Stretchable multi-core conductive element and preparation method thereof, stretchable cable and stretchable capacitive sensor

A capacitive sensor and conductive element technology, applied in the direction of extendable conductor cables, electrical components, extendable conductors, etc., can solve the problems that the sensor cannot obtain stretching changes, signal interference, etc., and achieves easy connection and integration, anti-electromagnetic The effect of strong interference and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

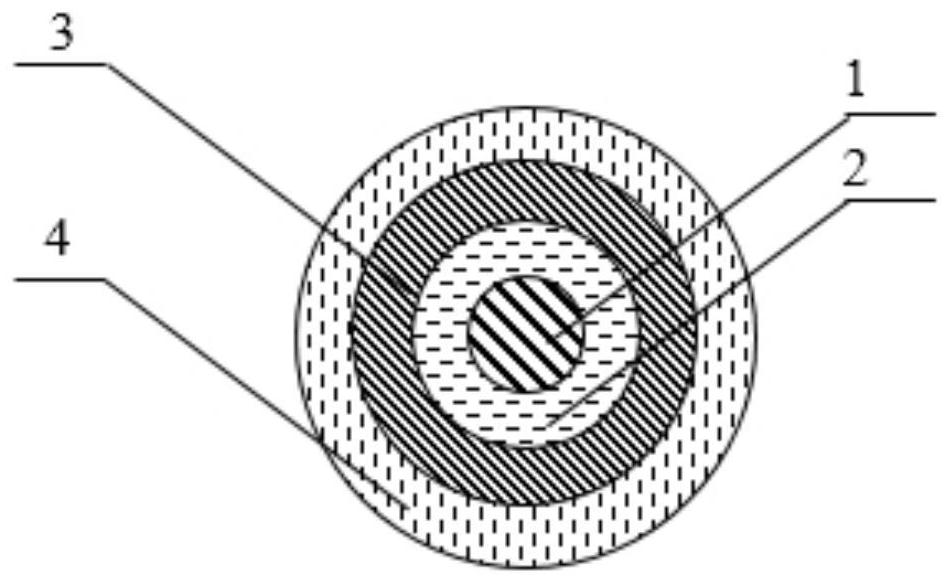

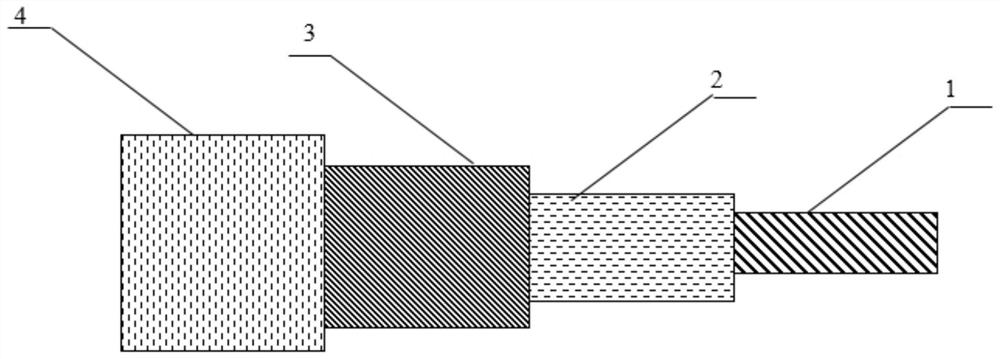

[0052] In this example, if figure 1 , 2 As shown, the stretchable conductive element is composed of an inner layer stretchable wire and an outer layer stretchable wire. The inner stretchable wire consists of a stretchable wire unit. The stretchable wire unit uses liquid metal 1 as a central conductor, and its periphery is covered with an elastic insulating layer 2 . The outer stretchable wire is composed of an elastic conductive shielding material and an elastic insulating material; the elastic conductive shielding material is coaxially wrapped around the inner layer of the stretchable wire to form an elastic conductive shielding layer 3, and the elastic insulating material is coaxially wrapped on the elastic An elastic protective layer 4 is formed around the conductive shielding layer.

[0053] The liquid metal 1 is made of GaInSn alloy; the material of the elastic insulating layer is made of SEBS; the material of the elastic conductive shielding layer is made of liquid me...

Embodiment 2

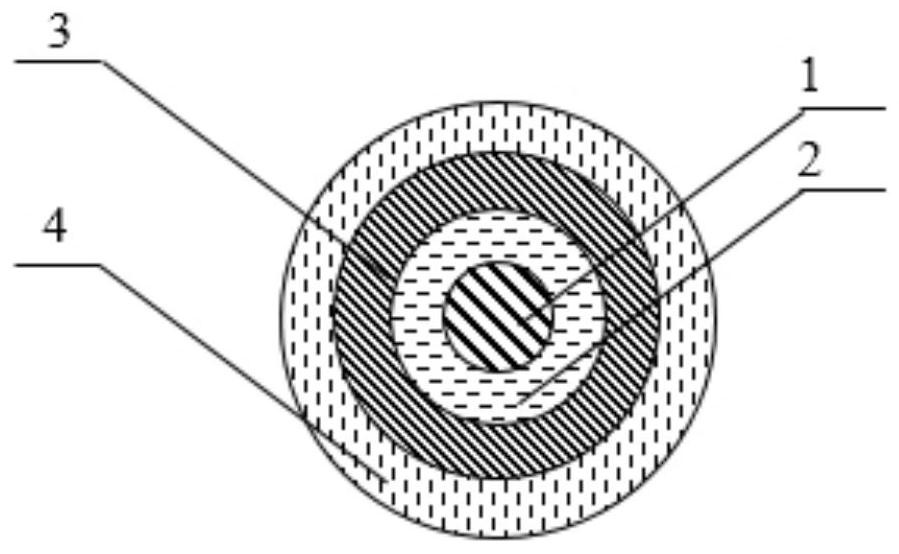

[0059] In this example, if image 3 , 4 , 5, the stretchable conductive element is composed of an inner layer stretchable wire and an outer layer stretchable wire. The inner stretchable wire consists of a stretchable wire unit. The stretchable wire unit uses liquid metal 1 as a central conductor, and its periphery is covered with an elastic insulating layer 2 . The outer stretchable wire is composed of an elastic conductive shielding material and an elastic insulating material; the elastic conductive shielding material is coaxially and intermittently wrapped around the outer periphery of the inner stretchable wire to form an elastic conductive shielding layer 3, and the elastic insulating material is coaxially wrapped An elastic protection layer 4 is formed covering the periphery of the elastic conductive shielding layer.

[0060] The liquid metal 1 is made of GaInSn alloy; the elastic insulating layer is made of polyurethane PU, a thermoplastic elastic material; the elasti...

Embodiment 3

[0066] In this example, if Image 6 , 7 As shown, the stretchable conductive element is composed of an inner layer stretchable wire and an outer layer stretchable wire. The inner stretchable wire consists of two stretchable wire units. Each stretchable wire uses liquid metal 1 as a central conductor, and its periphery is covered with an elastic insulating layer 2 . Such as Image 6 , 7 As shown, two stretchable wire units are arranged in parallel, and their central conductors are parallel to each other along the central axis of the length direction.

[0067] The outer stretchable wire is composed of an elastic conductive shielding material and an elastic insulating material; the elastic conductive shielding material is coaxially wrapped around the inner layer of the stretchable wire to form an elastic conductive shielding layer 3, and the elastic insulating material is coaxially wrapped on the elastic An elastic protective layer 4 is formed around the conductive shielding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com