Hoisting device for iron accessory galvanization

A hoisting device and iron accessory technology, applied in safety devices, transportation and packaging, hot dip plating process, etc., can solve the problems of low work efficiency, inconvenient use, high labor intensity, etc., to improve work efficiency, facilitate disassembly, The effect of reducing security risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

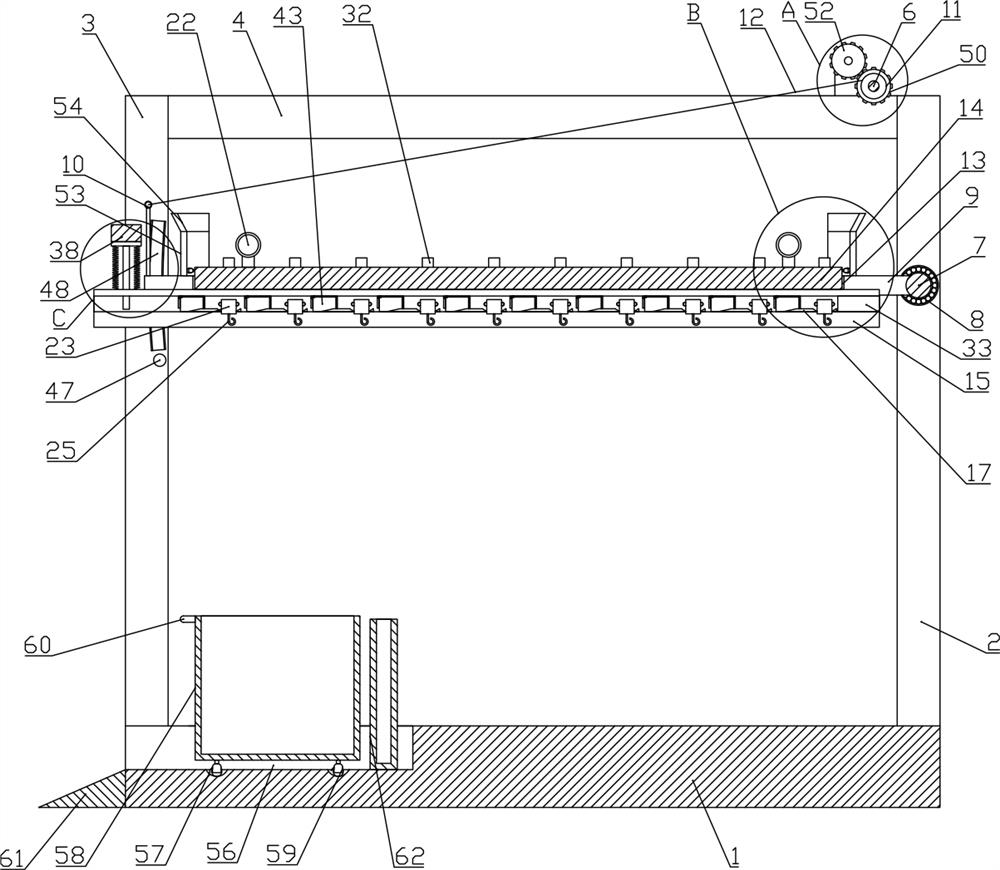

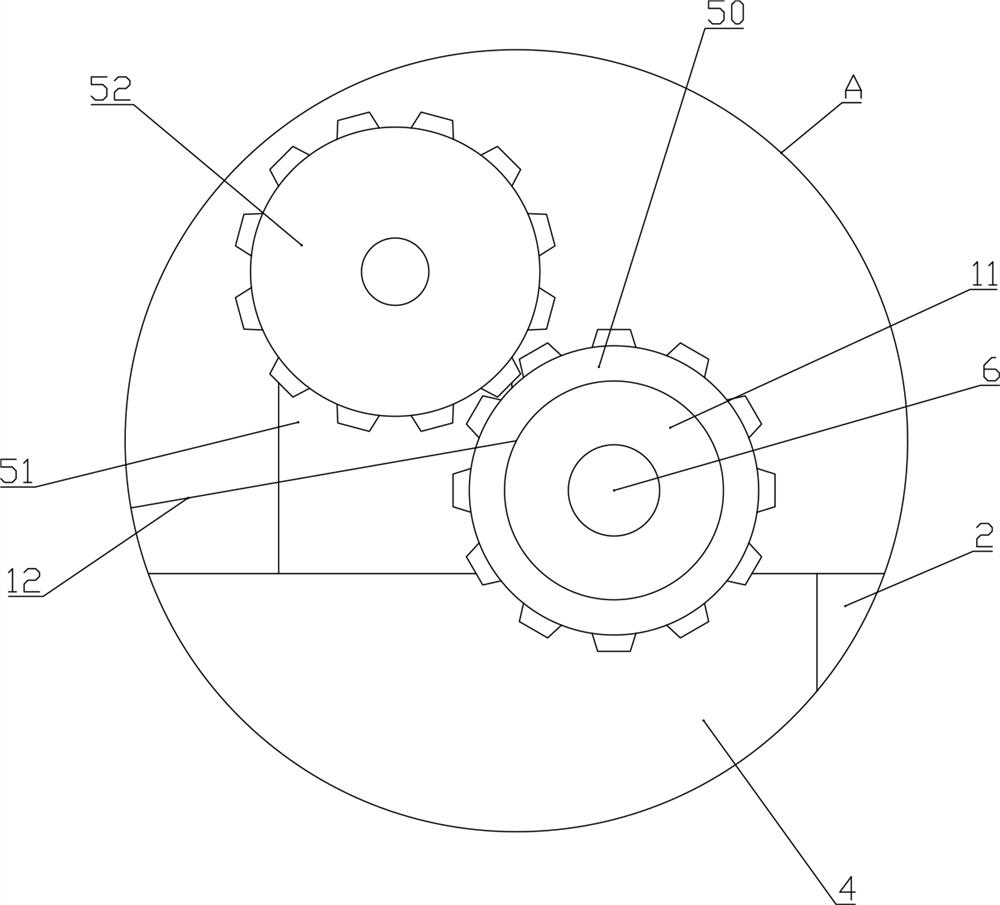

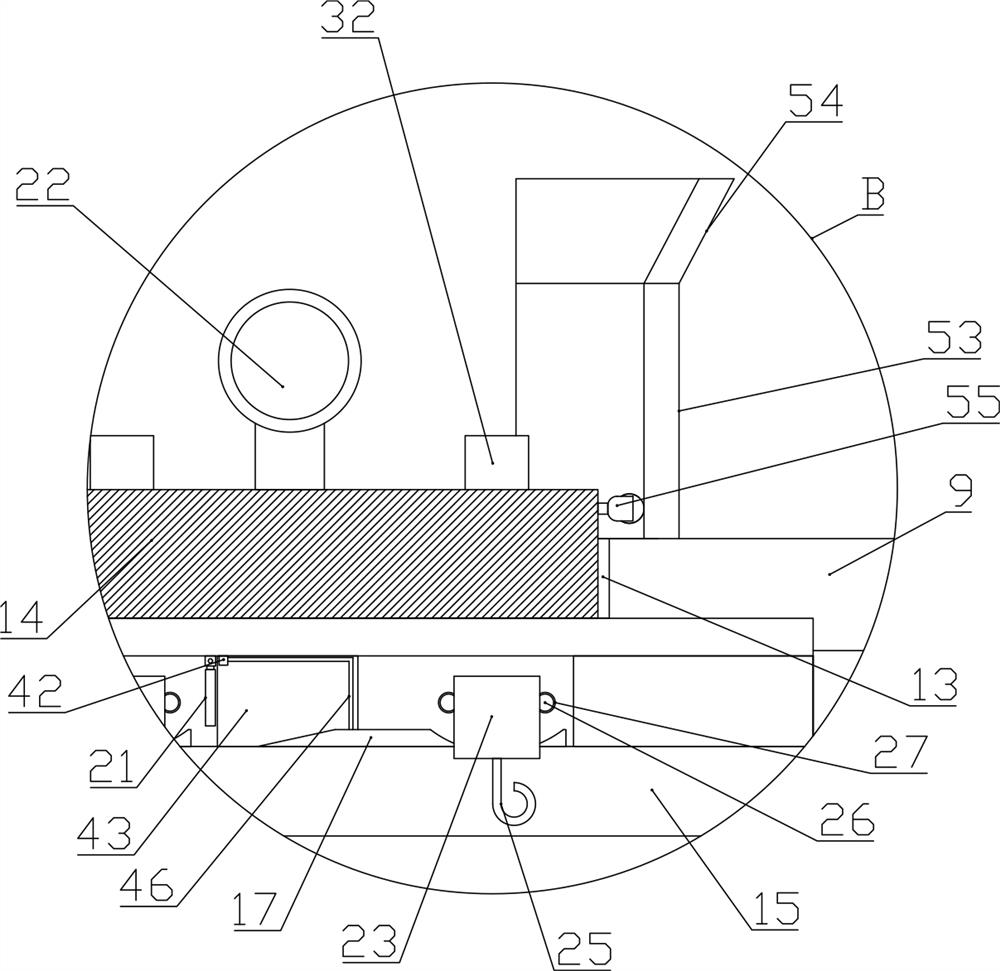

[0030] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-12 Shown: a hoisting device for galvanizing iron accessories, including a holding platform 1, a power mechanism is arranged above the holding platform 1, a guiding mechanism is arranged on one side of the driving mechanism, and a transfer mechanism is arranged on the side of the guiding mechanism. A positioning and holding mechanism is provided on the platform 1, and a hoisting mechanism is provided on one side of the positioning and holding mechanism.

[0031] The positioning holding mechanism includes a first supporting column 2 fixedly installed on the two ends of the rear side of the upper surface of the holding platform 1, and a second supporting column 3 is installed at the two ends of the front side of the upper surface of the holding platform 1, the first supporting column 2 and the second supporting column. The upper end of the supporting column 3 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com