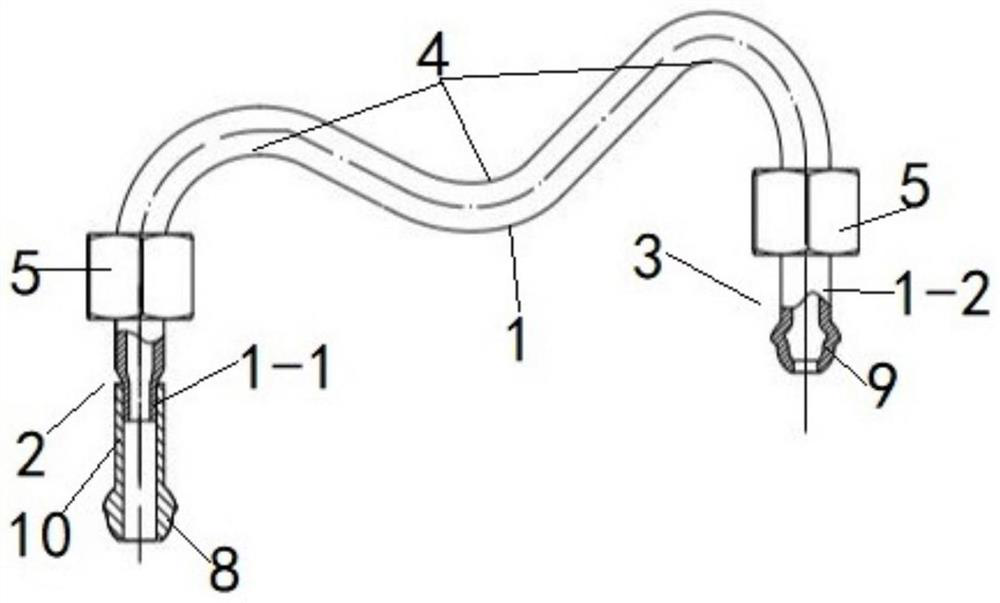

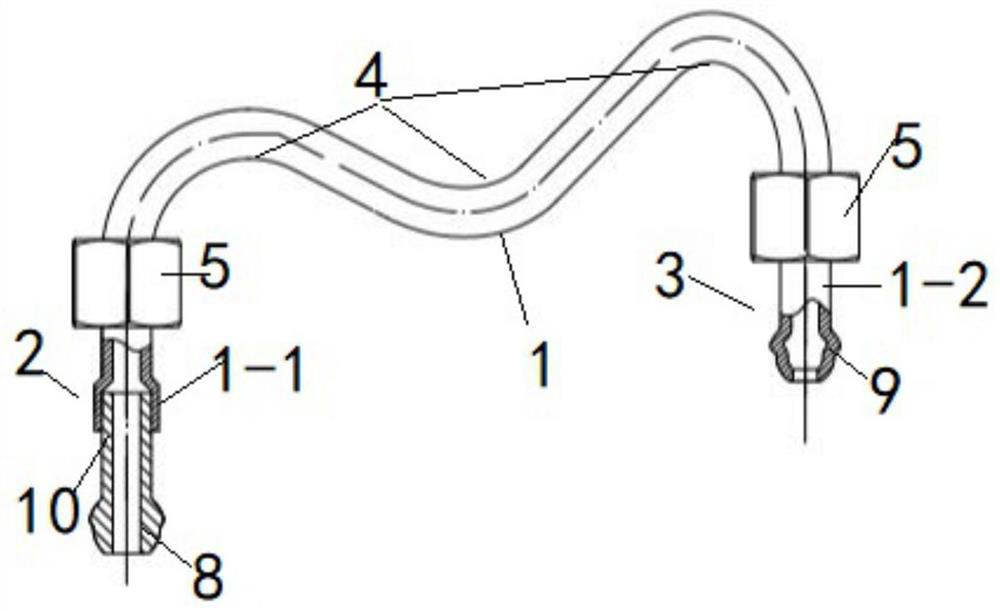

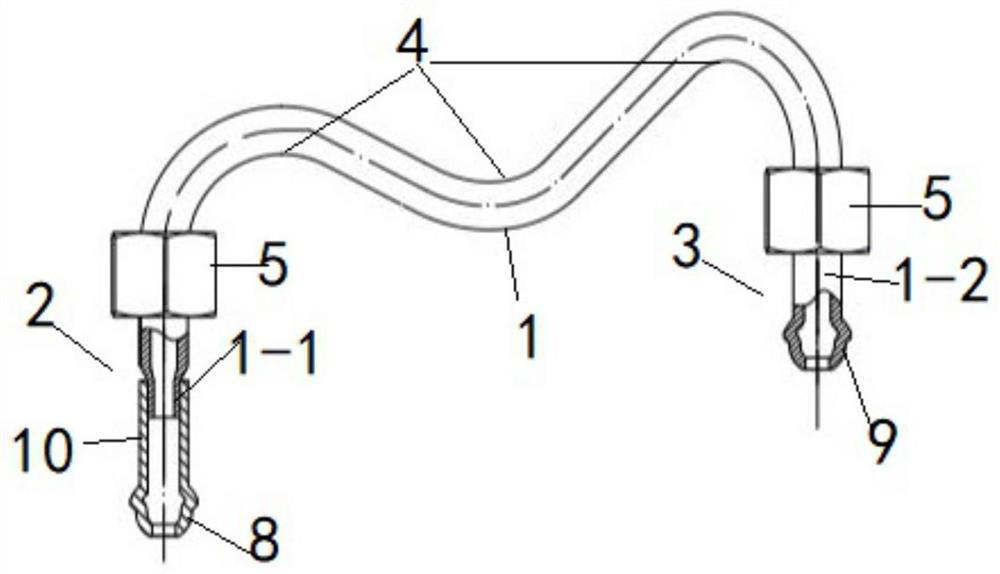

Stainless steel fuel oil high-pressure oil pipe and manufacturing process thereof

A high-pressure oil pipe and manufacturing process technology, which is applied to fuel injection devices, engine components, machines/engines, etc., can solve the problems of reducing the sealing reliability of oil pipes and the decline in nut locking performance, so as to reduce the rigidity of the body, improve the strength, and ensure Effect of Seal Reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 2

[0149] Specific embodiment 2, the stainless steel high-pressure fuel oil pipe provided in this embodiment 2 is the same as the stainless steel high-pressure fuel oil pipe in specific embodiment 1, only the manufacturing process steps of a stainless steel high-pressure fuel oil pipe in this embodiment 2 are simpler, It includes the following steps:

[0150] Step S1: cutting off the raw stainless steel straight pipe;

[0151] Step S2: Assembling the first connector 8 and the copper ring 7 at the end of the cut stainless steel straight pipe; the first connector 8 is preferably the stainless steel machined connector 6 .

[0152] Step S3: performing high-temperature brazing and high-temperature annealing on one end of the stainless steel straight pipe port assembled with the stainless steel machined joint 6 and the copper ring 7 to form a brazed sealing joint 2;

[0153] Step S4: Insert two back-to-back nuts 5 through the unprocessed other end port of the stainless steel straight ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending angle | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap