Ultrasonic cavitation pipetting device for food inspection

A liquid pipetting device and food inspection technology, which is applied to measuring devices, sampling devices, laboratory utensils, etc., can solve problems such as easy generation of air bubbles and inaccurate pipetting, and achieve the effects of preventing pollution and being easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

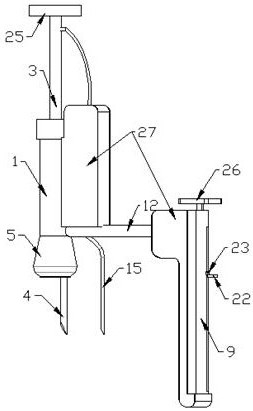

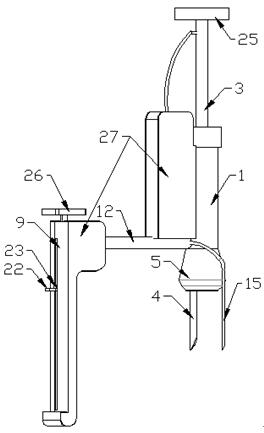

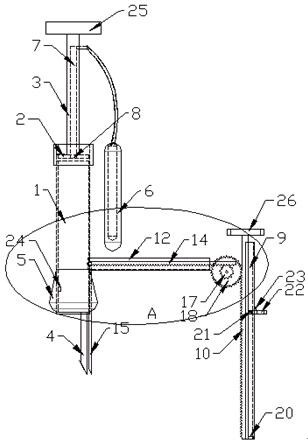

[0042] Embodiment 1: A kind of ultrasonic cavitation pipetting device for food inspection, such as Figure 1-4 As shown, it includes the rough movement system, the fine movement system connected with the rough movement system and the control system;

[0043] The rough movement system includes a rough movement pipe 1, a rough movement piston 2 arranged in the coarse movement pipe 1, a rough movement connecting rod 3 connected with the rough movement piston 2, a fixing piece, and a rough movement suction head 4 connected with the rough movement pipe 1 below , ultrasonic generator 5, air pump 6, air hole 7 and the valve 8 that is arranged on the air hole 7, described up and down is image 3 Above and below the air pump 6 is provided with a casing 27; the coarse pipette 1 is made of a transparent and pressure-resistant material, and the coarse pipette can be made of tempered glass. When pipetting, the amount of liquid volume inside the coarse pipette 1 is increased. The coarse pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com