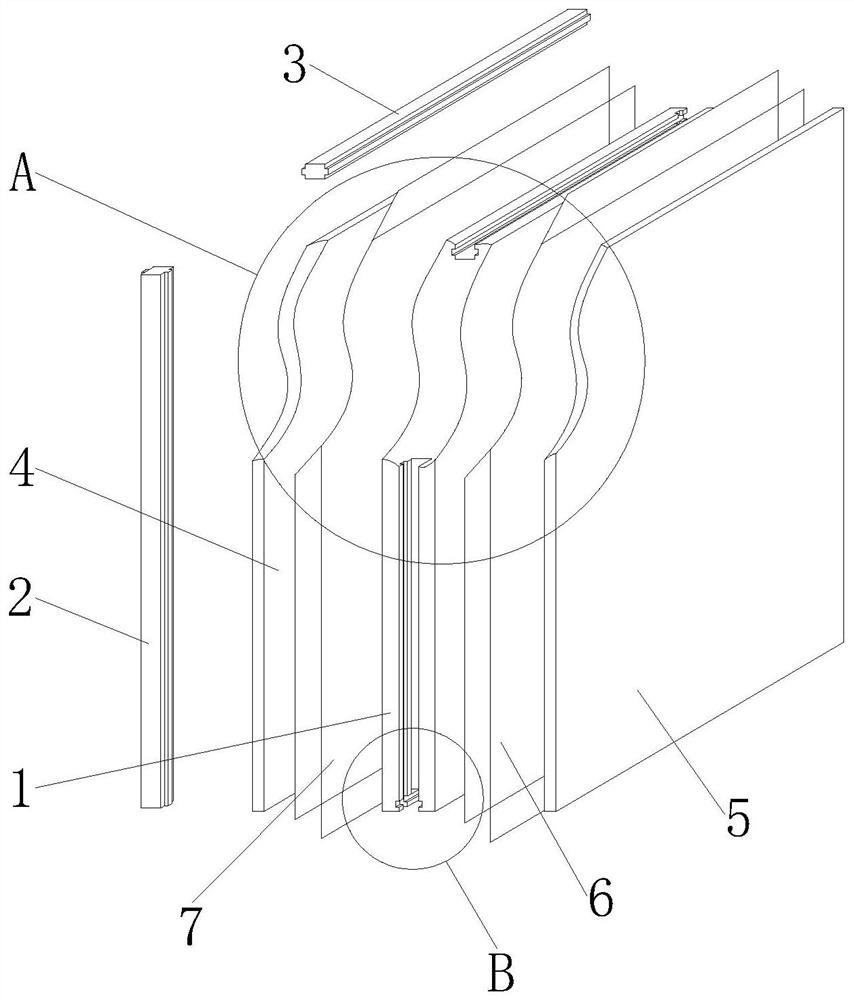

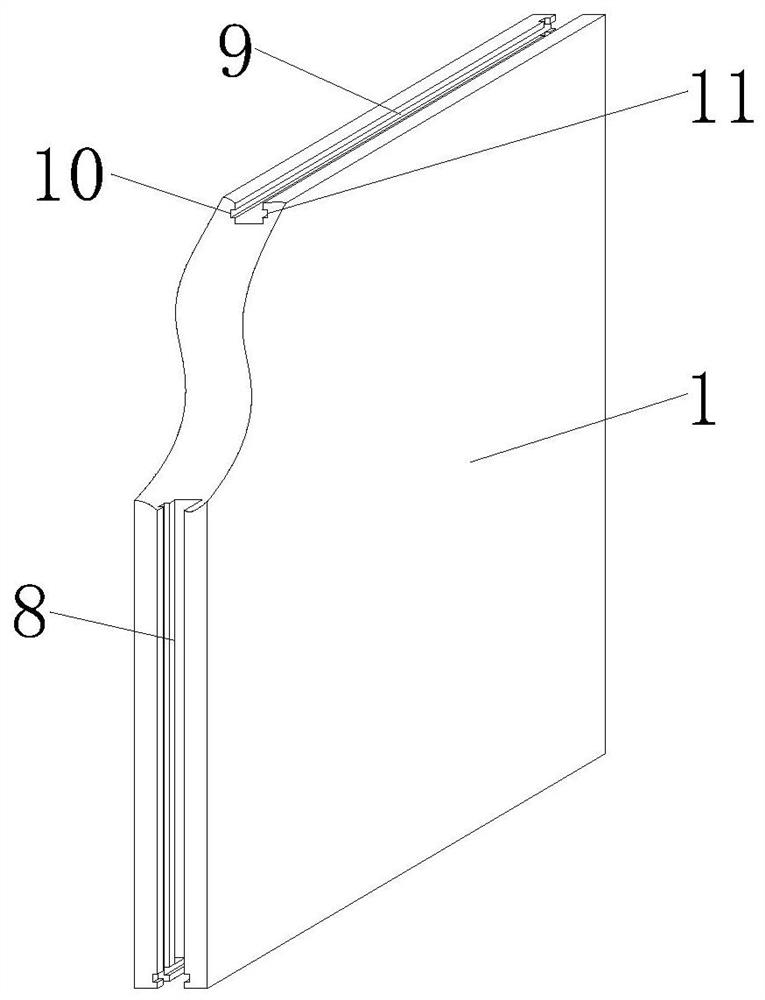

[0027] Such as Figure 1-6 As shown, a method for processing thermal insulation panels with side grooves, the specific steps are as follows:

[0028] Step 1: Raw material preparation: prepare rock wool board 1, and set short grooves 9 in the middle of the upper and lower sides, and long grooves 8 in the middle of the left and right sides; prepare inner waterproof cloth 6 and outer waterproof cloth of the same size. Tarp 7, and cut off four square corners at the four corners, so that the four sides of the inner tarpaulin 6 and the outer tarpaulin 7 all form a folding cloth 12; prepare two long clips 2 and two short clips 3; Prepare the outer edge board 4 and the inner edge board 5, the size of the rock wool board 1 is 80cm long, 80cm wide, and 2cm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com