Converter lance-lifting non-toppling direct tapping method

A technology of down-furnace and converter, applied in the field of metallurgy, can solve the problems of increasing the labor intensity of employees, exceeding the standard of molten steel composition, increasing the power consumption of LF furnace, etc., and achieves the effect of preventing damage to steelmaking equipment, reducing the amount of steel slag, and saving alloy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

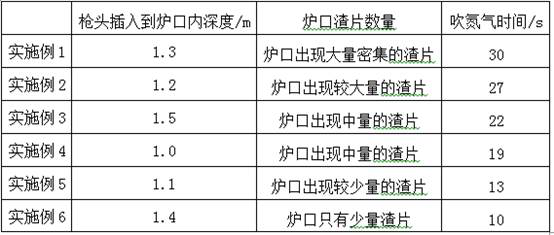

[0015] The invention discloses a method for direct tapping of the converter without turning the furnace down. After the oxygen lance is lifted at the end of the converter blowing process, the oxygen lance is automatically lifted to the waiting position, and the control mode of the oxygen lance is switched to realize manual control of the lance position. The gun head is inserted into the furnace mouth for 1.0-1.5m, and the depth of the oxygen lance head entering the furnace mouth is judged according to the difference between the absolute height of the oxygen lance and the absolute height of the furnace mouth. Open the nitrogen cut-off valve, open the flow regulating valve to 100%, blow nitrogen continuously for 10-30s, and blow away the slag layer in the furnace. The nitrogen blowing time is determined according to the slag splashing from the furnace mouth. After starting nitrogen blowing, if a large number of dense slag flakes appear at the furnace mouth, the blowing time is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com