Energy-saving water supply system and working method thereof

A water supply system and control system technology, applied in water supply pipeline systems, water supply devices, water supply devices, etc., can solve the problems of waste of fresh water resources, non-conformity, and inability to re-use drainage, so as to save fresh water waste and reduce the probability of use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

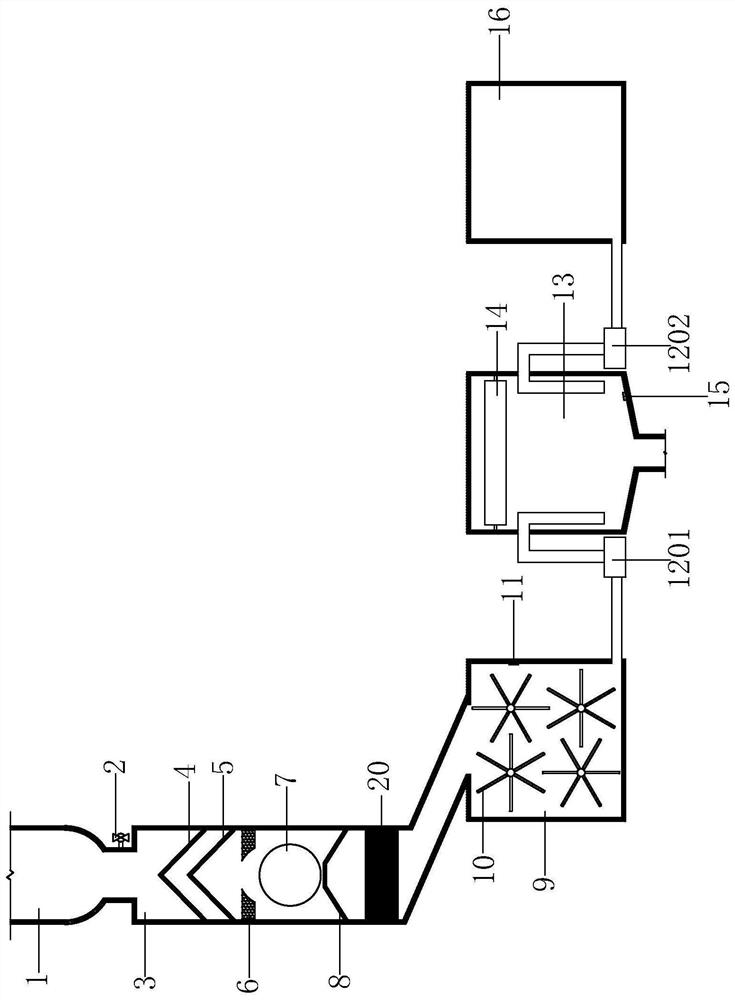

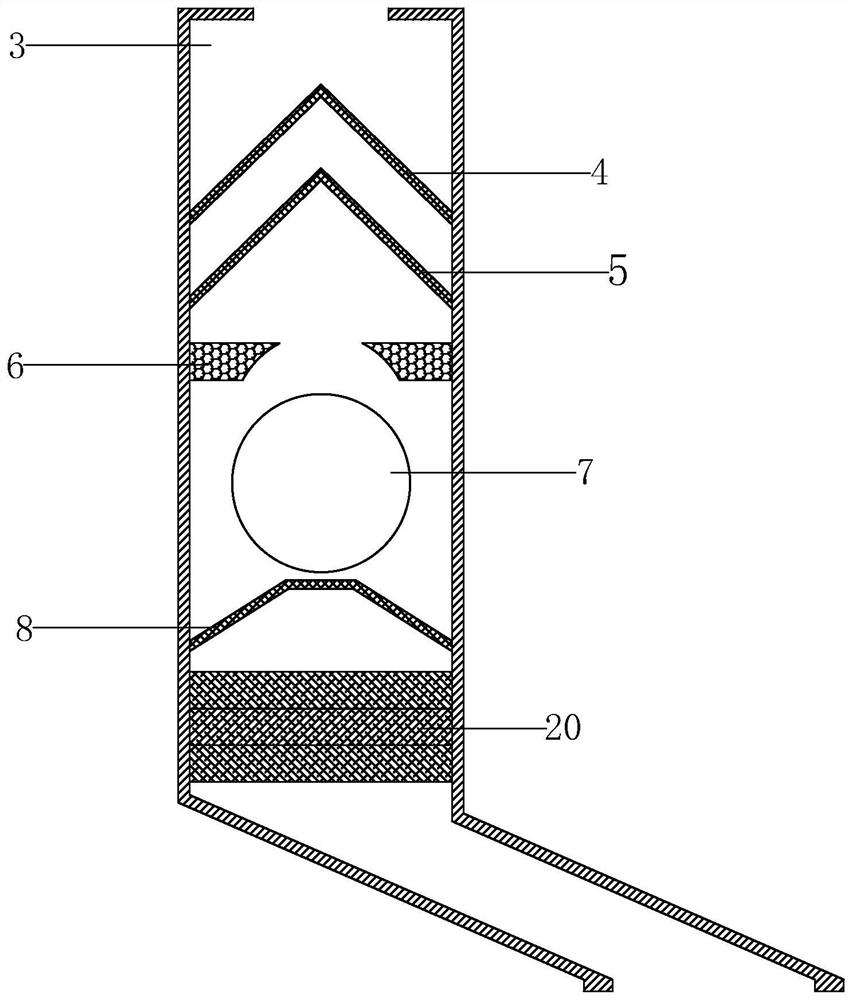

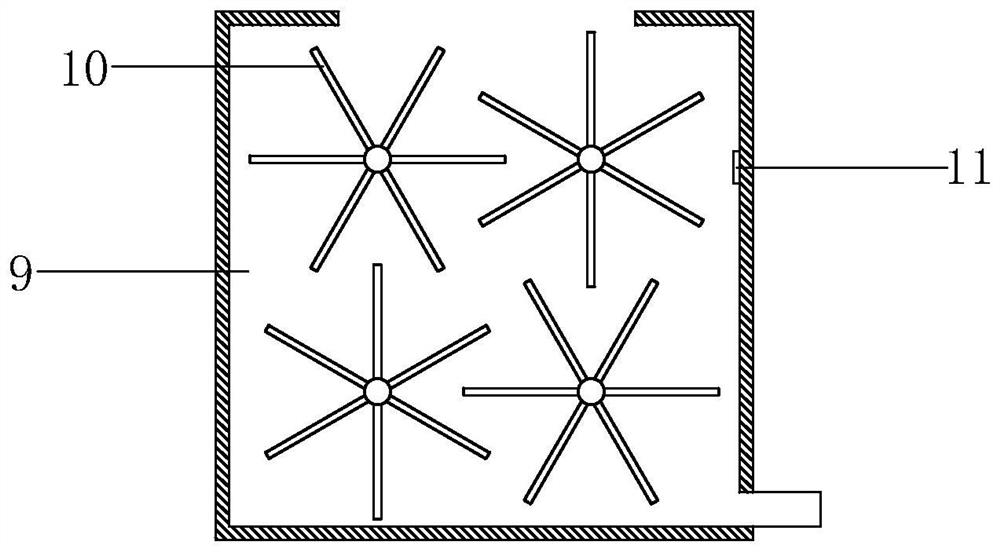

[0023] Specific implementation mode one: as Figure 1 ~ Figure 4 As shown, the present invention discloses an energy-saving water supply system, which includes a water injection pump 1201, a replenishment water pump 1202, a treatment mechanism, a purification mechanism, and a sterilization mechanism; the treatment mechanism includes a treatment pipe 3, a first filter 4, a second filter Net 5, the third filter screen 8, activated carbon layer 20 and anti-reverse mechanism; the purification mechanism includes a purification box 9, a drainage sensor 11 and a plurality of stirring paddles 10; the sterilization mechanism includes a sterilization box 13, an ultraviolet lamp 14 and water replenishing sensor 15; the first filter screen 4, the second filter screen 5, the non-return mechanism, the third filter screen 8 and the activated carbon layer 20 are successively arranged in the described processing pipe 3 from top to bottom, and the processing pipe 3 The drain end is connected to...

specific Embodiment approach 2

[0024] Specific implementation mode two: as figure 1 As shown, this embodiment is a further description of specific embodiment 1. The water inlet end of the processing pipe 3 is provided with a temporary storage tank 1, and a valve 2 is provided between the temporary storage tank 1 and the processing pipe 3. The temporary storage box 1 can temporarily store the sewage when the treatment pipe 3 is overhauled, and the valve 2 can intercept the sewage.

specific Embodiment approach 3

[0025] Embodiment 3: This embodiment is a further description of Embodiment 1 or Embodiment 2. The processing pipe 3 is provided with an inspection port, which is convenient for inspection and maintenance.

[0026] Specific implementation mode four: as figure 1 , 2 As shown, this embodiment is a further description of the third specific embodiment. The non-return mechanism includes a stopper 6 and a non-return ball 7. The stopper 6 is fixed on the inner wall of the processing tube 3. The non-return The ball 7 is freely arranged between the block 6 and the third filter net 8 , and the non-return ball 7 is arranged in cooperation with the block 6 for sealing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com