Failure control method for temperature sensor of automobile particulate filter

A particle trap and temperature sensor technology, which is applied in the field of automobile control, can solve the problems of engine exhaust system back pressure rise, particle trap blockage, carbon accumulation error estimation error, etc., to improve safety and avoid blockage , the effect of avoiding the risk of burning out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following specific embodiments are used to further describe the technical solution of the claims of the present invention in detail, so that those skilled in the art can understand the claims more clearly. The protection scope of the present invention is not limited to the following specific examples. The protection scope of the present invention includes the technical solution of the claims of the present invention made by those skilled in the art and is different from the following specific embodiments.

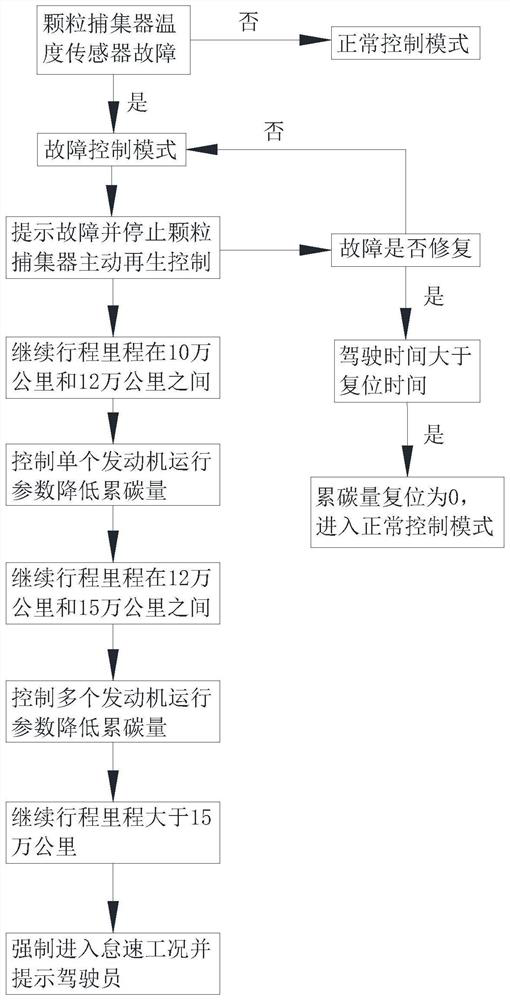

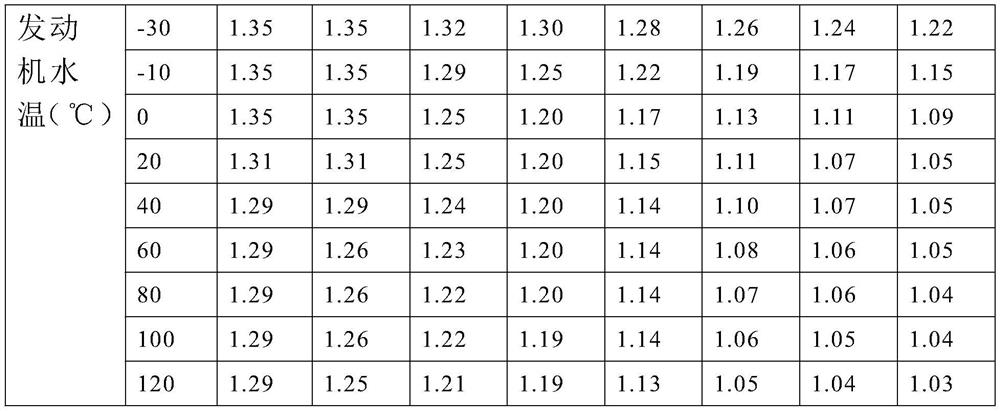

[0023] like figure 1 As shown, a method for controlling the failure of the temperature sensor of the particle filter of the automobile, when no failure of the temperature sensor of the particle filter is detected, it enters the normal control mode, and when the carbon accumulation of the particle filter is greater than the set carbon accumulation , through voice and on-board display to remind the driver that "the particulate filter has too much carbon accumulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com